Fixture for fixing inverted conical surface workpiece

A technology of inverted cones and workpieces, applied in the direction of spraying devices, etc., can solve the problems of inflexible distribution of air-conditioning, air-conditioning waste, etc., and achieve the effects of improved product appearance, convenient use, and guaranteed expansion and tightening accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

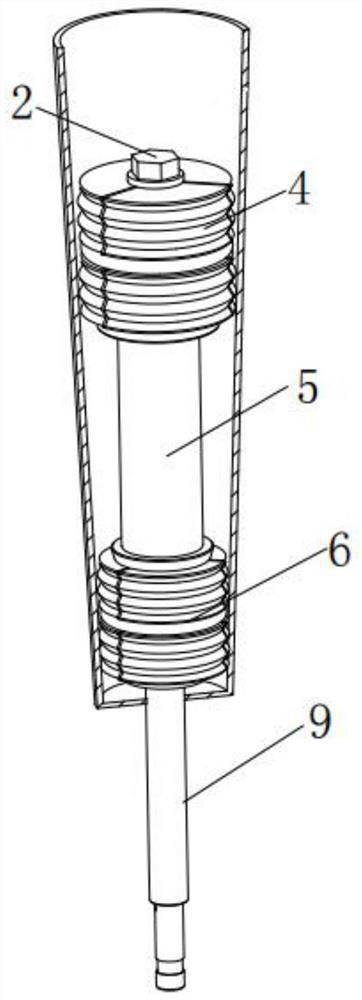

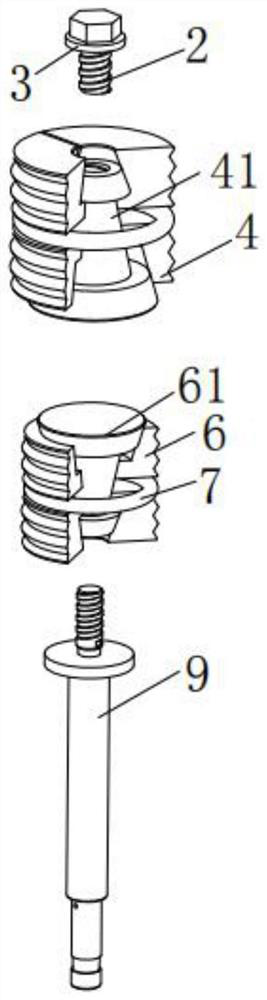

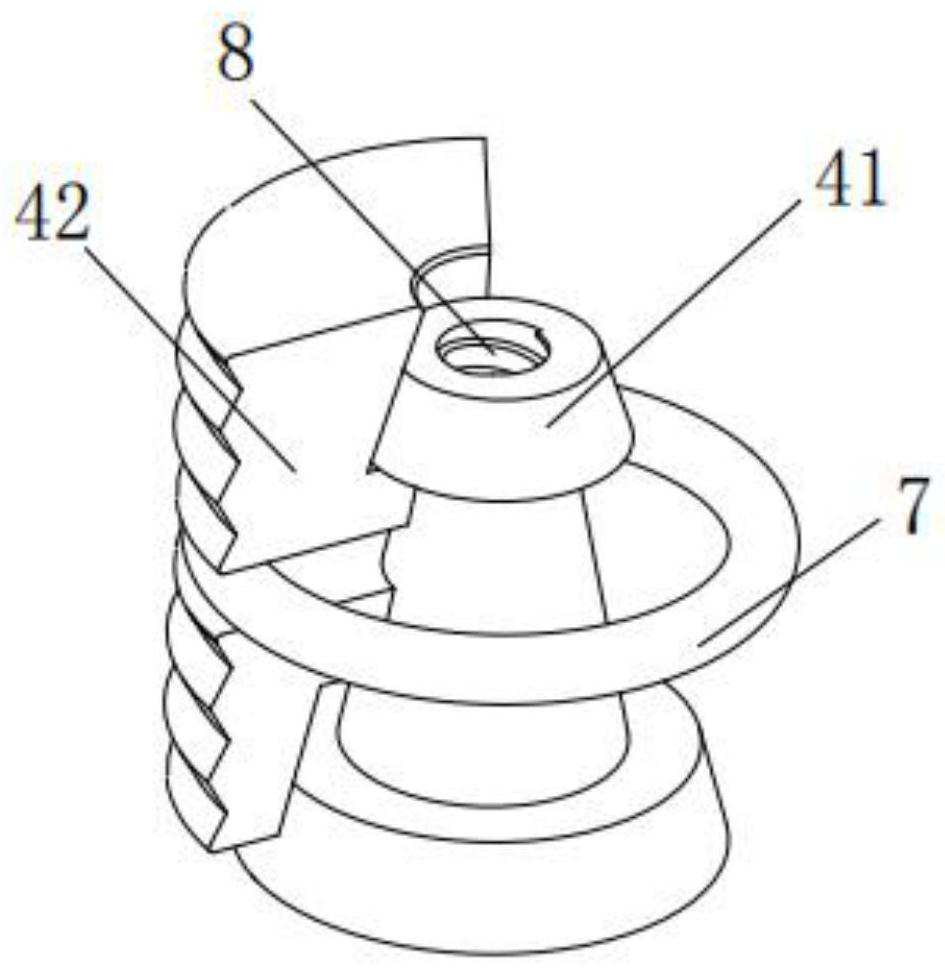

[0039]Working Principle of Embodiment 1: Firstly, the end of the fixture provided with the expansion screw 2 is vertically placed in the inverted conical workpiece, and then the installation rod 9 is inserted from the bottom to the bottom of the lower expansion core 61 inside the lower expansion sleeve 62 , then turn the installation rod 9, and tighten it with the threaded hole 8 at the bottom, and then make the lower expansion core 61 move down, because the lower expansion core 61 is tapered, and the lower expansion sleeve 62 is set as a three-lobed toothed structure, and cooperates with the lower expansion core 61. The arc surface of the core 61 realizes expansion, and then the expansion screw 2 is turned, the expansion screw 2 matches the thread inside the upper expansion core 41, and the setting of the gasket 3 prevents the expansion screw 2 from being connected to the upper expansion sleeve The friction force of 42 is too large, as the expansion screw 2 is tightened, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com