Automatic folding scooter

A scooter, automatic technology, applied in the field of transportation, can solve the problems of not easy to carry, easy to dirty clothes, heavy electric skateboards, etc., to achieve the effect of easy and smooth folding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

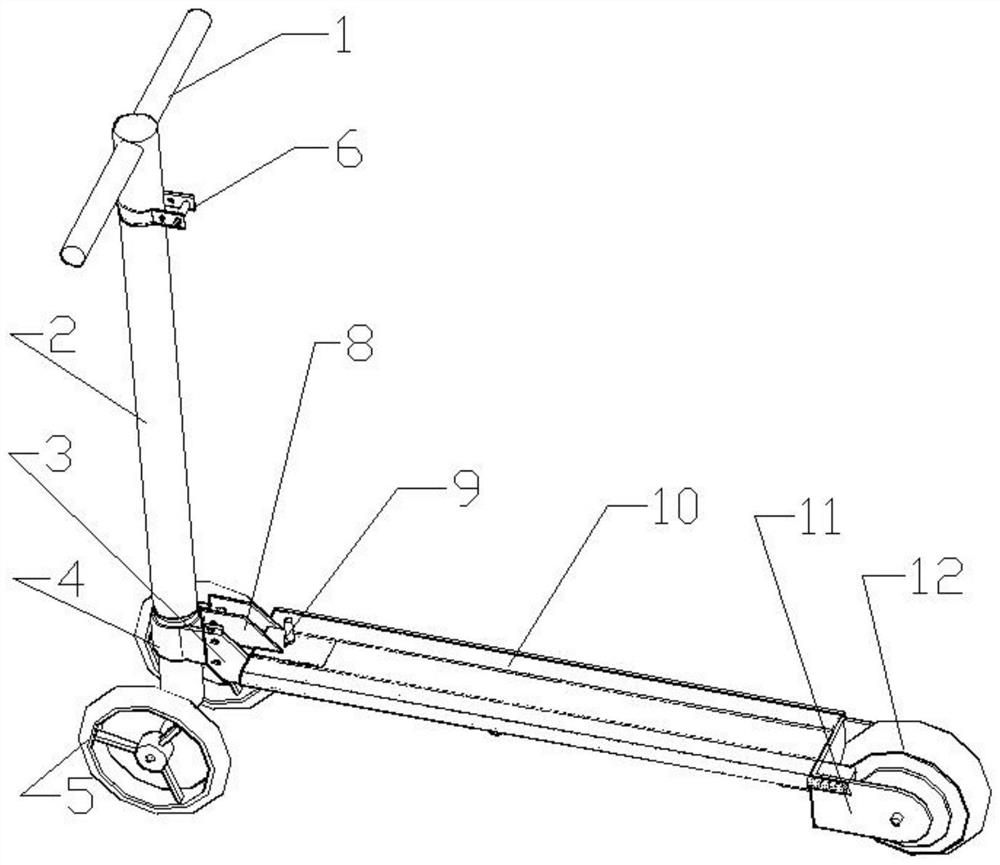

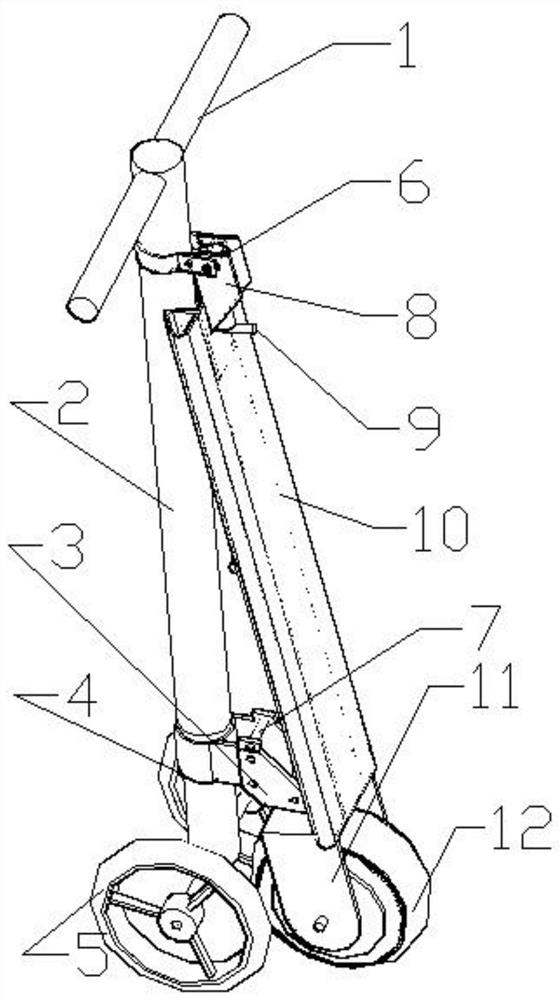

[0035] Such as Figure 1 ~ Figure 3 As shown, the front end shaft 131 of the folding link 13 is connected to the faucet head pipe 4 through the faucet head pipe connector 3, and the end shaft 132 is connected to the middle front part of the plate body 10, and the rear wheel frame 11 and the rear wheel 12 are installed on the rear end of the plate body 10; The groove 8 at the front end of the body and the corresponding stem pin 6, the head pipe pin 7 and the pin clamp 9 constitute a positioning connector.

