Automatic pressure adjustment tyre of automobile

An automatic pressure regulation and automobile technology, applied in the direction of wheels, tire measurement, high elastic wheels, etc., can solve problems such as deviation, tire blowout braking distance, easy tail flicking, etc., to reduce tire pressure, solve easy out of control and blowout tires , the effect of increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

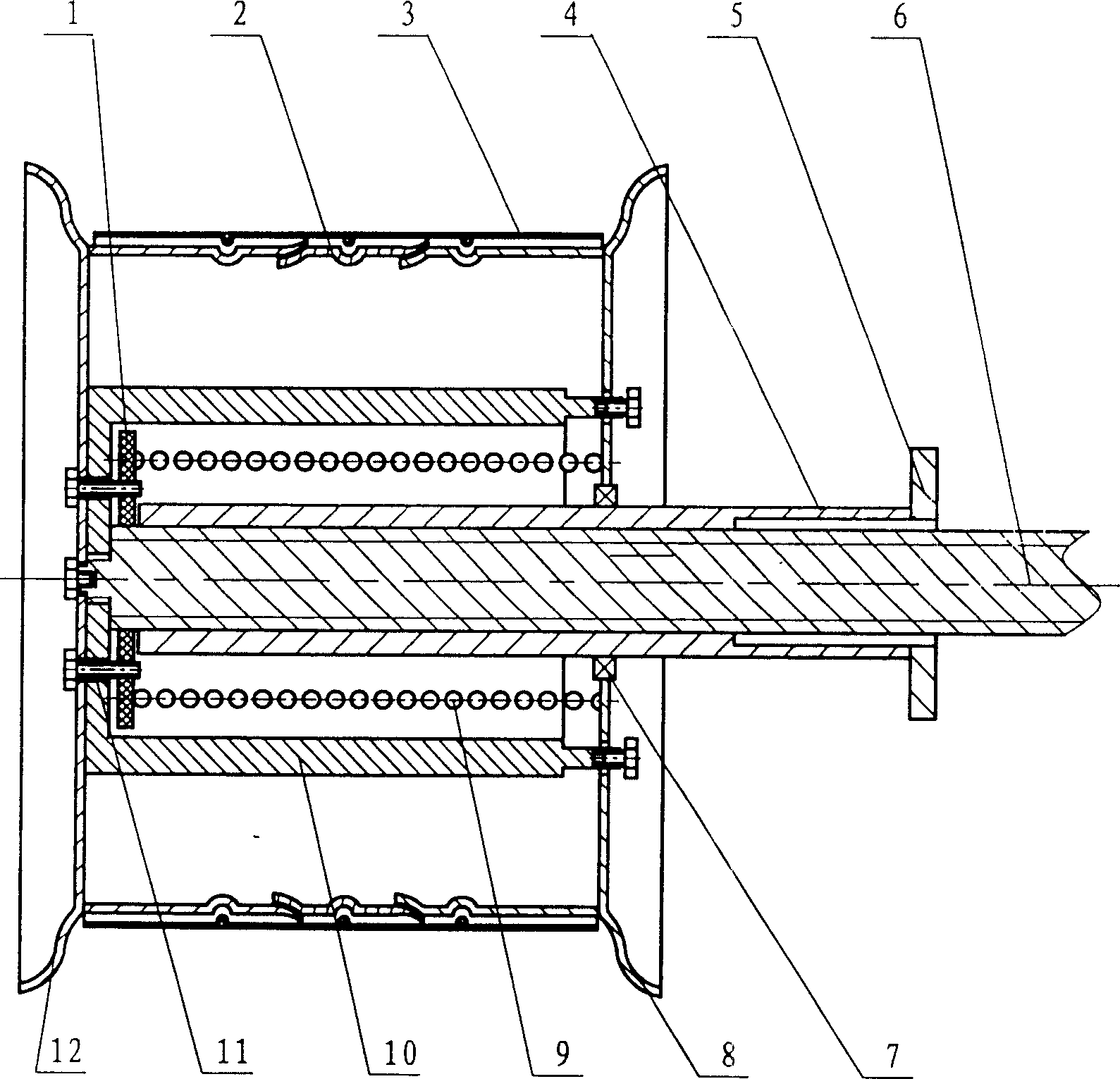

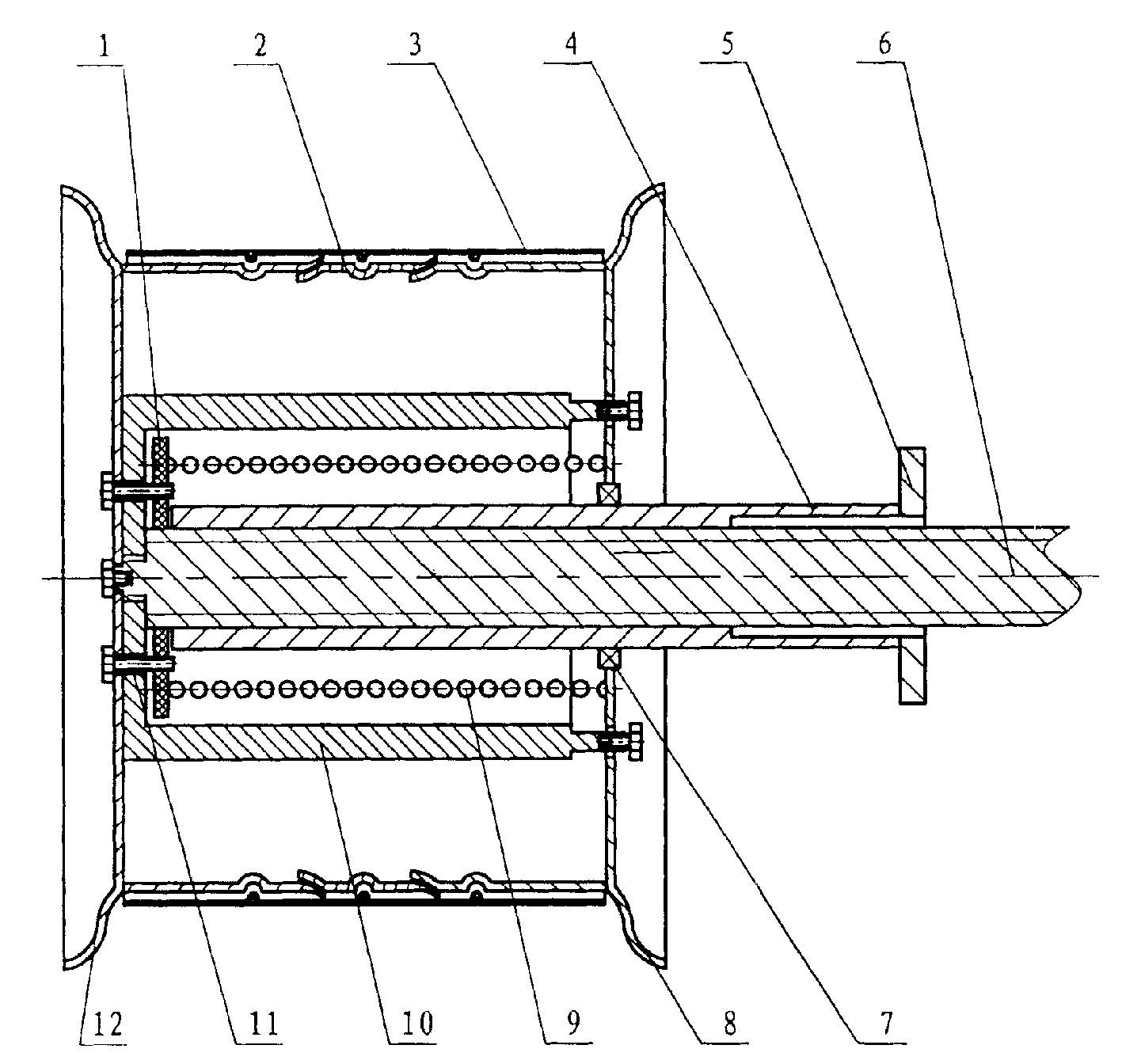

[0010] Further explanation is given below in conjunction with accompanying drawings:

[0011] Such as figure 1 As shown, an automobile automatic pressure regulating tire of the present invention includes an outer hub body 12, an inner hub body 8, an elastic metal ring 2, the middle of the outer hub 12 is connected with the automobile drive shaft 6, and the outer hub body 12 and the inner hub body 8 There is a movable connection with the elastic metal ring 2, the outer hub body 12 and the inner hub body 8 are provided with a sealing tape 3 outside the elastic metal ring 2, the outer hub body 12 is provided with a sleeve 10, and the middle of the bottom of the sleeve 10 is provided with a flower The keyway, the sleeve 10 is provided with an adjustment disc 1, the adjustment disc 1 is provided with an adjustment screw 11 and a spring 9, the other end of the spring 9 is connected to the inner hub body 8, and the drive shaft 6 is provided with a spline at the bottom of the sleeve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com