Hair brush work bench with interchangeable bayonet

A workbench and brush technology, which is applied in the field of brush work platforms, can solve the problems that brushes cannot be produced on the same brush workbench, high-efficiency production cannot be achieved, and the time required for swinging angles is long, so as to achieve the required saving Time, convenient replacement, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

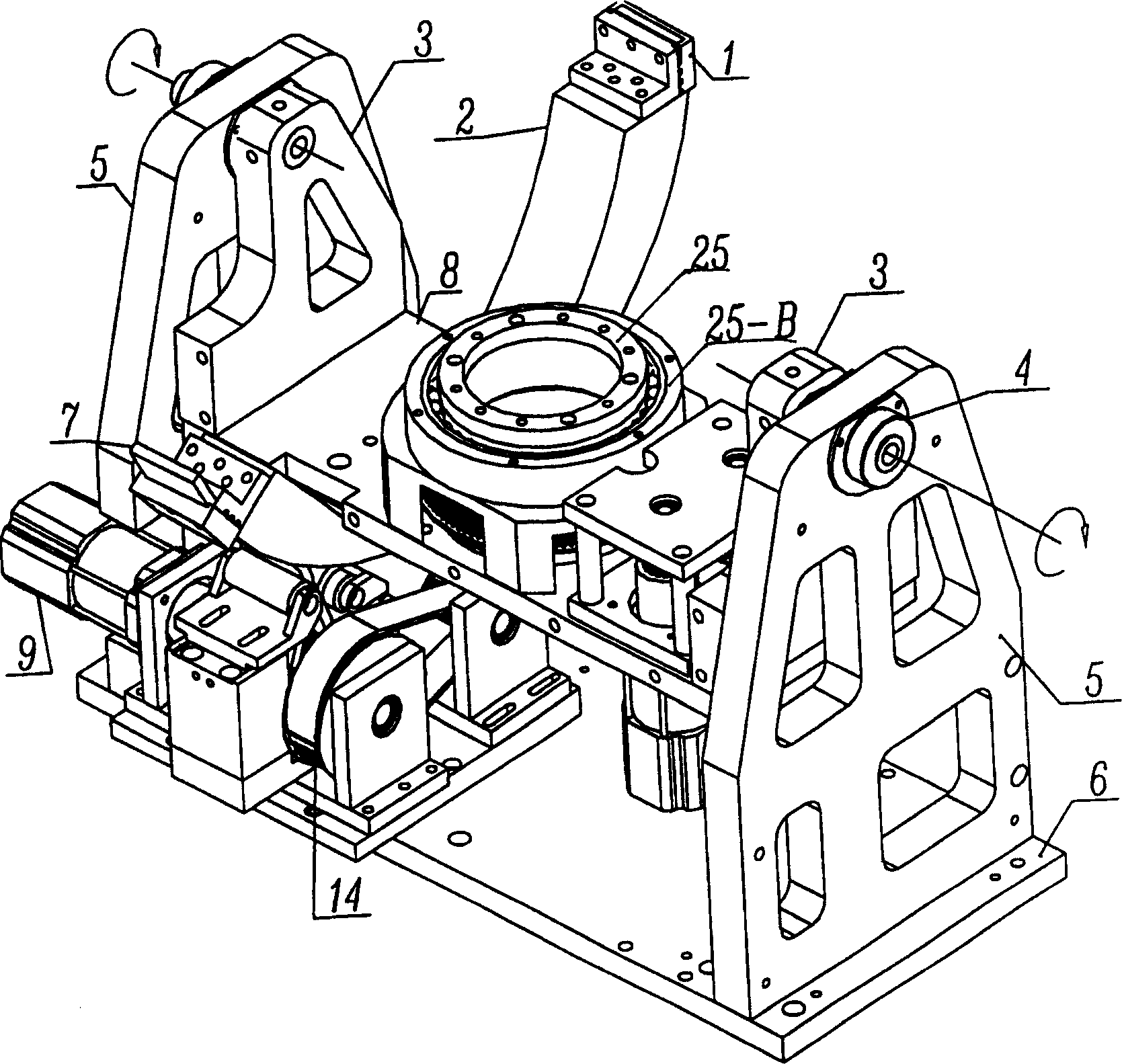

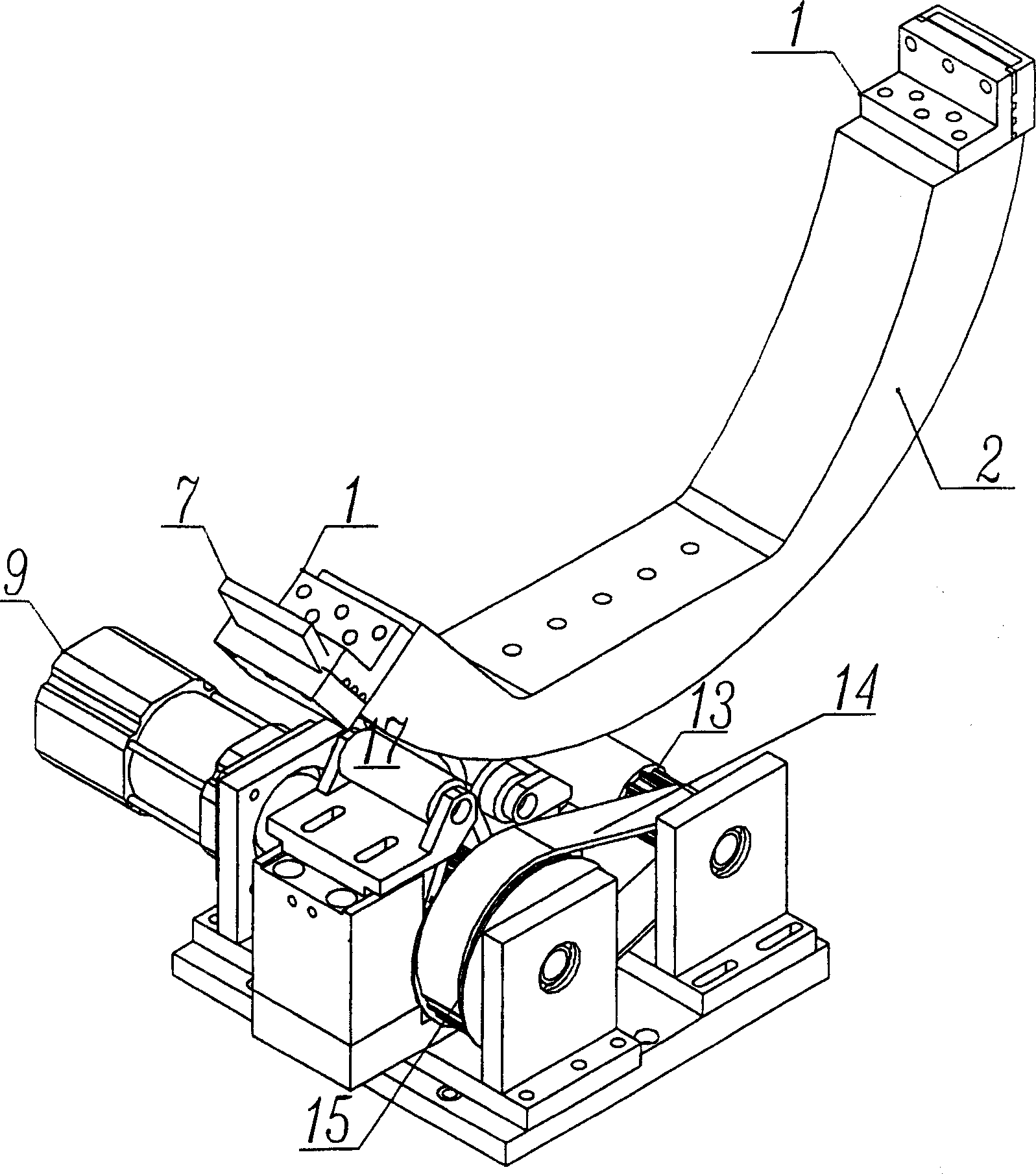

[0025] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention.

