AC plasma display panel

A plasma and display panel technology, applied in the direction of static indicators, gas discharge electrodes, tube structure components, etc., can solve the unfavorable adjustment of X and Y electrode spacing, increase the spacing of partition walls 6, and affect the phosphor Visible light luminous efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

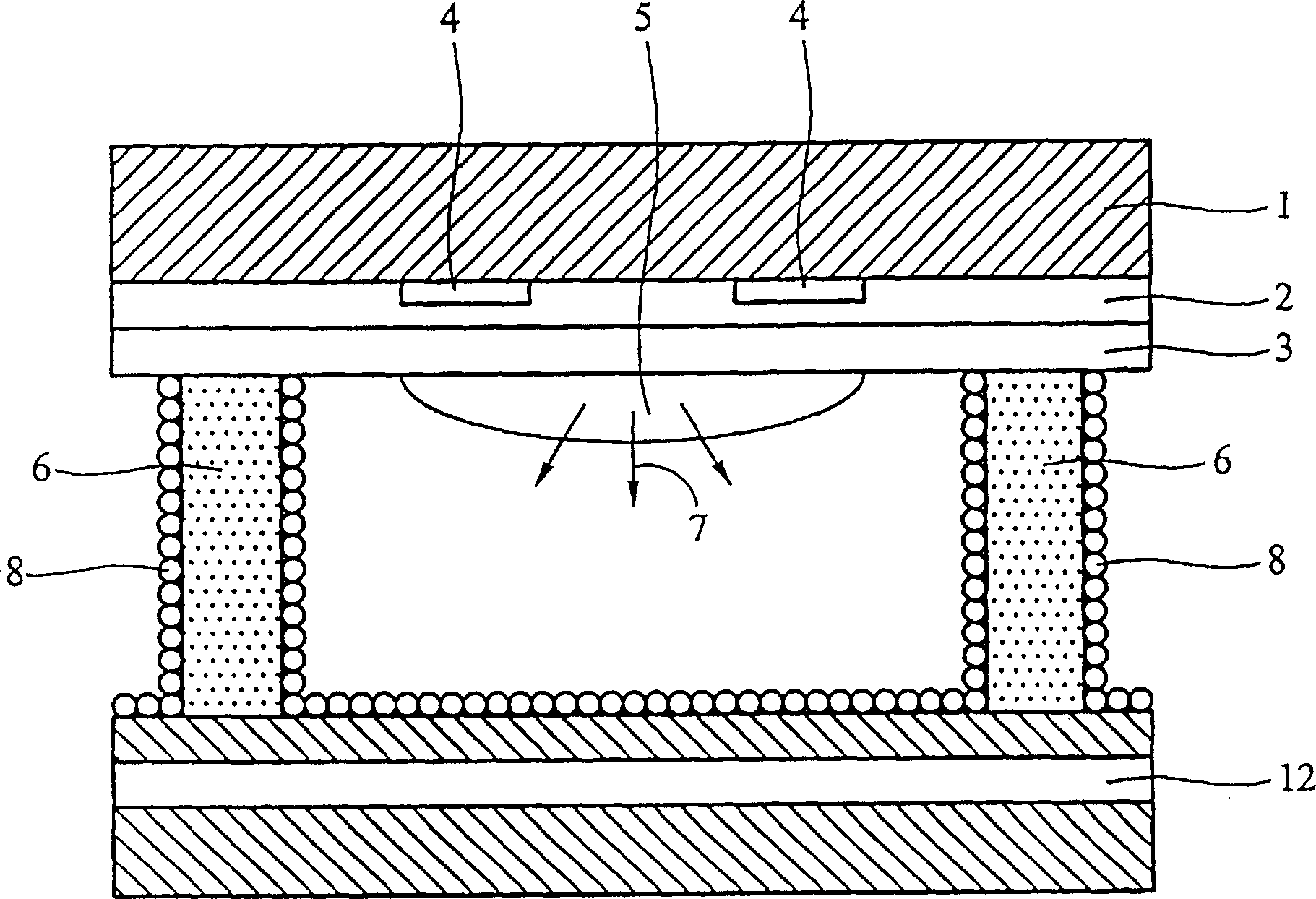

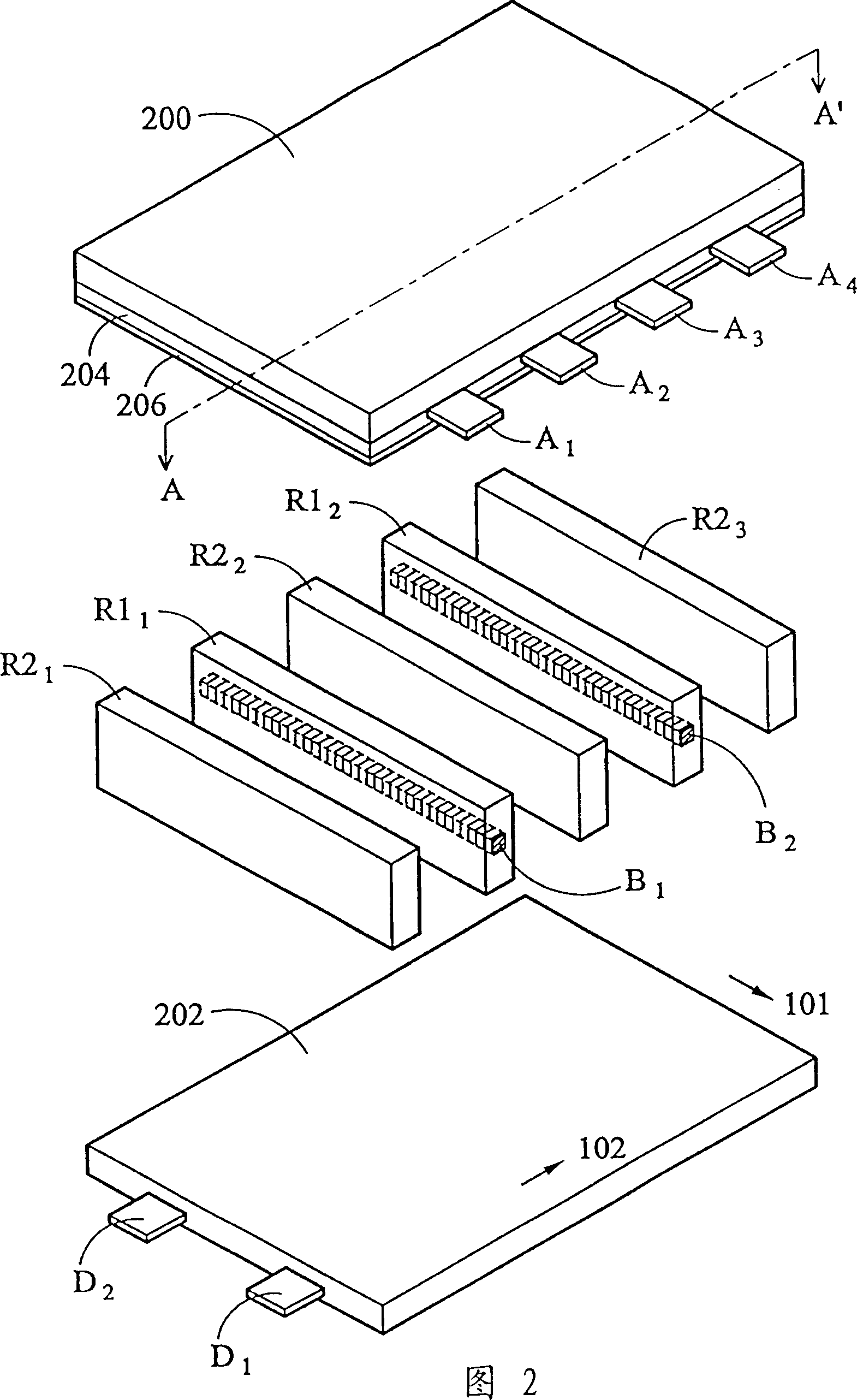

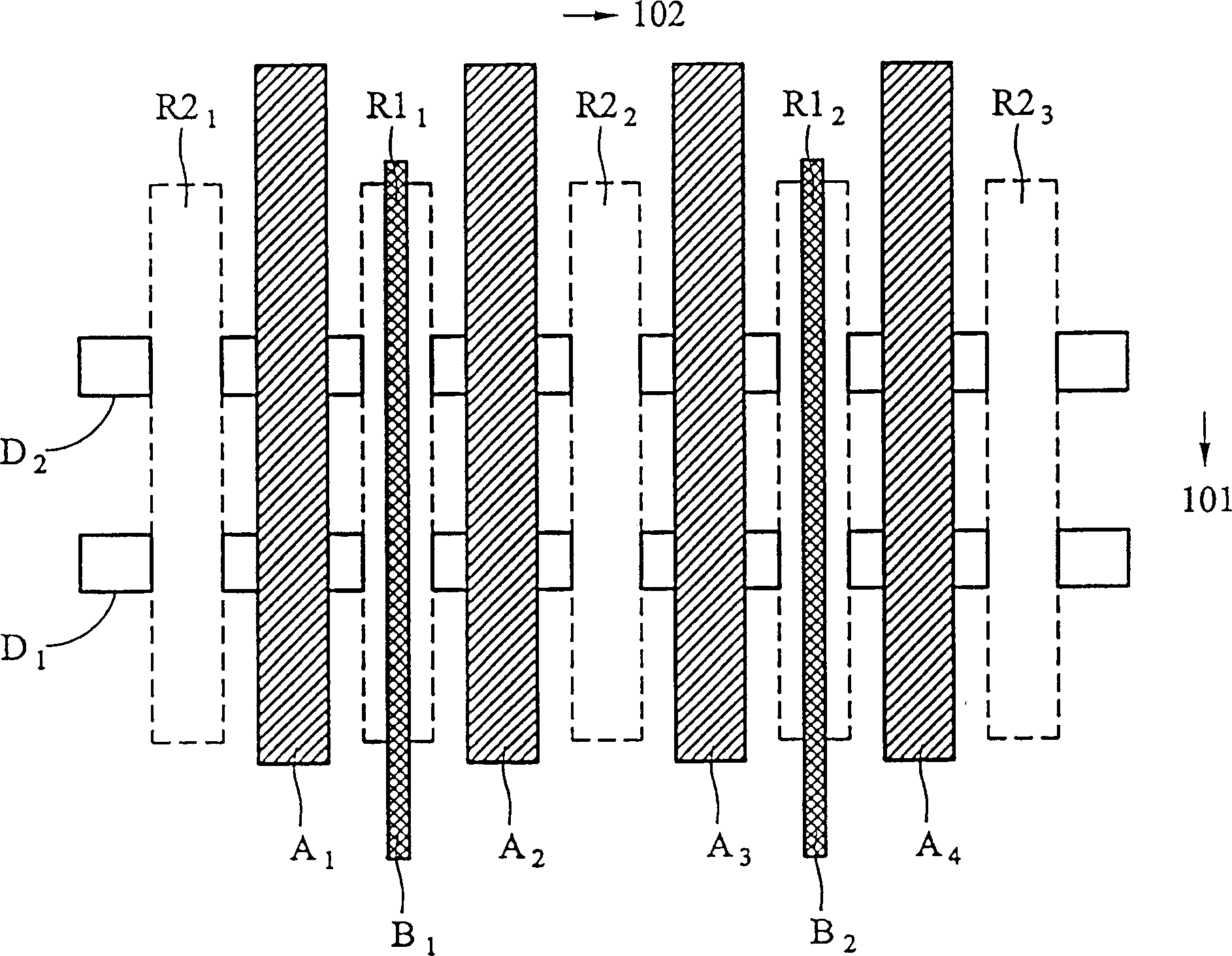

[0051] FIG. 2 is a schematic diagram showing the structure of the AC plasma display panel of the present invention. image 3 It is a plan view showing the electrode arrangement of the AC plasma display panel shown in FIG. 2 .

[0052] Referring to Fig. 2, the AC plasma display panel of the present invention includes: a first substrate (front glass substrate) 200; a first electrode (A i , i=1~4), which is arranged on the first substrate 200 along the first direction 101; a second substrate (rear glass substrate) 202, which is arranged parallel to the first substrate 201 so that the first A discharge space is formed between the substrate 200 and the second substrate 202; a first strip-shaped partition wall (R1 j , j=1~2) and a second strip partition wall (R2 k , k=1~3), they are arranged in the discharge space parallel to each other along the first direction 101 and interlaced with each other; a third electrode (D m , m=1˜2), disposed on the second substrate 202 along the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com