System forming,filling and sealing flexible bags

A flexible plastic, injection-type technology, applied in the field of systems, can solve problems such as incomplete disinfection, ineffectiveness, and the influence of correct selection of disinfection solution doses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

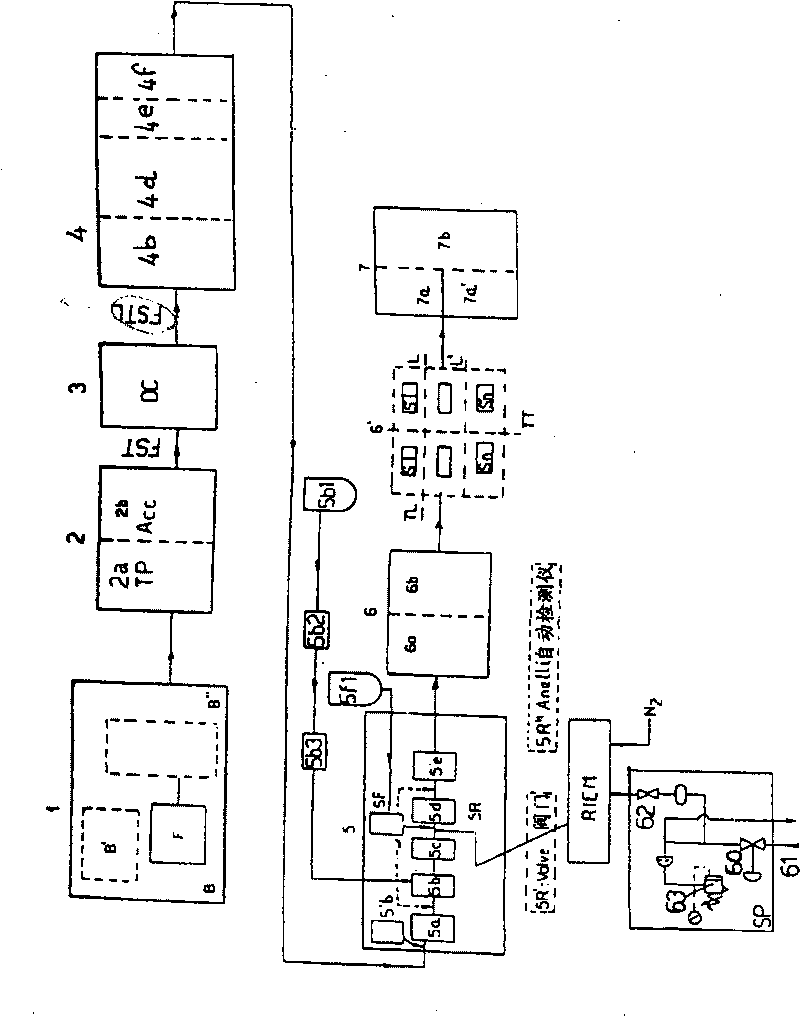

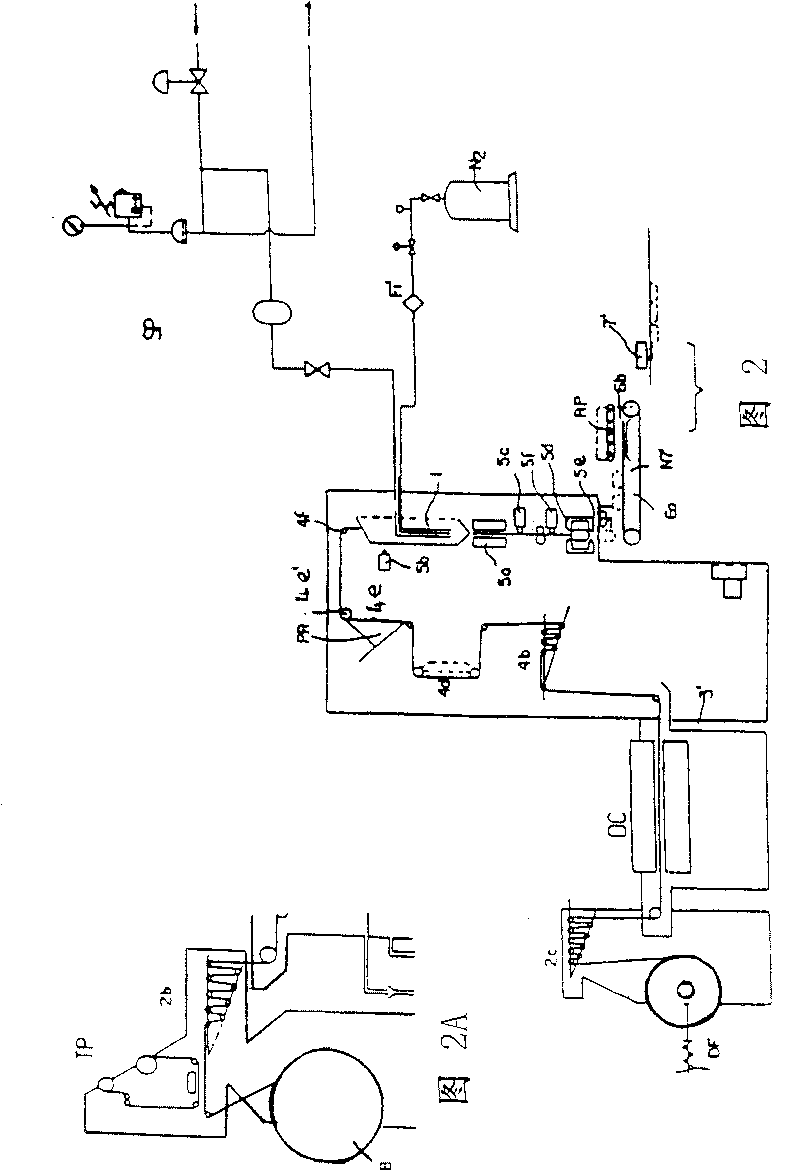

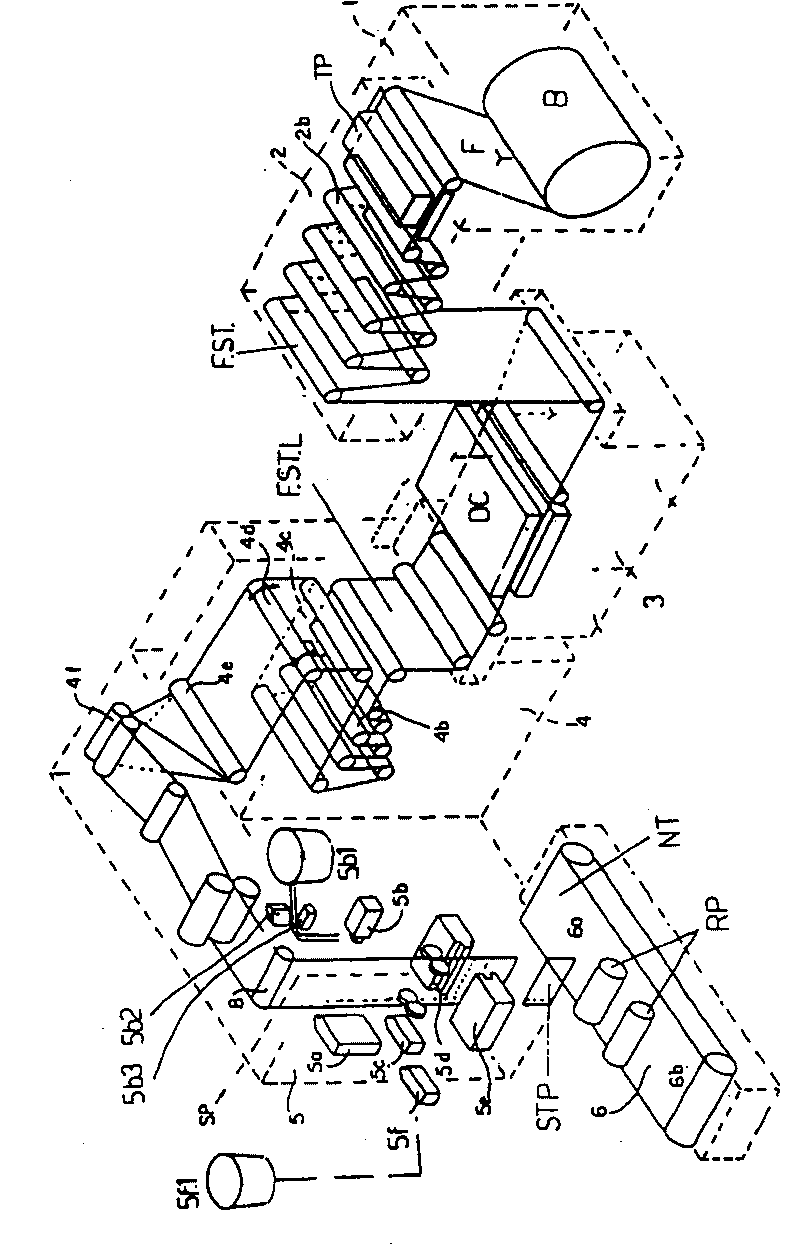

[0033] figure 1 and 2 The system of the invention is shown, comprising at least 5 stations, where each station is involved in one or more steps of the method of the invention.

[0034] refer to figure 1 , Box 1 represents the supply station, which provides the film F from the first roll B. Dotted rectangular boxes B' and B" represent alternative roll configurations. Roll B' can be placed outside and parallel to the first roll B. Preferably, roll B' has the same Width. Alternatively, Roll B" may be substituted for Roll B or B'. In this case, the roll B" is preferably N times the width of B or B'. Refer to figure 2 , and the material roll B and / or B', or B "is associated with the tension adjustment braking device DF.

[0035] figure 1 Box 2 in , represents full printing station (TP) 2a, followed by stacking station 2b. Full printing station 2a provides in-line printing of films. The accumulation station 2b deposits the printed film in line with the full printing station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com