Liquid storage box, additive feeding module and identification method of liquid storage box

An identification method and liquid storage box technology, which are applied to the control device of washing machines, textiles and papermaking, and other washing machines, etc., can solve the problems of wrong addition of additives, inability to accurately determine the installation position of the liquid storage box, and misplacement, etc. Accurate identification, suitable for promotion and use, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

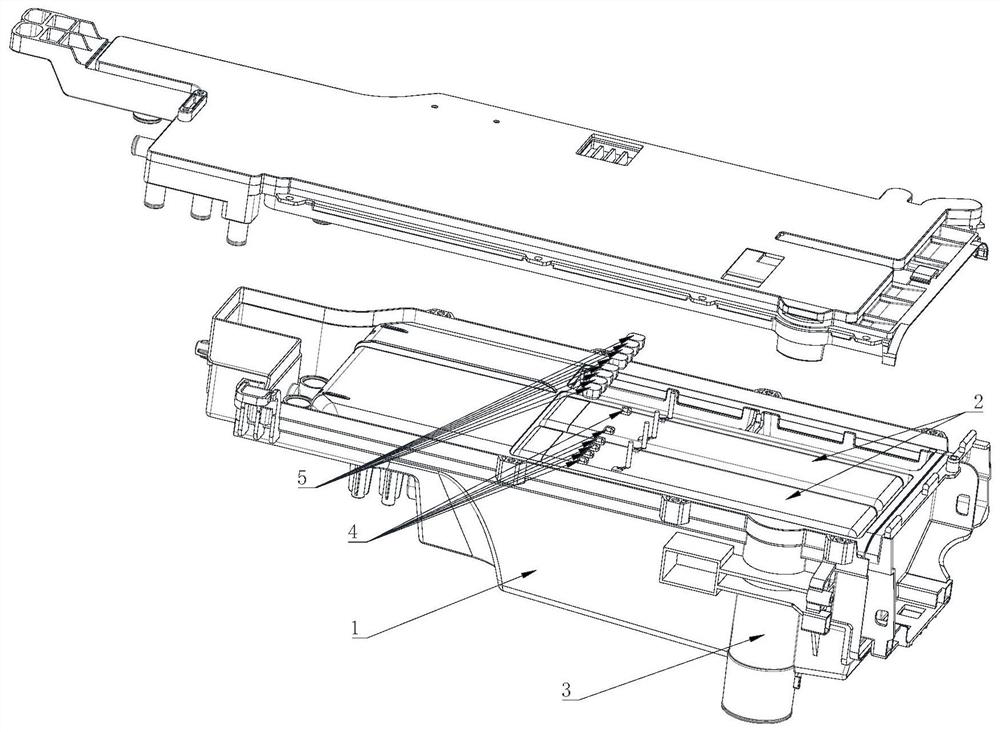

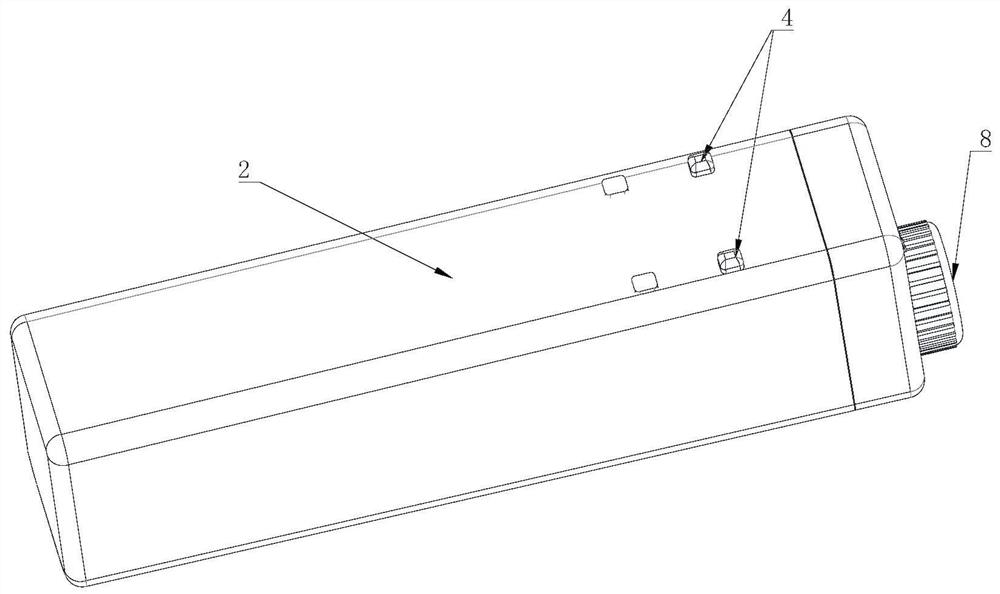

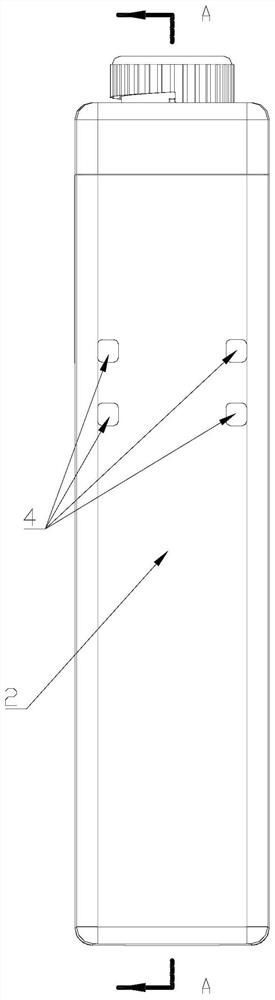

[0058] like Figure 2 to Figure 5 As shown, this embodiment introduces a liquid storage box, the liquid storage box 2 has a sealed chamber 7 for storing additives, the outer wall of the liquid storage box 2 is provided with a concave and convex portion 4, the liquid storage box The position of the concave-convex portion provided on the upper portion corresponds to the type of additive stored in the liquid storage box. In this embodiment, concave and convex portions 4 located at different positions are provided on the outer wall of the liquid storage box 2 for storing different kinds of additives.

[0059] In this embodiment, the concave-convex portion 4 is a protrusion that protrudes outward from the outer wall of the liquid storage box 2 , or is a groove that is concave inward from the outer wall of the liquid storage box 2 . In this embodiment, for the convenience of description in the drawings, the concave-convex portions are shown as protrusions protruding outward from th...

Embodiment 2

