Disk stack, rotor unit, centrifugal separator, method of providing disk stack and method of providing rotor unit

A technology of centrifugal separator and rotor unit, which is applied in the direction of centrifuge, etc., and can solve problems such as harmful function of centrifugal separator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Aspects of the present invention will now be described more fully. Like numbers refer to like elements throughout. Well-known functions or constructions are not necessarily described in detail for brevity and / or clarity.

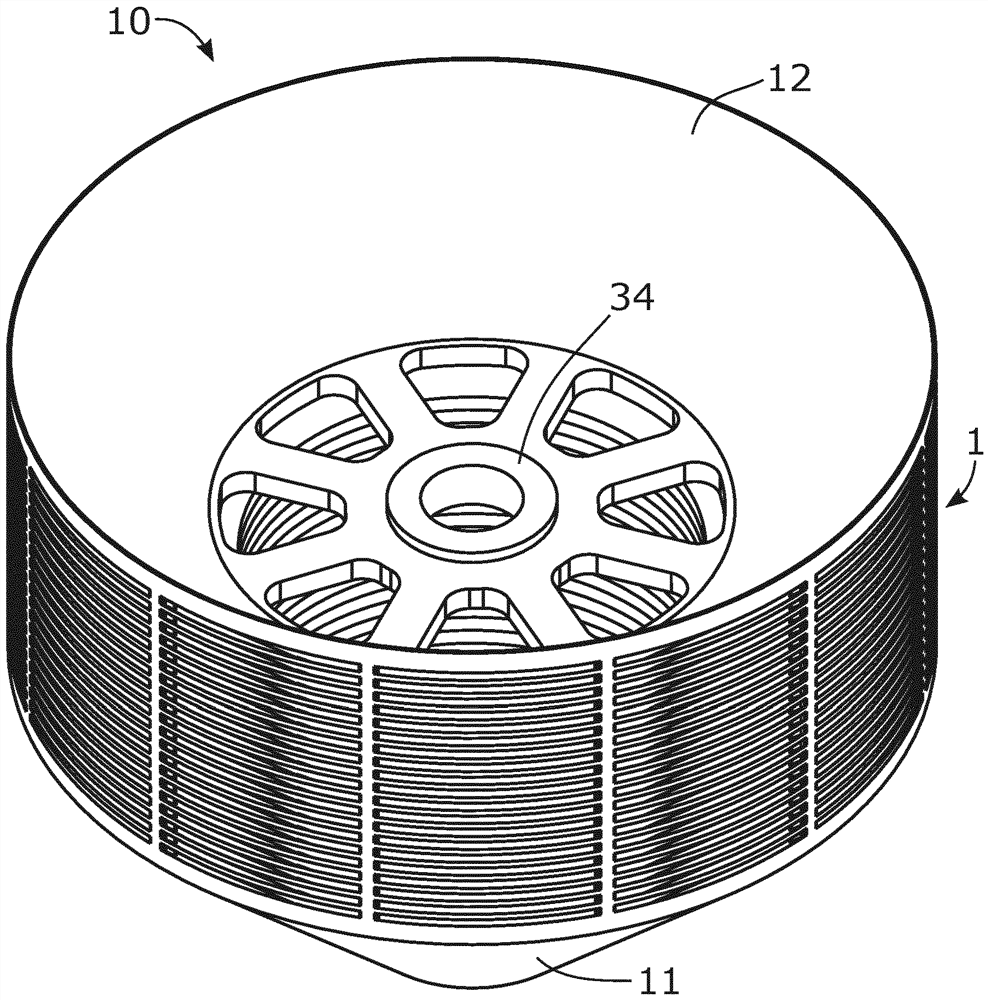

[0068] figure 1 A perspective view of a rotor unit 10 according to some embodiments is shown in an assembled state. The rotor unit 10 is configured to be installed in a separation chamber of a centrifugal separator, such as a crankcase gas separator, as explained further herein. The rotor unit 10 is configured to rotate about the axis of rotation ax during operation in the centrifugal separator in order to separate substances having different densities. According to the illustrated embodiment, the rotor unit 10 comprises a drive shaft 31 for connection to a drive arrangement and a support shaft 32 for connection to a support arrangement, such as a bearing, as explained further herein.

[0069] The rotor unit 10 comprises a disk stack 1 of frusto-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com