Thermosensitive switch

A thermal induction and switching technology, applied in thermal switches, thermal switch components, electrical switches, etc., can solve problems such as deformation, adverse effects of temperature characteristics of bimetal 14, and increased thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

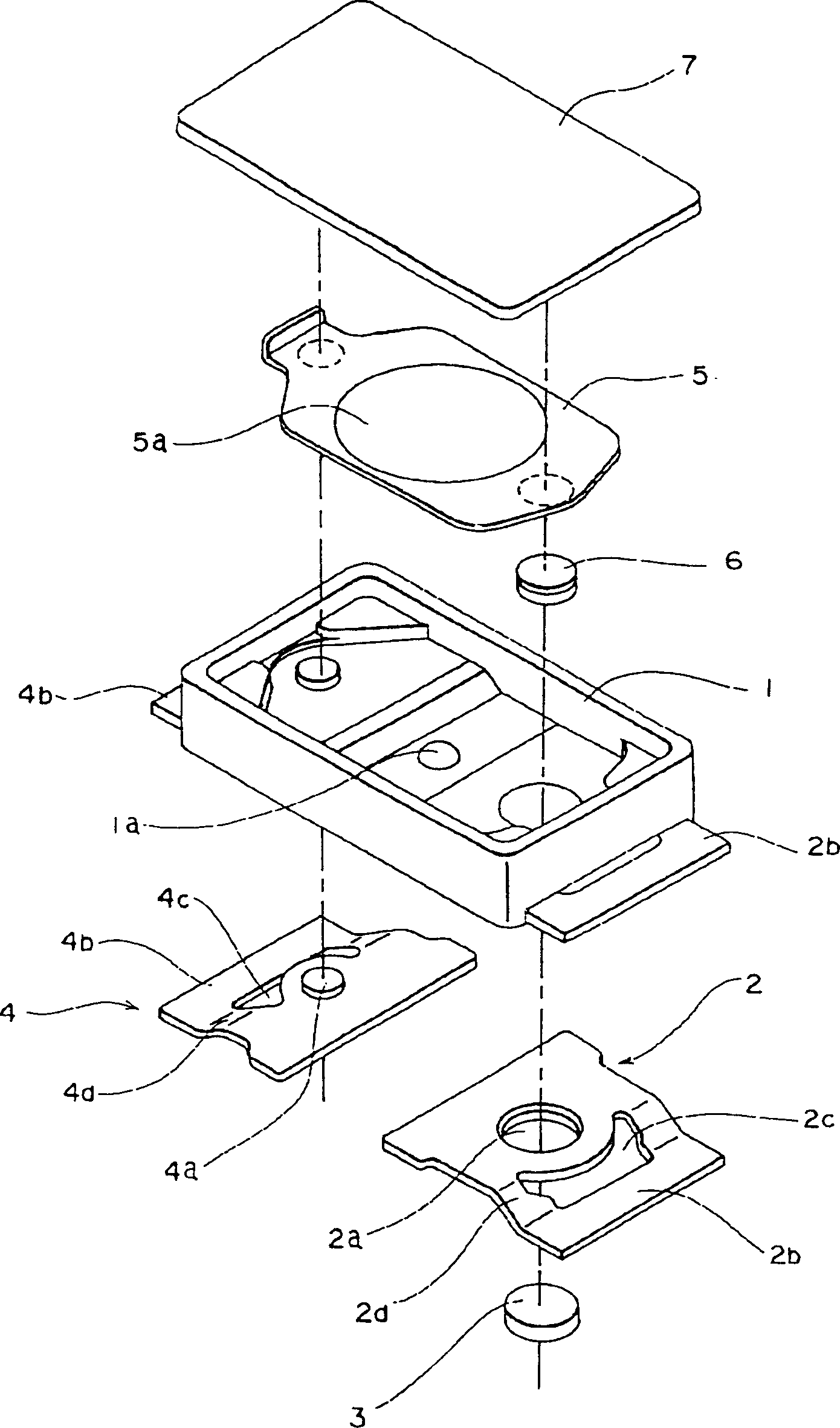

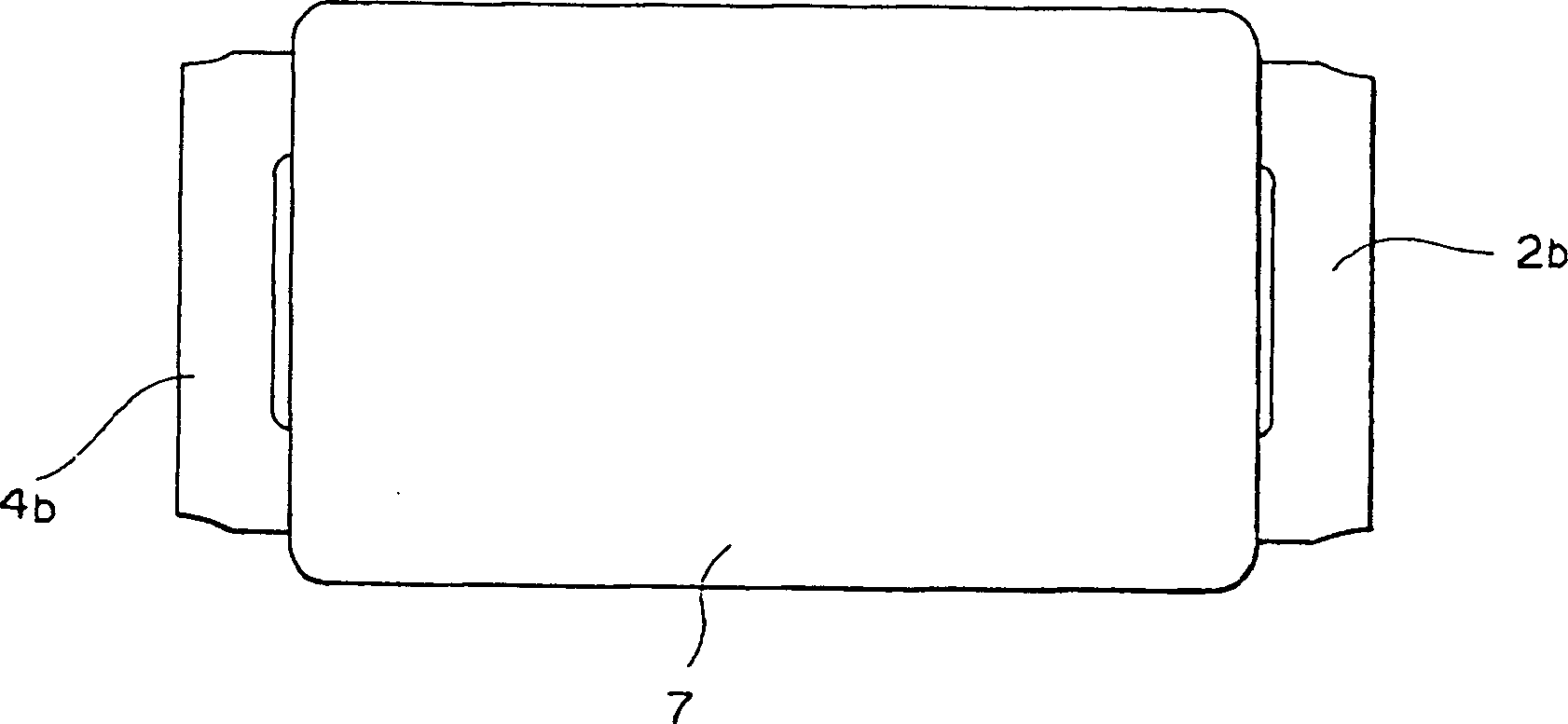

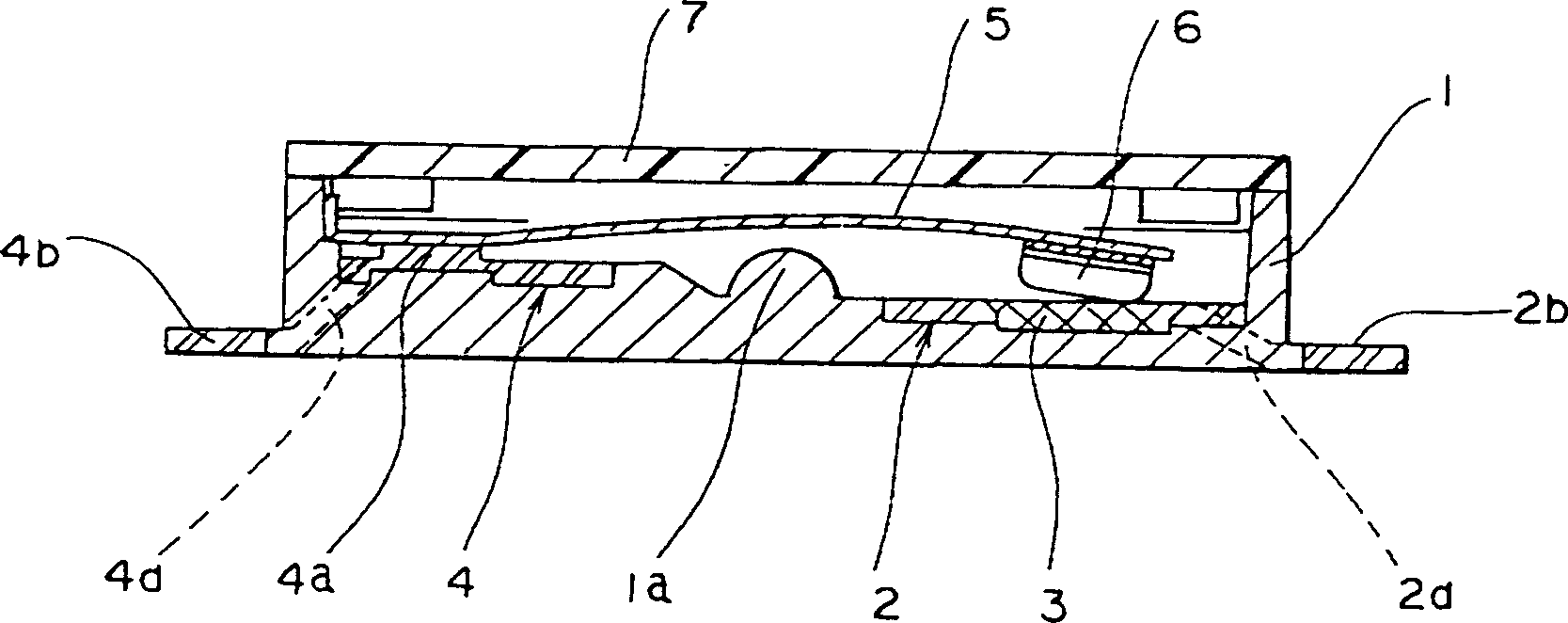

[0033] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0034] as Figure 1 to Figure 9 As shown, the insulating case 1 may be composed of an insulating material such as synthetic resin, and may be formed in a box shape with an open top. Various terminals as described later may also be arranged at the inner bottom of the insulating case 1 , and one end of each terminal is led out from the two side surfaces of the insulating case 1 to the outside. Further, at the central portion of the inner bottom surface of the above-mentioned insulating case 1, a supporting protrusion 1a protruding in a hemispherical shape from the inner bottom surface is provided.

[0035] The first terminal 2 may be made of a conductive metal material such as phosphor bronze, and may be formed in a flat plate shape. At one end of the first terminal 2, a mounting hole 2a is fixedly installed at the fixed contact point 3 made of silver tin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com