A method and apparatus for determining the resistivity of a formation through which a cased well passes

A technology of resistivity and casing, which is applied in the direction of electrical/magnetic detection for well logging records, and can solve the problems of complicated length and increase of measuring devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

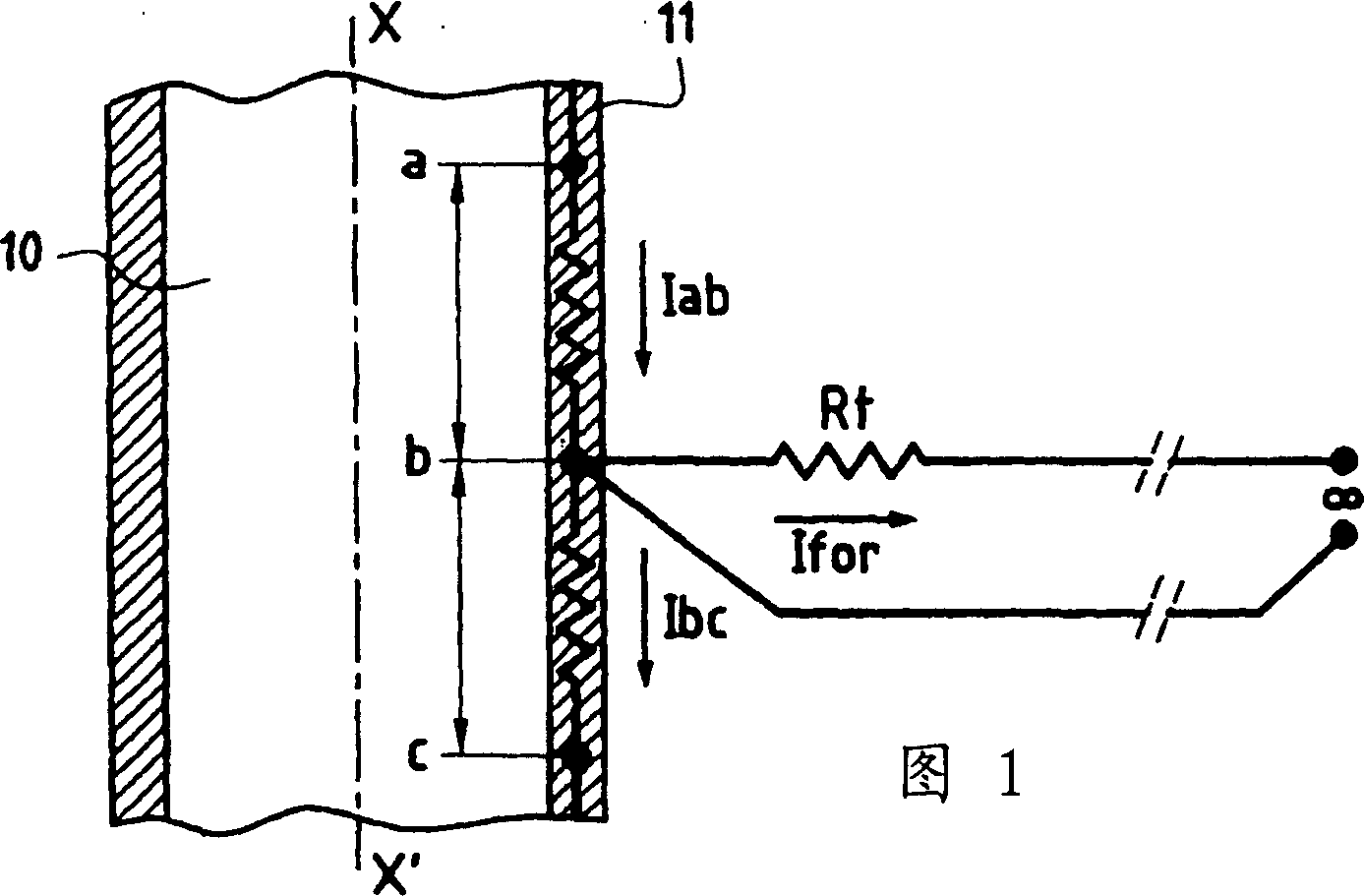

[0019] The principle of measuring resistivity in a cased well is to cause a current flowing along the casing with a distant backflow, so that the current can leak to the formation through which the oil well passes to estimate the leakage current: at any point down the oil well At a given location, the higher the conductivity of the formation surrounding the well, the greater the leakage current. This can be expressed mathematically as a function of the ratio of the formation resistivity Rt to the casing resistivity Rc at any given location by the exponentially decreasing relationship of the current flowing through the casing, with a certain rate of decline .

