Valve plate rod straightening device

A straightening device and valve disc technology, applied in the field of valve production devices, can solve the problems of waste of financial resources and high rework rate, and achieve the effect of ensuring the straightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

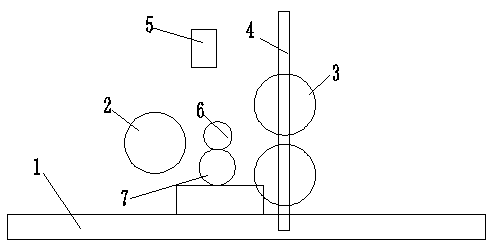

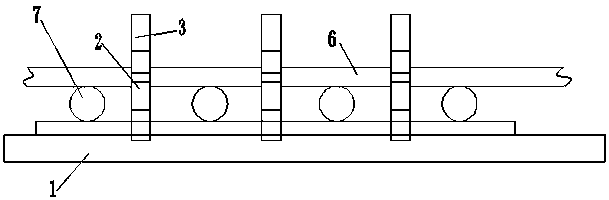

[0015] A valve disc rod straightening device, the straightening device includes a workbench 1, a roller 2 is arranged on one side of the workbench 1, and a roller 2 3 is arranged on the other side of the workbench 1;

[0016] The first roller 2 and the second roller 3 perform rotational movement, the first roller 2 is fixed in the horizontal direction and is arranged in one group, and the second roller 3 is two groups and can move horizontally;

[0017] Two groups of rollers 3 are arranged up and down, and the position of said roller one 2 in the longitudinal direction is in the middle of the longitudinal position of two groups of rollers 3 .

[0018] The two groups of rollers 3 are connected to the elevating rod 4 by a lifting device, and a controller is provided to control the two groups of rollers 3 to realize synchronous movement on the elevating rod 4, and the two groups of rollers 3 move in opposite directions on the elevating rod 4 .

[0019] A lubricating oil spraying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com