Cage rolling machine

A rolling cage machine and rolling cage technology, applied in the field of rolling cage machine, can solve the problems of low stirrup efficiency and poor stirrup effect, and achieve the effects of improving quality, facilitating guidance, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

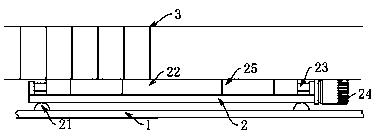

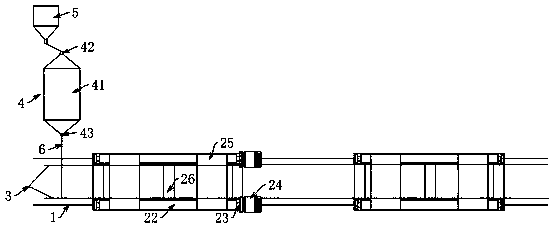

[0028] Such as Figure 1-4 As shown, the rolling cage machine includes a moving device for carrying the steel cage skeleton and driving it to walk and a wire-releasing device for straightening the winding ribs 6. The moving device includes a guide rail 1 and a channel steel support 2, and the channel steel support 2 The pulley 21 installed at its lower end moves along the guide rail 1, and the two sides of the channel steel bracket 2 are provided with rollers 22 in parallel. A structure in which the steel cage skeleton is driven to rotate by the roller 22;

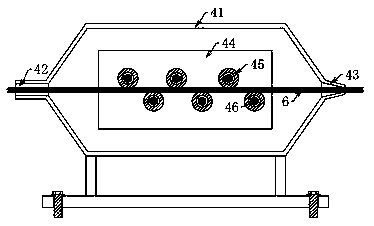

[0029] The pay-off device includes a wire guide 5 for guiding the coiled winding ribs 6 and a straightening machine 4 for straightening the winding ribs 6, and the winding ribs 6 are spirally wound through the wire guides 5 and the straightening machine 4 in turn. The structure outside the steel cage skeleton on the channel steel support 2.

[0030] The two drums 22 are connected by a transmission belt 25. There can be t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com