Electric lamp

A technology of protective cover and light source, applied in the field of type lamp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

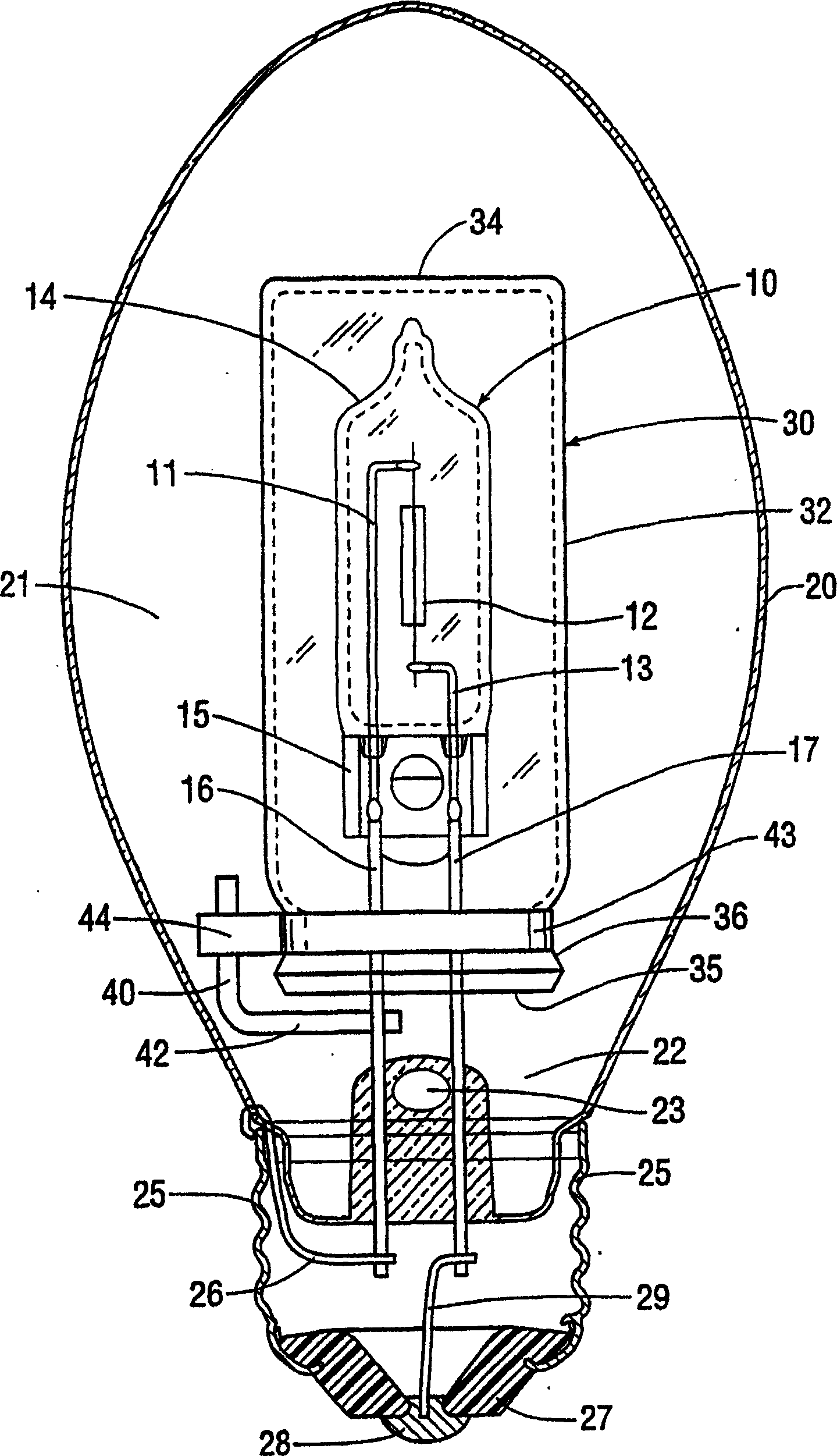

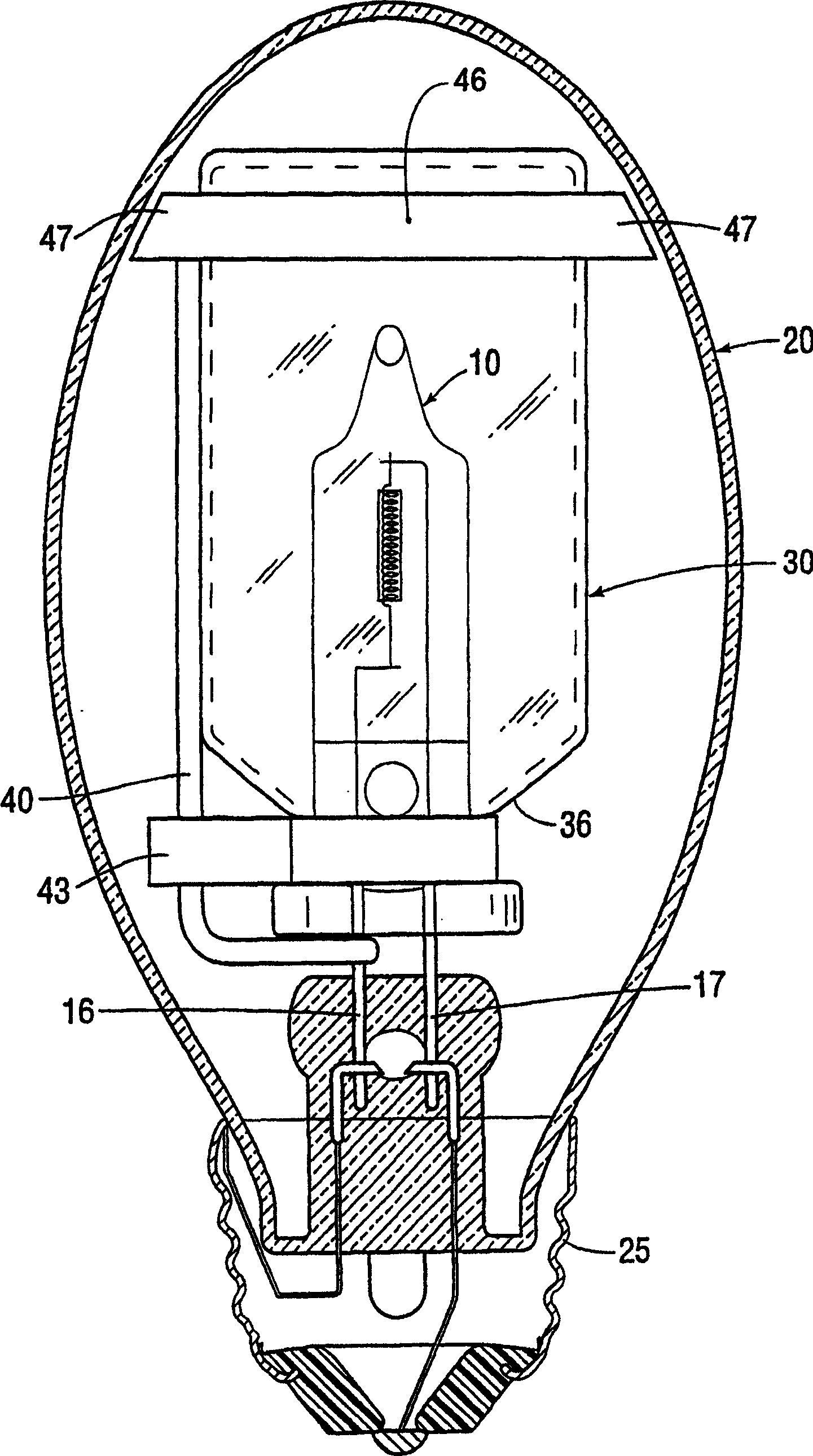

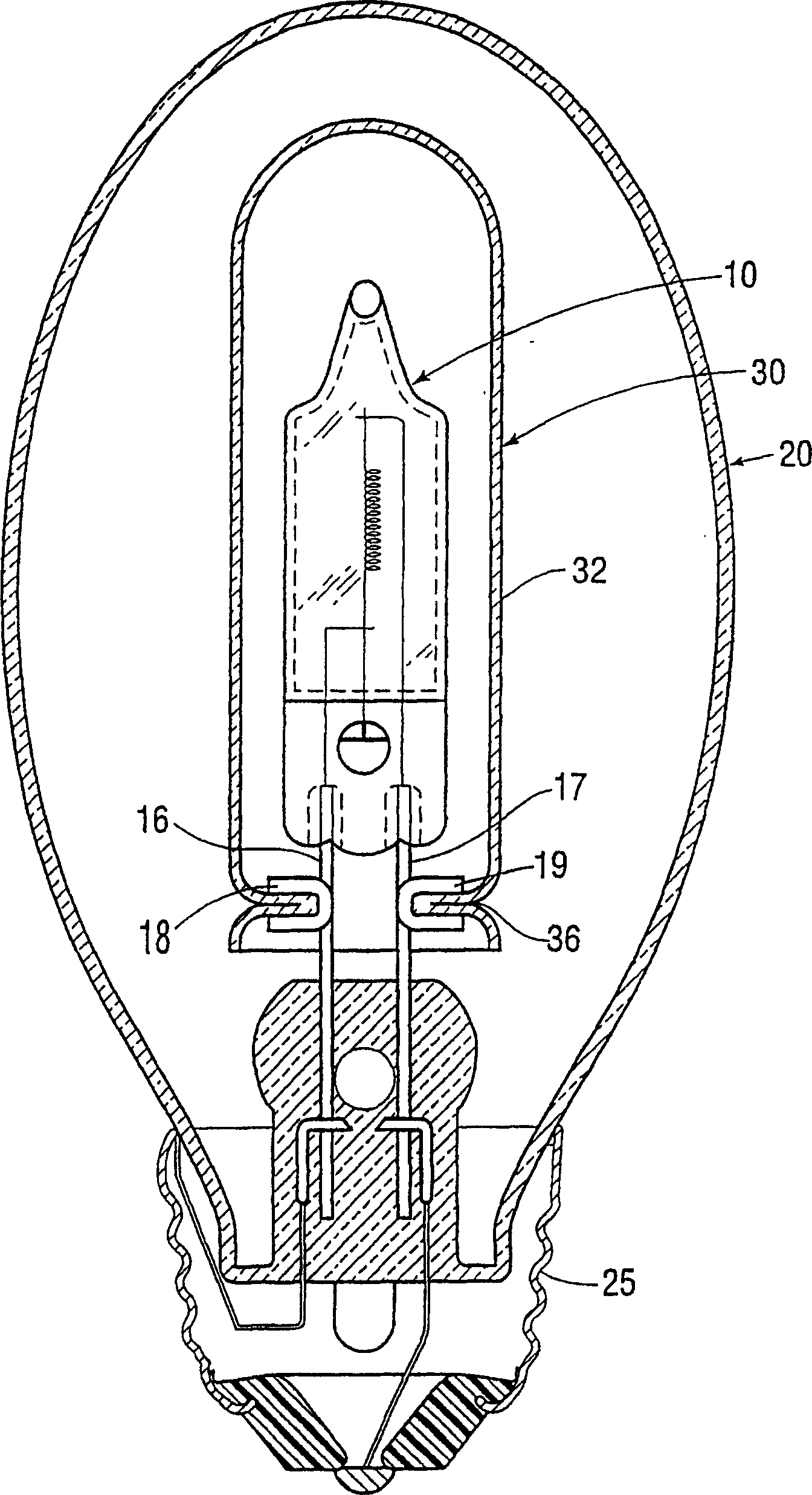

[0018] refer to figure 1 The light source 10 is a tungsten-halogen incandescent lamp, which has a first inner lead 11, a second inner lead 13 and a tungsten filament 12 therebetween. The bulb 14 has at one end a clamp 15 in which the inner leads 11, 13 are connected in known manner to respective outer leads 16, 17 to facilitate sealing. The outer leads 16 , 17 extend outward from the clamp 15 substantially in parallel.

[0019] A glass bulb 20 surrounds a filling space 21 and is fixed to a glass stem 22, which is formed with a suction port 23, which is closed after pumping. The outer leads 16, 17 are sealed directly to the glass stem 22 without any bending or welding, so they are the same leads as the input leads in the glass stem. A conductive base 25 is fixed to the bulb 20 and is electrically connected to the first outer lead 16 through the base lead 26 . A conductive center contact 28 is secured to base 25 by insulating epoxy 27 and is electrically connected to second l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap