Breathable laminate permanently conformable to the contours of a wearer

A technology for laminates and wearers, which can be used in layered products, pharmaceutical devices, synthetic resin layered products, etc., and can solve problems such as skin pressure and discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

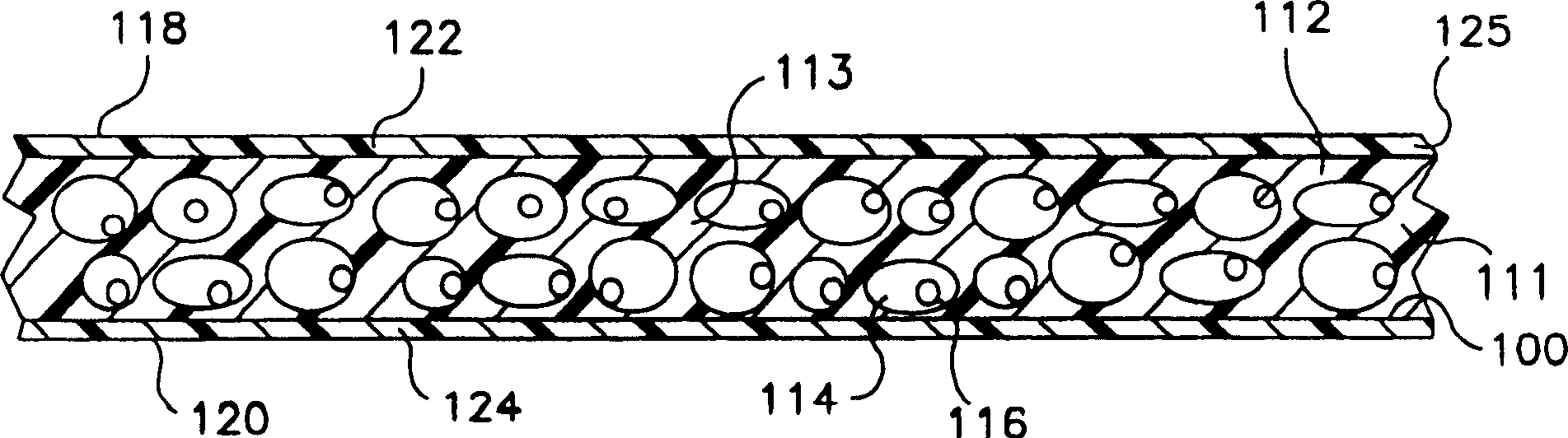

[0178] Several laminates were prepared using three layer A-B-A cast film supplied under the trade designation Huntsman Model 1885 by Huntsman Packaging Company (199 Edison Drive, Washington, Georgia 30763). The core layer of the film comprised 42 wt% linear low density polyethylene and 58 wt% calcium carbonate filler. The film had two skin layers and comprised a mixture comprising: a heterophasic combination of ethylene-vinyl acetate (28% vinyl acetate content), and a propylene-ethylene copolymer called Montell KS-037Pcataloy. The cortex accounts for approximately 3% of the total film thickness.

