Straightener for 3D round bar with multiple skew rollers

A straightening machine and oblique roller technology, which is applied in the field of three-dimensional multi-oblique roller round bar straightening machine, can solve the problems of no further proposal, and achieve the effect of reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

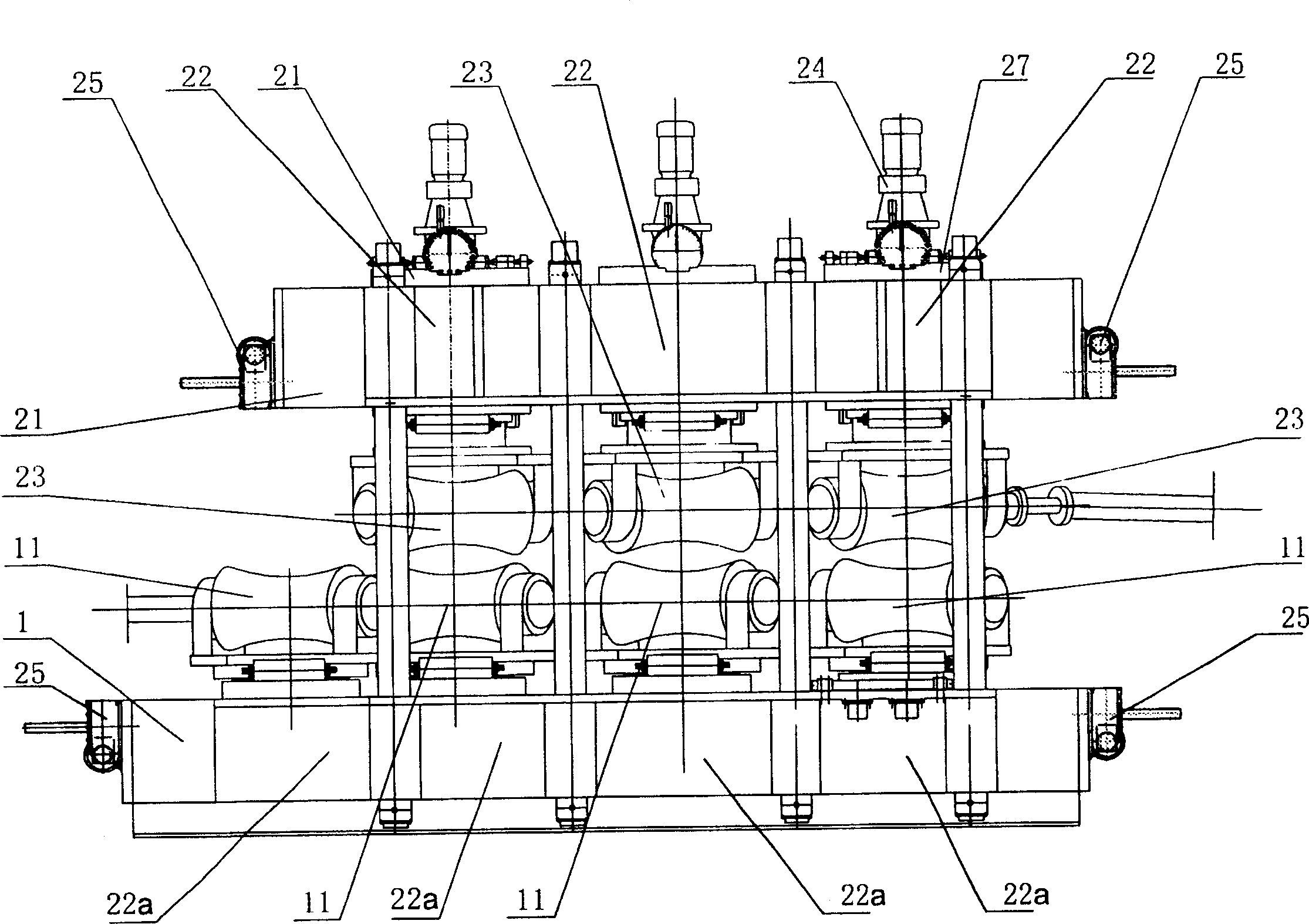

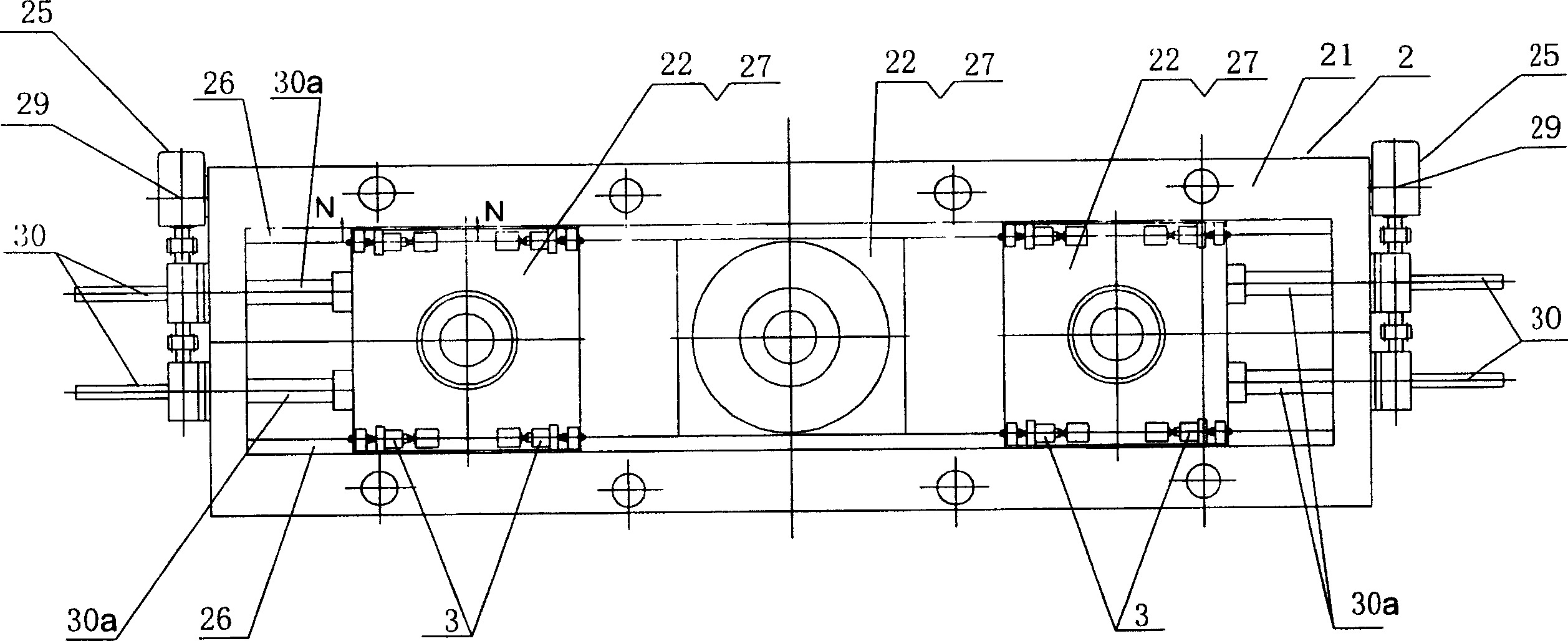

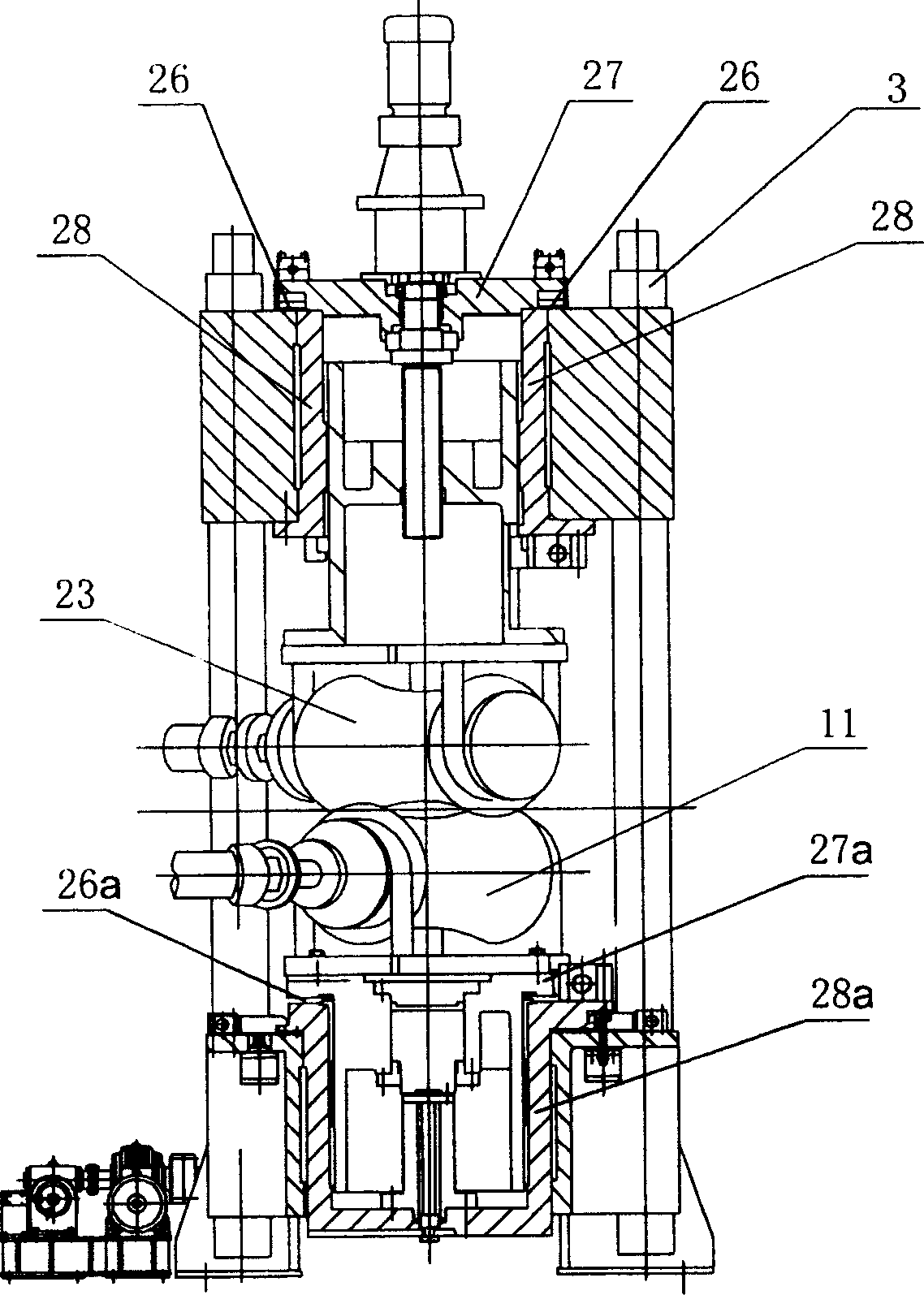

[0014] The present invention as figure 1 , figure 2 , image 3 , Figure 5 As shown, a three-dimensional multi-slant roller round material straightening machine includes a frame and an upper beam, a lower beam and a column arranged on the frame, and the upper and lower beams include upper and lower beam frames 21, 1 And some roller bases 22,22a and the transmission device 25 assembled on the upper and lower beam frames 21,1; said upper and lower roll bases 22,22a and the upper and lower beam frames 21,1 are respectively provided with corresponding devices on the upper , the oblique type straightening roller group consisting of some straightening rollers 11,23 on the lower beam frame 21,1 and each roller stand 22,22a up and down; each upper roller stand 22 is provided with the upper roller stand 22 The straightening roller 23 provided on the top is a transmission mechanism 24 for vertical displacement relative to the upper cross beam frame 21; The straightening rollers 23,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com