Method for preventing surface decarbonization of ceramic precision casting die

A technology of precision casting and mould, applied in the field of protection of casting surface quality, can solve the problem of surface decarburization of ceramic precision casting mould

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

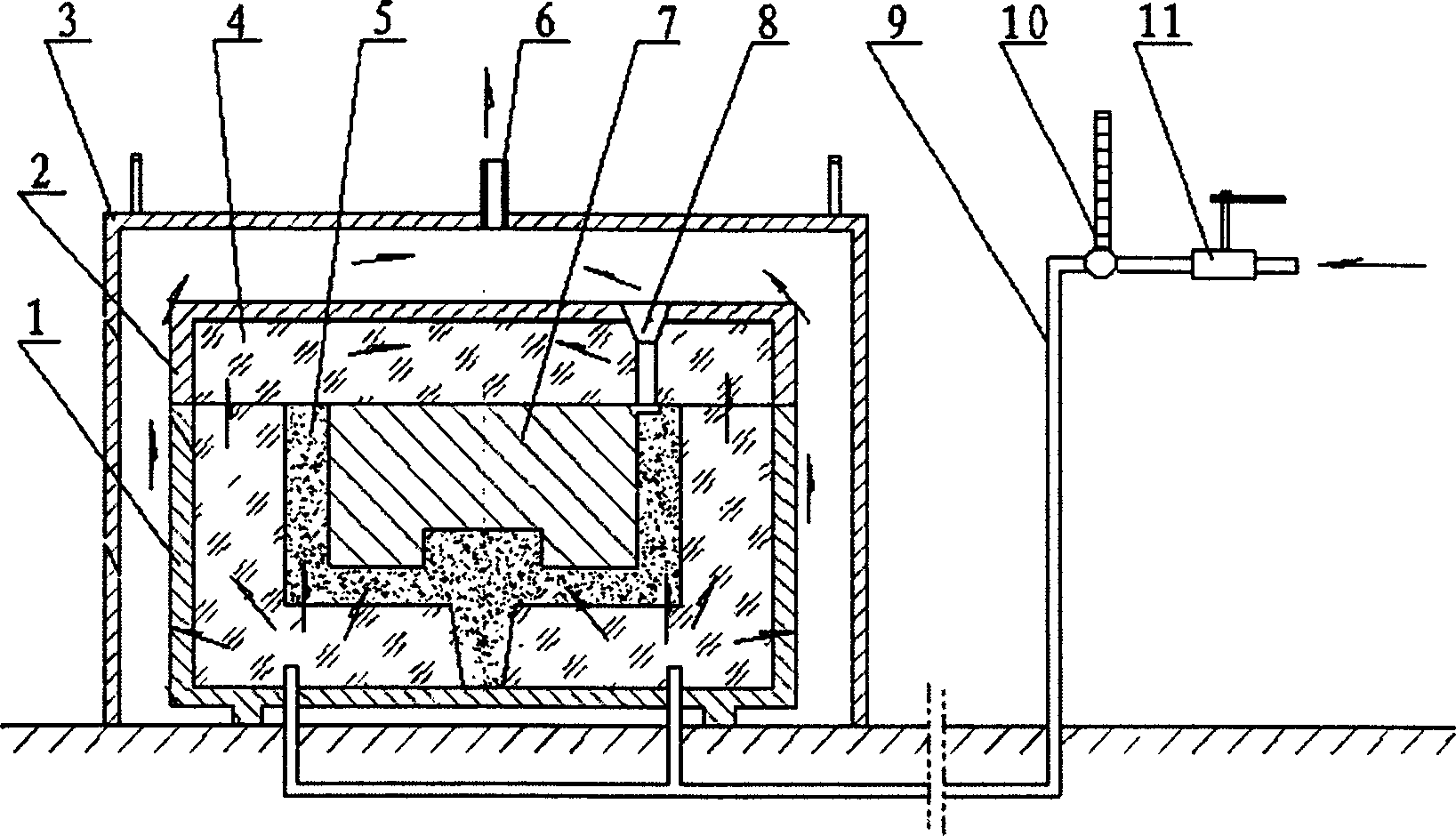

[0018] see figure 1 As shown, the mold shell used in the present invention is a composite ceramic type, the mold cavity is formed by the ceramic type 5, the back cover is a water glass sand cover 4, the upper box 2 and the lower box 1 are combined to form a mold, and the upper box 1 is provided with a pouring mold. Road 8, the heat-resistant protective cover 3 is set outside the mold, and a vent hole 6 is opened above it. One end of the vacuum hose 9 is connected to the water glass sand sleeve 4 from the bottom, and the other end is communicated with the gas source through the flow meter 10 and the valve 11. , the concrete steps of the method of the present embodiment are as follows:

[0019] 1. After the composite ceramic mold is taken out of the 350°C roasting furnace, natural gas is introduced from the bottom into the mold shell through the vacuum hose 9 to drive away the air in the mold shell and cavity and occupy the entire space of the mold shell and cavity When pouring...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap