High-frequency direct-current and alternating-current ion slurry generator

An ion plasma and generator technology, applied in the field of air purification and disinfection, can solve the problems of inability to objectively reflect the disinfection and purification effect of products, ineffectiveness, low efficiency, etc., and achieve the effect of efficient disinfection and purification process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

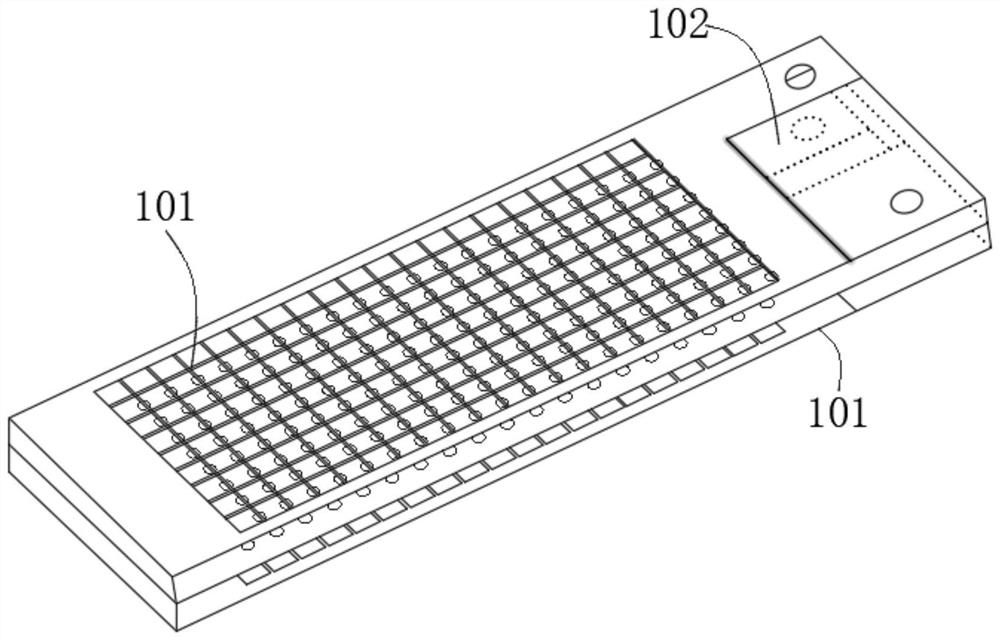

[0029] This embodiment provides a high-frequency DC and AC ion plasma generator, which includes a low-voltage component, a high-voltage component, and a dielectric barrier layer.

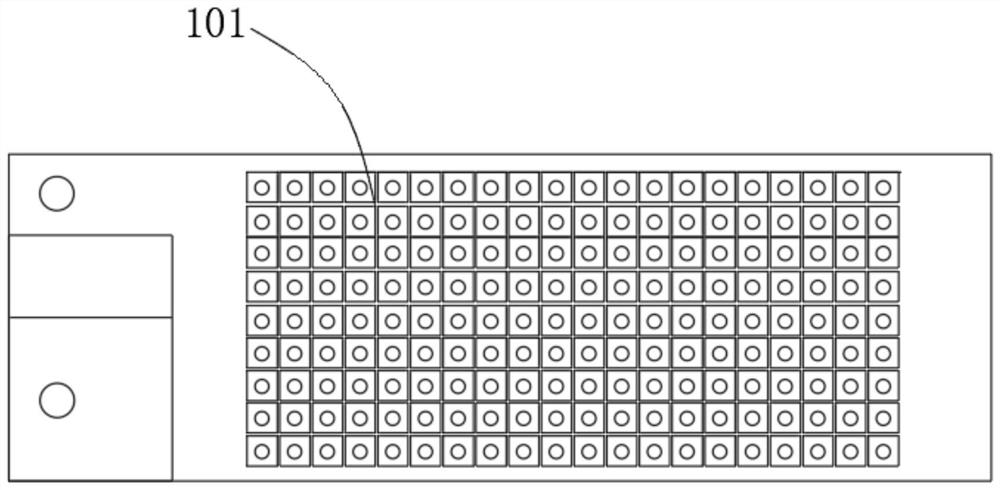

[0030] In the high-frequency alternating current, two low-voltage components are located on the upper and lower surfaces of the three-layer PCB, respectively, and the low-voltage components are composed of square cells with a center-symmetrical pattern, and are arranged in an array structure.

[0031] The high-voltage component is located in the middle layer of the three-layer PCB, and is composed of a circular hole unit with a centrally symmetric pattern, and is arranged in an arrayed structure. The composition effect of the high-voltage components is mainly made of metal plates.

[0032] The square cells of the low-voltage pole of the ion plasma generator are matched with the round-hole cells of the high-voltage pole one by one, which is conducive to generating a larger area and more uniform ion p...

Embodiment 2

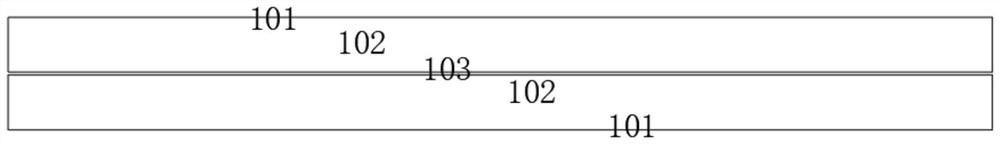

[0034] This embodiment provides a high-frequency DC and AC ion plasma generator, which includes a dielectric barrier plate with a certain thickness, and the dielectric plate from top to bottom includes two pairs of dielectric barrier discharge electrodes composed of three layers of electrodes: low-voltage electrodes, high-voltage electrodes, and low-voltage electrodes. Yes, and each layer of electrodes is separated by a certain thickness of dielectric.

[0035] In the high-frequency AC voltage, the three-layer electrodes include two low-voltage electrodes and one high-voltage electrode. The high-voltage electrodes of the two pairs of dielectric barrier discharge structures are located inside the dielectric plate, and the low-voltage electrodes are located on the surface of the dielectric plate. The high-voltage pole is composed of arrayed circular holes, and the low-voltage pole is composed of arrayed cells. Among them, the pattern center points of the arrayed unit combination...

Embodiment 3

[0037] This embodiment provides a high-frequency DC and AC ion plasma generator. Three layers of electrode patterns with characteristic shapes and matching methods are drawn on a PCB board with a multi-layer circuit function, and formed by an array of unit discharges. The entire discharge generator is conducive to the formation of large-area and uniform discharge. Through the design of the cooperation between the high-voltage electrode and the low-voltage electrode, the metal coverage area of the high-voltage electrode in the unit can be enlarged as much as possible, and the low-voltage electrode can be reduced as much as possible. The metal coverage area greatly improves the distribution range of the active particles generated by the discharge, and the metal on the three-layer electrode layer is gold-plated.

[0038] Further, by designing arrayed low-voltage electrodes and high-voltage electrodes and selecting materials of suitable thickness as the dielectric barrier layer f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com