Liquid sprayers

A sprayer and liquid technology, applied in the direction of liquid injection devices, injection devices, injection devices, etc., can solve the problems of inability to generate high-speed gas-droplet jets, and achieve the effects of improving fire extinguishing efficiency, reducing energy consumption, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

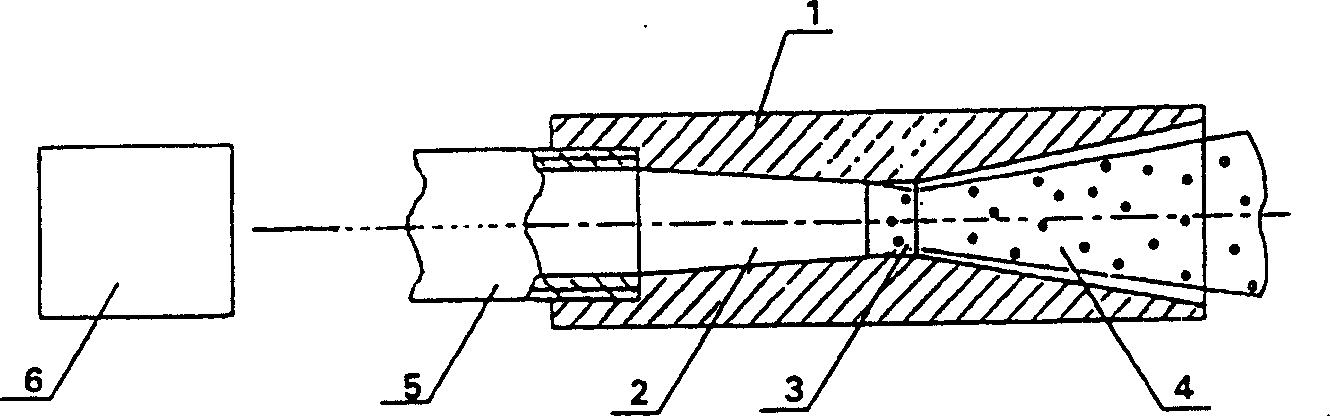

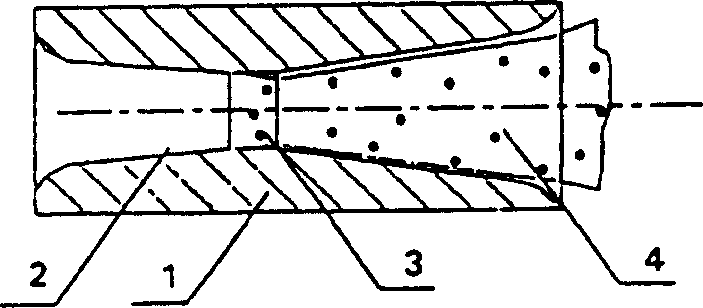

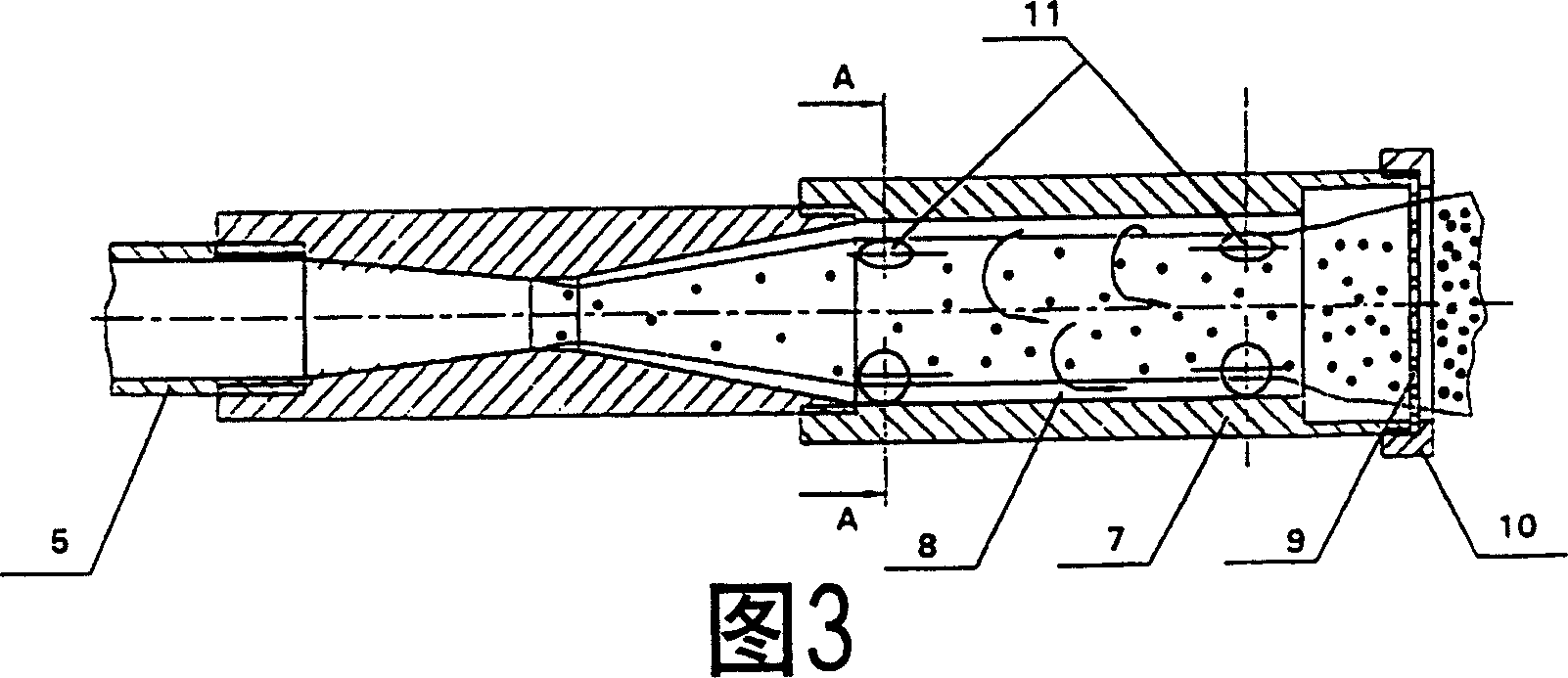

[0036] The liquid sprayer that forms according to first embodiment of the present invention (referring to Figures 1 to 5 ) comprises a housing 1 with a flow channel formed by interconnecting axially aligned parts. An inlet part 2 is made in the form of a shrink tube having an outlet connected to the inlet of the cylindrical part 3 . An outlet section 4 made in the form of a conical diffuser comprises an inlet connected to an outlet of the cylindrical section 3 . The length of the cylindrical portion is 0.7 times its diameter. One cone defining the shrink tube had an apex angle of 13° and one cone defining the diffuser had an apex angle of 20°.

[0037] The housing 1 is connected on the inlet side of the shrink tube to a pipe connection 5 of the line of a liquid supply system. The liquid supply system includes a pump or pressure type liquid booster 6 .

[0038] In a preferred embodiment (see figure 2 ), the inlet edge of the constriction tube that determines the flow cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com