[0036] When unfolded, the front end of the plate body 10 is quickly detachably connected with the head pipe pin 7 of the faucet head pipe 4, and the front section of the plate body 10, the folding link 13, and the faucet head pipe 4 are partially enclosed to form a triangular structure; the two ends of the folding link 13 rotate respectively Locate at the first positioning point of the faucet head pipe 4 and the front part of the plate body, the groove 8 at the front end of ...

Embodiment 2

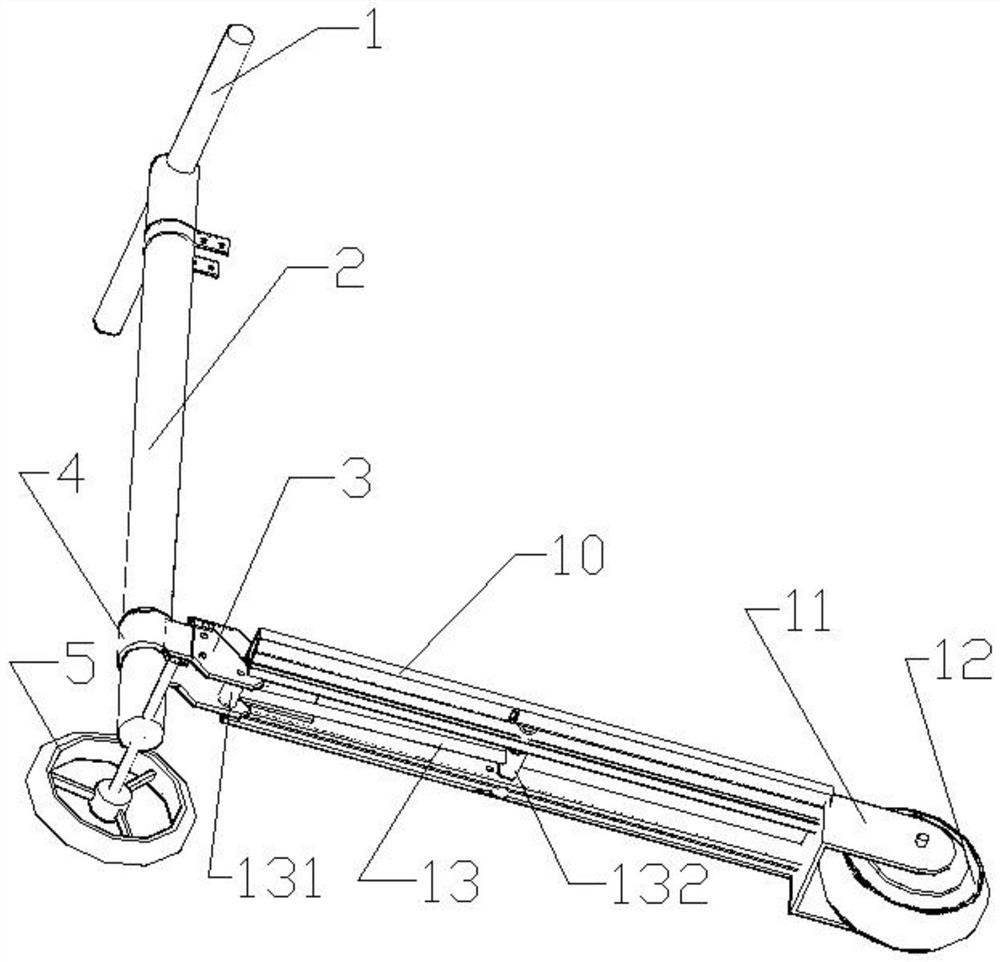

[0038] Such as Figure 4 ~ Figure 6 As shown, the front end shaft 131 of the folding link 13 is connected to the faucet head pipe 4 through the faucet head pipe connector 3, and the end shaft 132 is connected to the middle front part of the plate body 10, and the rear wheel frame 11 and the rear wheel 12 are installed on the rear end of the plate body 10; The groove 8 at the front end of the body and the corresponding stem pin 6, the head pipe pin 7 and the pin clamp 9 constitute a positioning connector.

[0039] When unfolded, the front end of the plate body 10 is quickly detachably connected with the head pipe pin 7 of the faucet head pipe 4, and the front section of the plate body 10, the folding link 13, and the faucet head pipe 4 are partially enclosed to form a triangular structure; the two ends of the folding link 13 rotate respectively Locate the faucet head tube 4 and the first positioning point in the front of the plate body, the groove 8 at the front end of the plat...

Embodiment 3

[0041] Such as Figure 7 ~ Figure 12As shown, the front end shaft 131 of the folding link 13 is connected to the faucet head pipe 4 through the faucet head pipe connector 3, and the end shaft 132 is connected to the middle front part of the plate body 10, and the rear wheel frame 11 and the rear wheel 12 are installed on the rear end of the plate body 10.

[0042] The front end of the folding connecting rod 13 is connected with the multi-directional rotation switch positioning of the faucet head pipe 4, and the end of the folding connecting rod 13 is connected with the multi-directional rotation switching positioning of the front part of the plate body 10; Telescopic pin 15 is arranged, and faucet head tube 4 is provided with head tube positioning concave wheel 18, and the front part in the plate body is provided with plate body positioning concave wheel 19. Each positioning concave wheel is provided with two U-shaped grooves for determining the first positioning point and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com