Garbage furnace

A waste incinerator and grate technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as insufficient waste incineration, reduced waste incineration efficiency, waste burning dead corners, etc., and achieve the effect of full combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

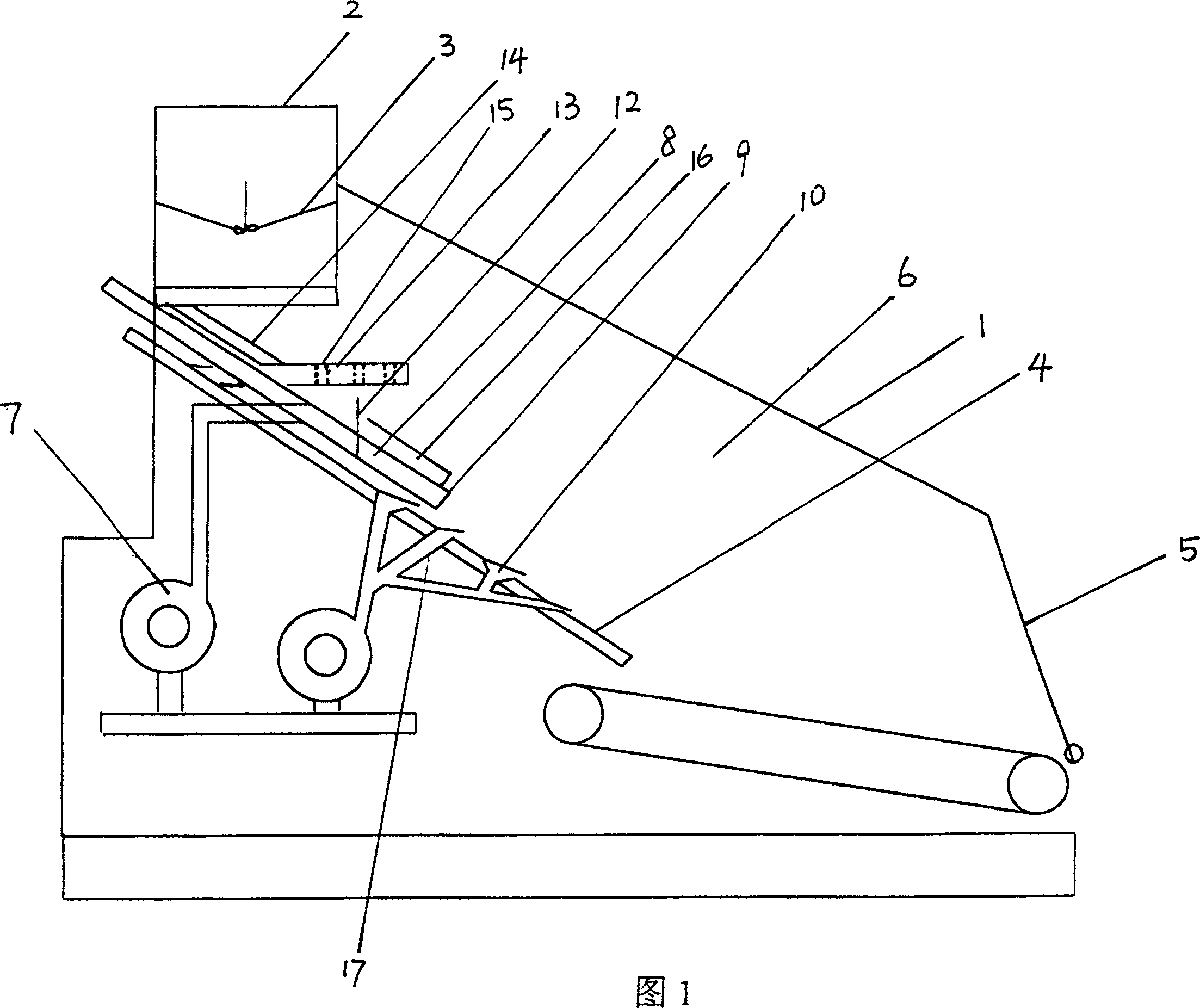

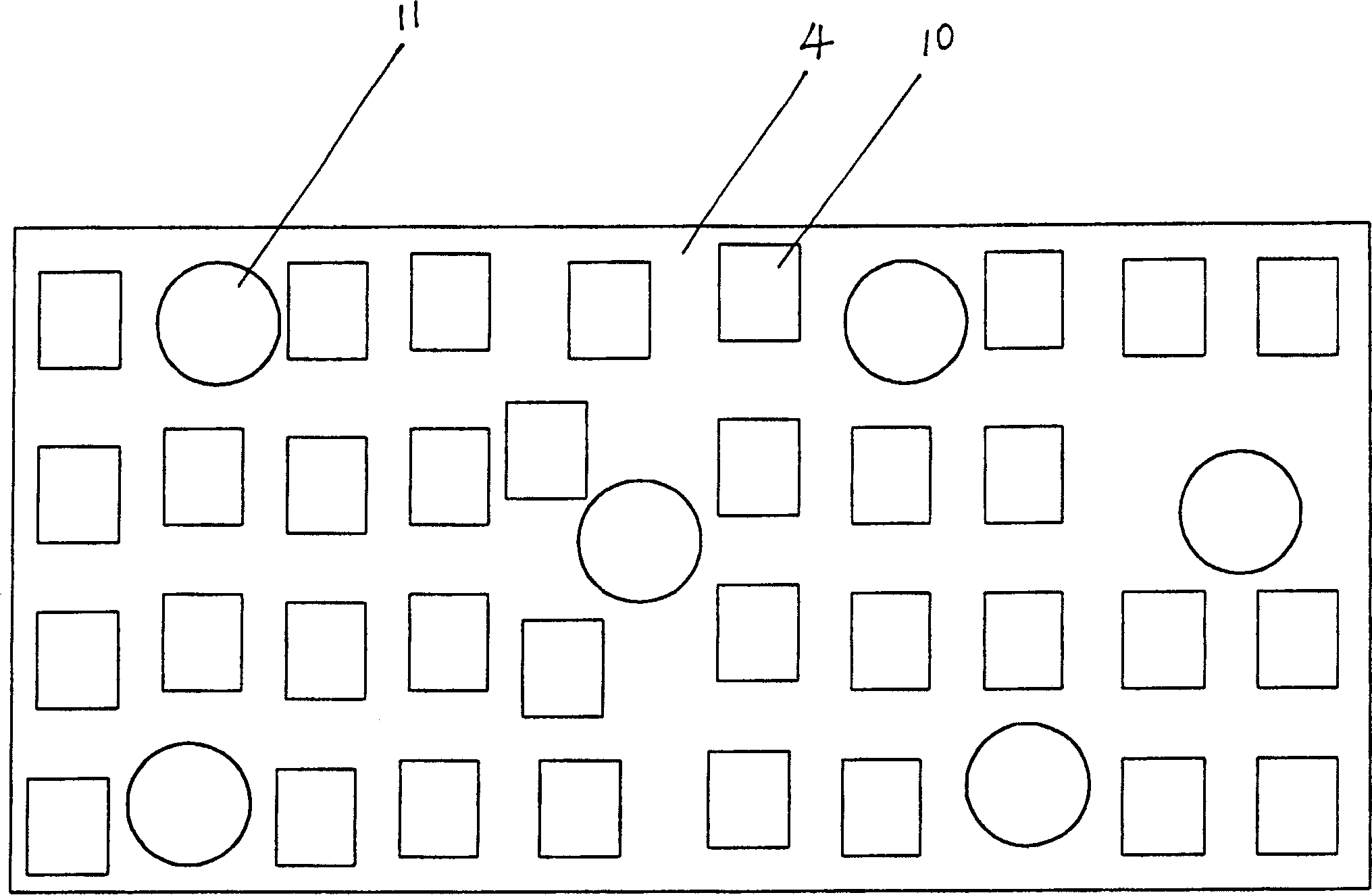

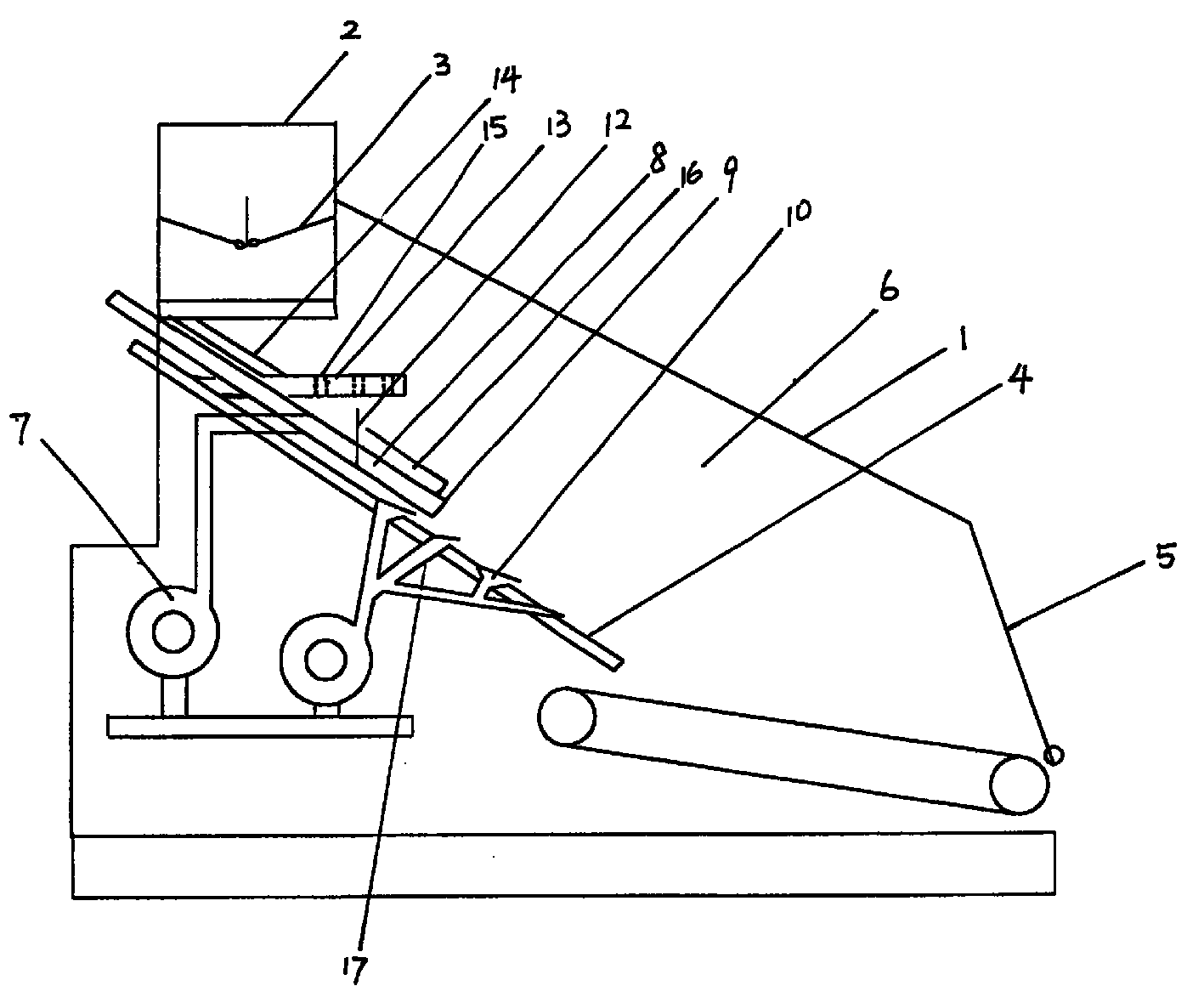

[0017] Figure 1, figure 2 As shown, the garbage incinerator of the present invention includes a body of furnace 1, a feed inlet 2, a movable material door 3, a fire grate 4, a slag outlet 5, a furnace 6, a push plate 12, an air supply system, and the air supply system includes a blower fan 7 and the main air duct 8, which is characterized in that: the main air duct 8 is arranged along the fire grate 4, its outlet 9 is located above the middle of the fire grate 4, and the fire grate 4 is provided with auxiliary air ducts 10 all over.

[0018] The fire grate 4 is a chain-type fire grate, and the auxiliary air duct 10 is a plurality of through holes arranged on the chain-type fire grate or is designed as a duckbill air duct (that is, a through-hole air duct) in order to prevent the auxiliary air duct from being blocked by garbage. raised).

[0019] The fire grate 4 can also be adopted as a plate fire grate, and the auxiliary air duct 10 is a plurality of through holes or duckbil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com