High-voltage line butt joint device for electric power engineering construction and use method

A technology for power engineering and high-voltage lines, which is applied in the directions of line/collector parts, circuits, connections, etc., and can solve the problems of loosening, breaking, and breaking of high-voltage lines in the connection between the wire and the connector at the break.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

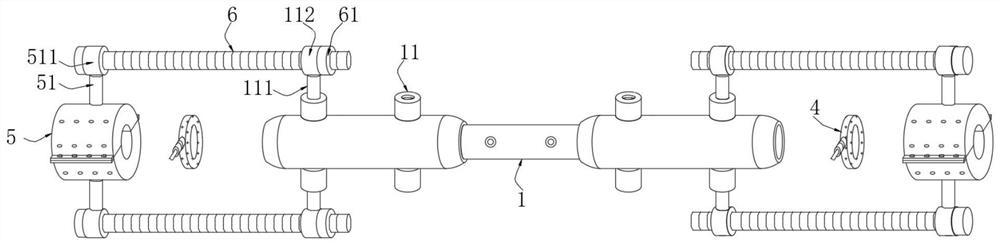

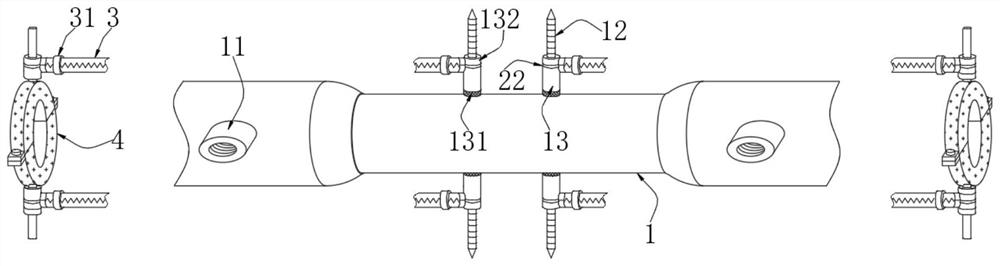

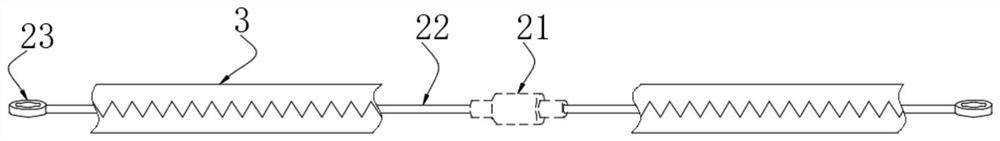

[0029] see Figure 1-Figure 6 , a high-voltage line butt joint for power engineering construction, including a butt joint body 1, a tension detection component 2, a first snap ring 4 and a second snap ring 5, and the two ends of the butt joint body 1 are screwed and fixed with alignment bolts 11. The top of the bolt 11 is screwed and fixed with a connecting rod 111, a section of the connecting rod 111 away from the alignment bolt 11 is fixedly connected with a connecting ring 112, and four symmetrically distributed support rods 12 are fixedly connected to the butt joint body 1, and the support rods 12 are close to the docking One end of the connector body 1 is screwed and fixed with a support block 13, and one end of the support block 13 close to the butt connector body 1 is fixedly connected with a rubber block 131. The two ends are fixedly connected with a pull rope 22, and one end of the pull rope 22 away from the tension sensor 21 is fixedly connected with a fixing ring 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com