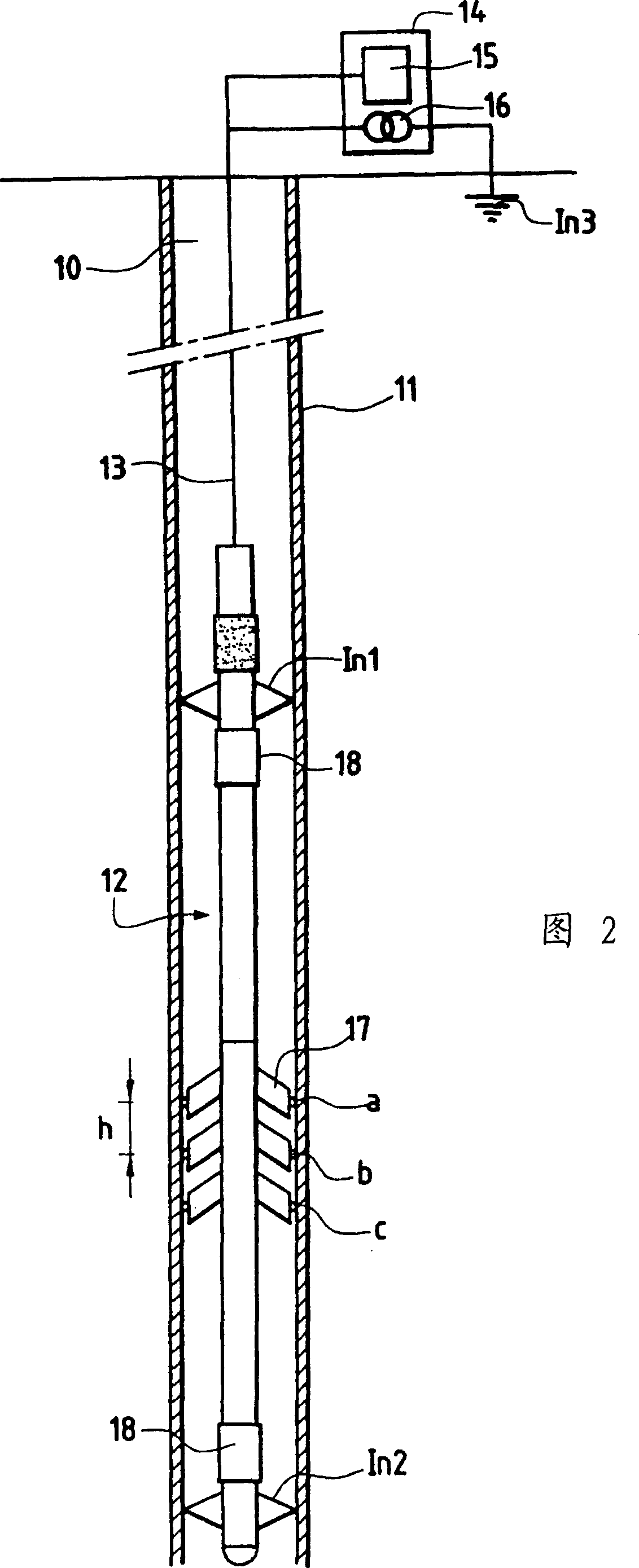

[0020] The diagram in Figure 1 shows a section of a well 10, having an axis XX' and equipped with a metal casing 11. The desired position (or depth) to which a determination is to be made is referenced to the symbol b . Examine the stretch in position b A length of casing on both sides (a, c). If the current flows t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com