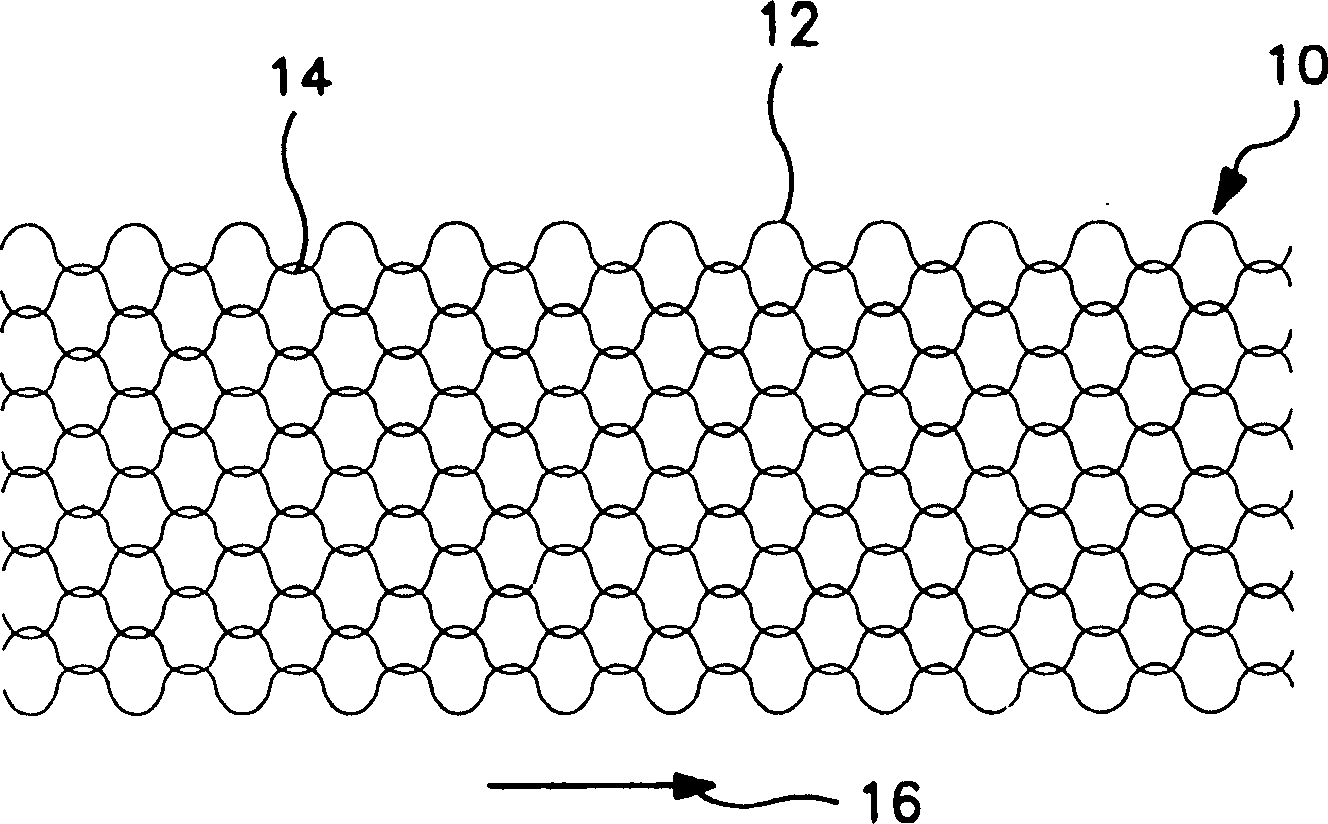

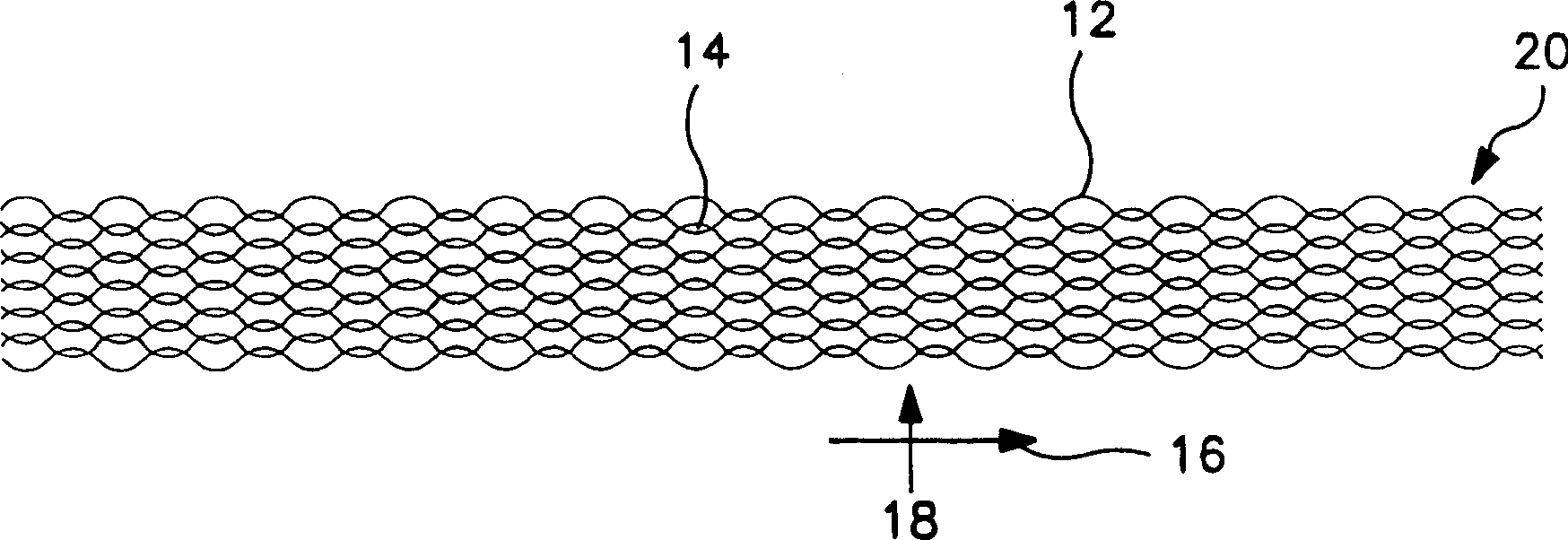

[0179] The film is stretched longitudinally to 3.8 to 4.0 times its original length, thereby producing a WVTR exceeding 2000g / m 2 ·24h breathable microporous film. The breathable film has a basis weight of 19 g / m 2 .

[0180] In the first set of examples (using low-neck spunbond webs), a breathable film of 3 g / m 2 Findley H2525A adhesive, manufactured by Ato Findley (Milwaukee, ...

example 1 and 2

[0188] Examples 1 and 2 (first group)

[0189] Table 1

[0190] As shown above, laminates made using breathable microporous films and low neck-in stretch spunbond materials can be stretched in the cross direction by 25% or 50% of their original width without breaking. After holding the stretched width for 1 min, the laminates in both cases retracted less than 30% of the difference between the stretched width and the original unstretched width.

example 3~6

[0191] Examples 3-6 (second group)

[0192] Table 2

[0193] As shown above, laminates prepared using breathable microporous films and highly necked stretched spunbond webs can be stretched 50%, 100%, 150%, or 200% in the cross direction without breaking. After being held at the stretched width for 1 min, the laminates in all cases retracted less than 30% of the difference between the stretched width and the original unstretched width.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com