Pleated filter element for air filter

An air filter, filter technology, used in dispersed particle filtration, machine/engine, jet propulsion, etc., to solve problems such as increased pressure drop and limited space for adding binders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

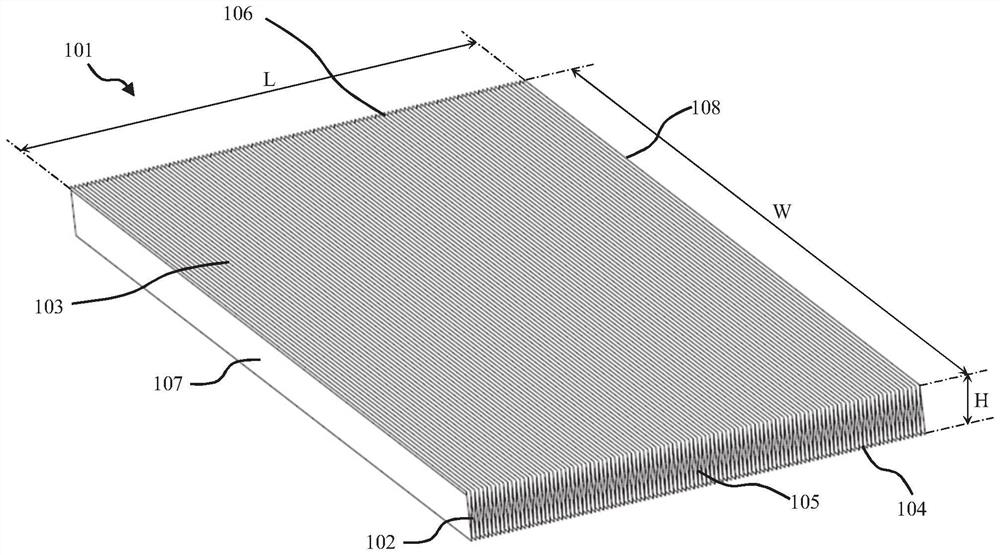

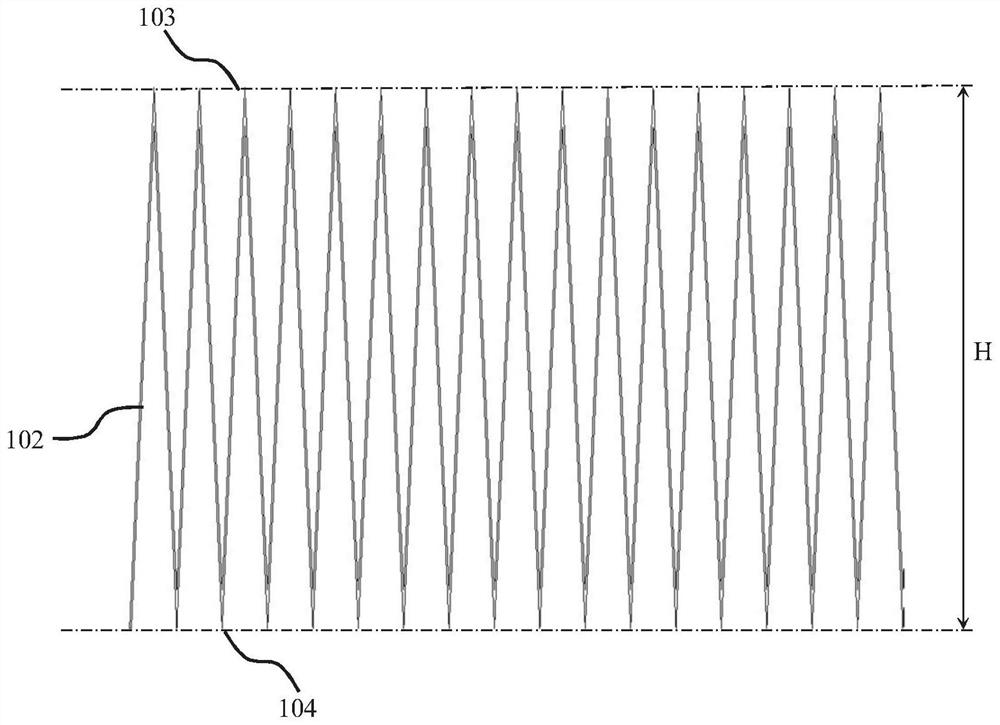

[0080] Figures 1a and 1b illustrate a prior art pleated filter element. Pleated filter elements may be arranged in the housing to form an air filter, such as a panel filter, a deep pleated box filter or a V-shaped filter. Pleated filter element 101 includes pleated filter media 102 . Pleated filter element 101 has a main upstream face 103 and a main downstream face 104 and includes a plurality of opposing facing pleats extending between the main upstream face and the main downstream face such that the pleated The filter element includes a first corrugated edge 105 and a second corrugated edge 106 and a first non-corrugated edge 107 and a second non-corrugated edge 108 . The pleated filter element 101 is rectangular in shape, and the dimensions of the filter element are determined by the length L between the first non-corrugated edge 107 and the second non-corrugated edge 108 in the direction perpendicular to the pleat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com