A strategy method for pressure straightening of metal profiles

A metal profile and straightening technology, which is applied in metal processing, metal processing equipment, forming tools, etc., can solve the problem of inability to effectively control the local straightness of the profile, and achieve the improvement of straightening efficiency, difficult to guarantee accuracy, and high labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

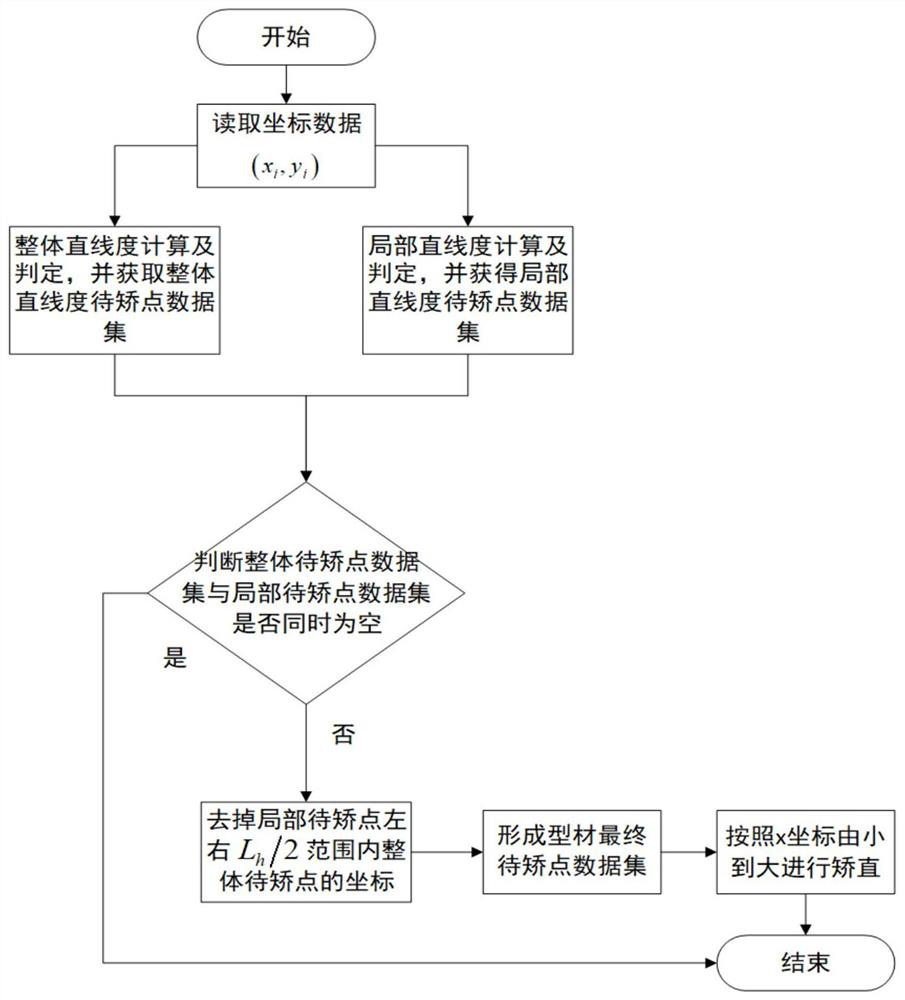

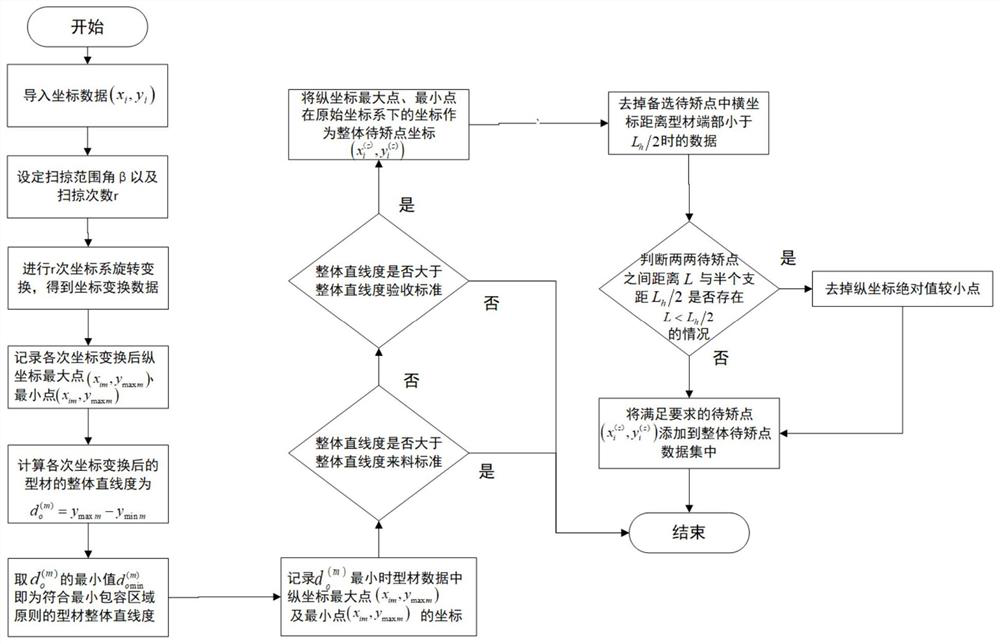

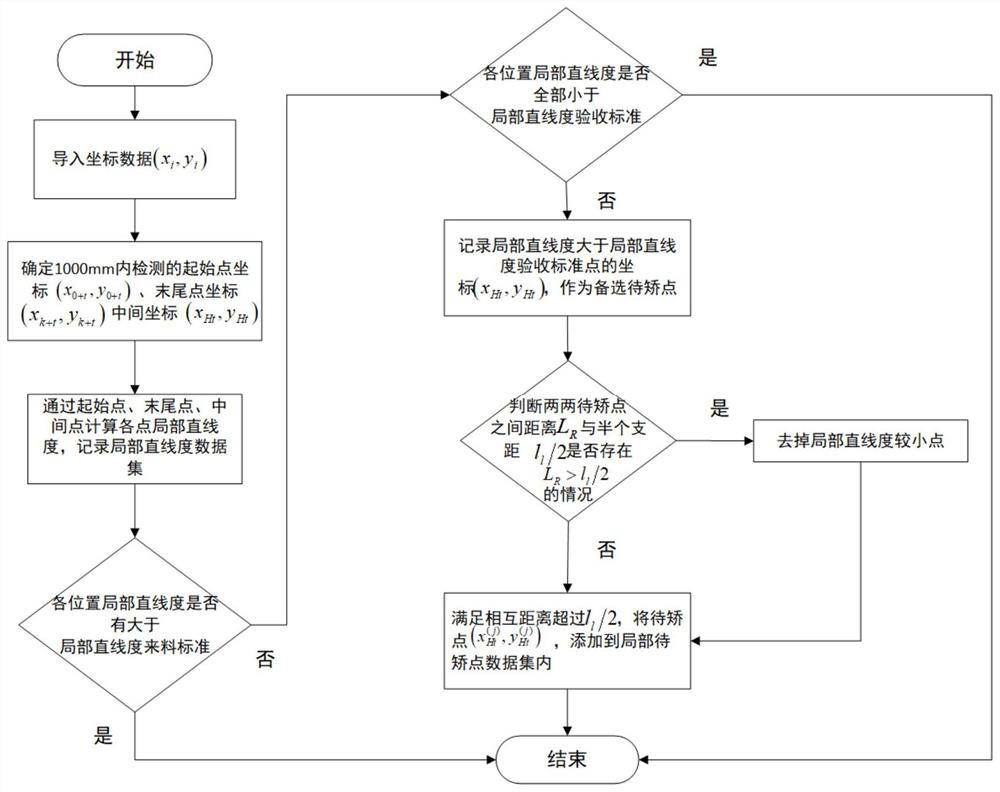

Method used

Image

Examples

Embodiment

[0076] The geometric dimensions of the square thick-walled pipe fittings are 8000mm in total length, 14mm in wall thickness, and 80mm×80mm in section size. Feed the pipe to the table top of the straightening machine, and the straightness detection device detects the upper surface of the pipe from left to right. Set the first detection point on the left as the coordinate point O(0, 0), and cross the point to be parallel to the The straight line of the table top of the leveler is the x-axis, and the line perpendicular to the table top of the leveler is the y-axis, and the original plane rectangular coordinate system is established. The straightness detection device is spaced at a fixed distance of 20mm along the pipe to detect and obtain the coordinate data of each position on the upper surface of the profile (x i ,y i ), i=1,2,...,401.

[0077] First, calculate and determine the overall straightness:

[0078] The overall straightness of the profile is determined according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com