[0066] like Image 6 and Figure 7 As shown, this embodiment introduces a liquid storage box, the liquid storage box 2 has a sealed chamber 7 for storing additives, and the outer wall of the liquid storage box 2 is provided with first concave-convex parts spaced apart 41 and the second concave-convex portion 42 , and the distance between the first concave-convex portion 41 and the second concave-convex portion 42 corresponds to the type of additive stored in the liquid storage box 2 .

[0067] In this embodiment, the distance includes distance information between the first concave-convex portion 41 and the second concave-convex portion 42 , relative spatial orientation information, position information set on the liquid storage box 2 and the like.

[0068] For example: as Image 6 As shown, the distance between the first concave-convex portion 41 and the second concave-convex portion 42 provided on the detergent liquid storage box 2 for the detergent is 1 cm, and the rinse a...

Embodiment 3

[0072] This embodiment also has the following technical features based on the above-mentioned embodiment:

[0073] like Figure 2 to Figure 9 As shown, this embodiment introduces a liquid storage box, the liquid storage box 2 has a sealed chamber 7 for storing additives, and the outer surface of the liquid storage box 2 is provided with more than two concave and convex parts 4 , the two concave-convex parts 4 are separated by a distance, so that each concave-convex part 4 is distributed in different positions of the liquid storage box 2 in a way of changing positions, and the number and position of the concave-convex parts 4 set on the liquid storage box 2 are different. The combination corresponds to the type of additive stored in the reservoir.

[0074] In this embodiment, the quantity information of the concave-convex portions 4 is the number of concave-convex portions 4 provided on the outer surface of the liquid storage box 2; for example:

[0075] like Figure 8 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com