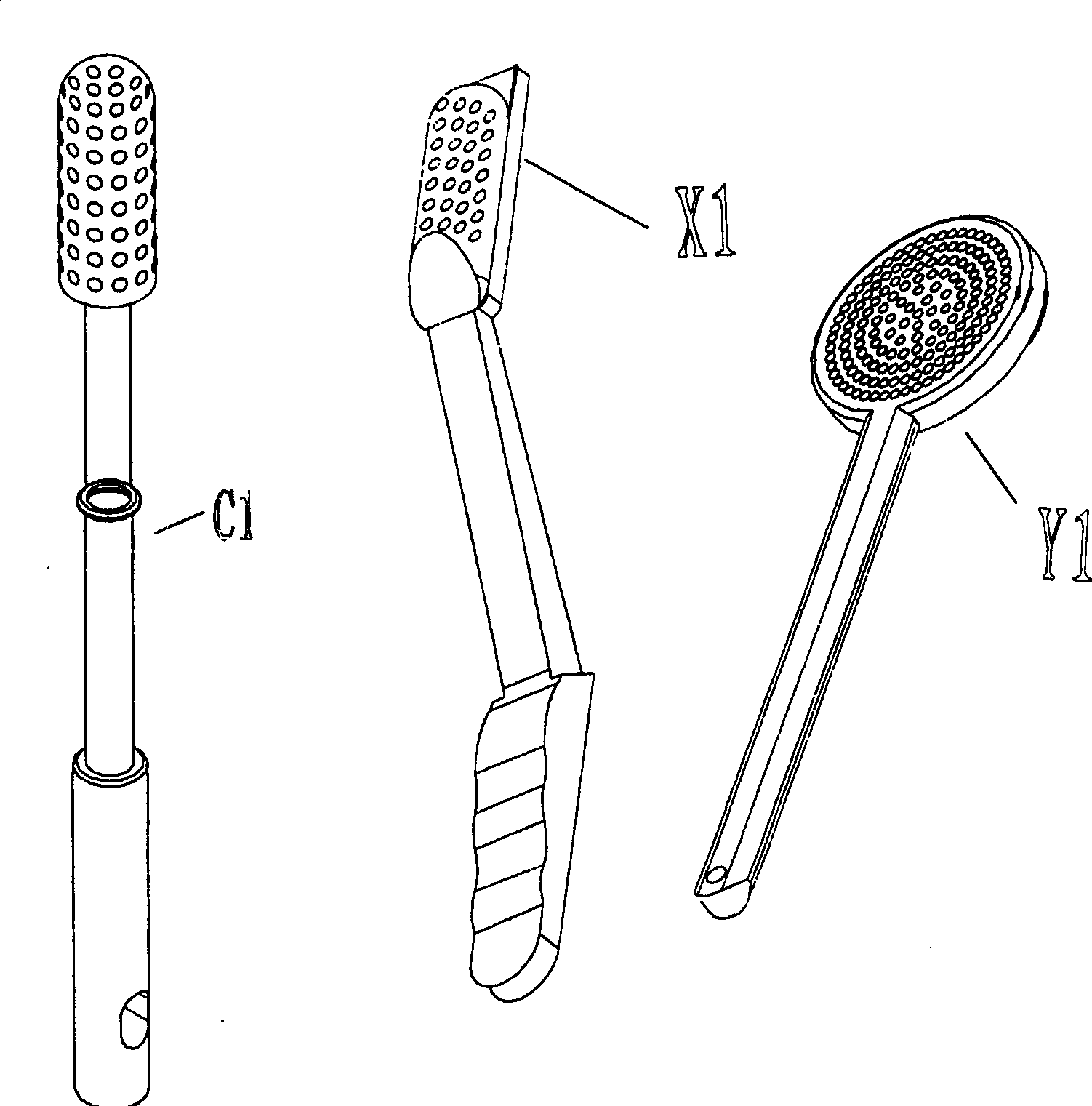

[0026] In the figure, 1 is a belt clip, 2 is a swing arm, 3 is a connecting plate, 4 is a rotating shaft, 5 is a bracket, 6 is a bottom plate, 7 is a synchronous belt, 8 is a panel, 9 is a motor I, 10 is a pulley I, 11 is belt I, 12 is pulley II, 13 is pulley III, 14 is belt II, 15 is pulley IV, 16 is pulley V, 17 is belt pressing block, 18 is motor II, 19 is pulley A, 20 is belt A, 21 is belt pulley B, 22 is belt pulley C, 23 is belt B, 24 is belt pulley D, 25 is the main shaft of rotating shaft, 25-B is the bearing sleeve of rotating shaft, 26 is the socket of washing pot brush, 27 is the socket of toilet brush, 28 is a circular brush socket; X1 is the handle of the pot washing brush, X2 is the jaw of the pot washing brush, X3 is the pin shaft, X4 is the spring, X5 is the transi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com