Push-button switch

A button and switch technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problem of noisy reset sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

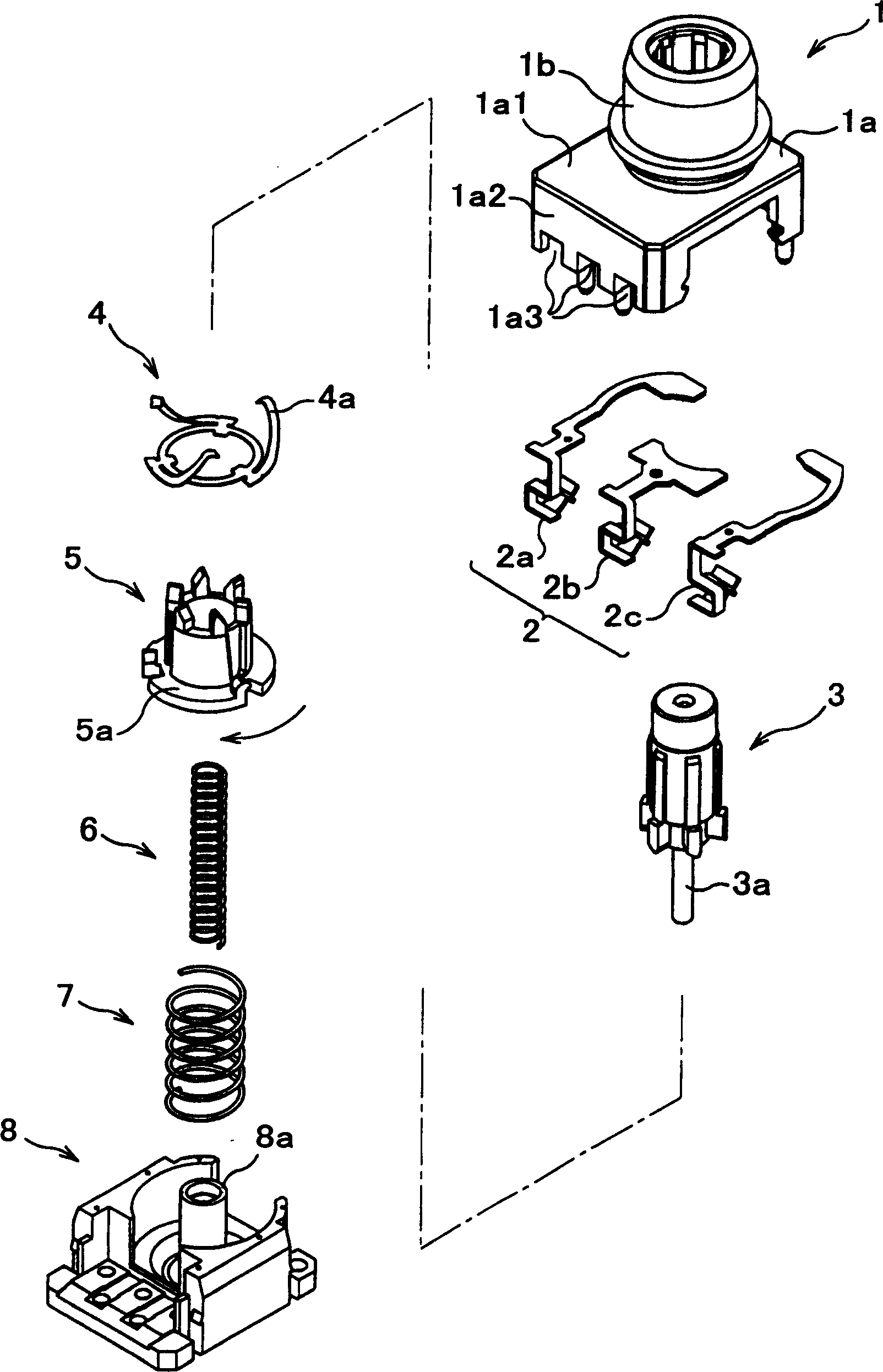

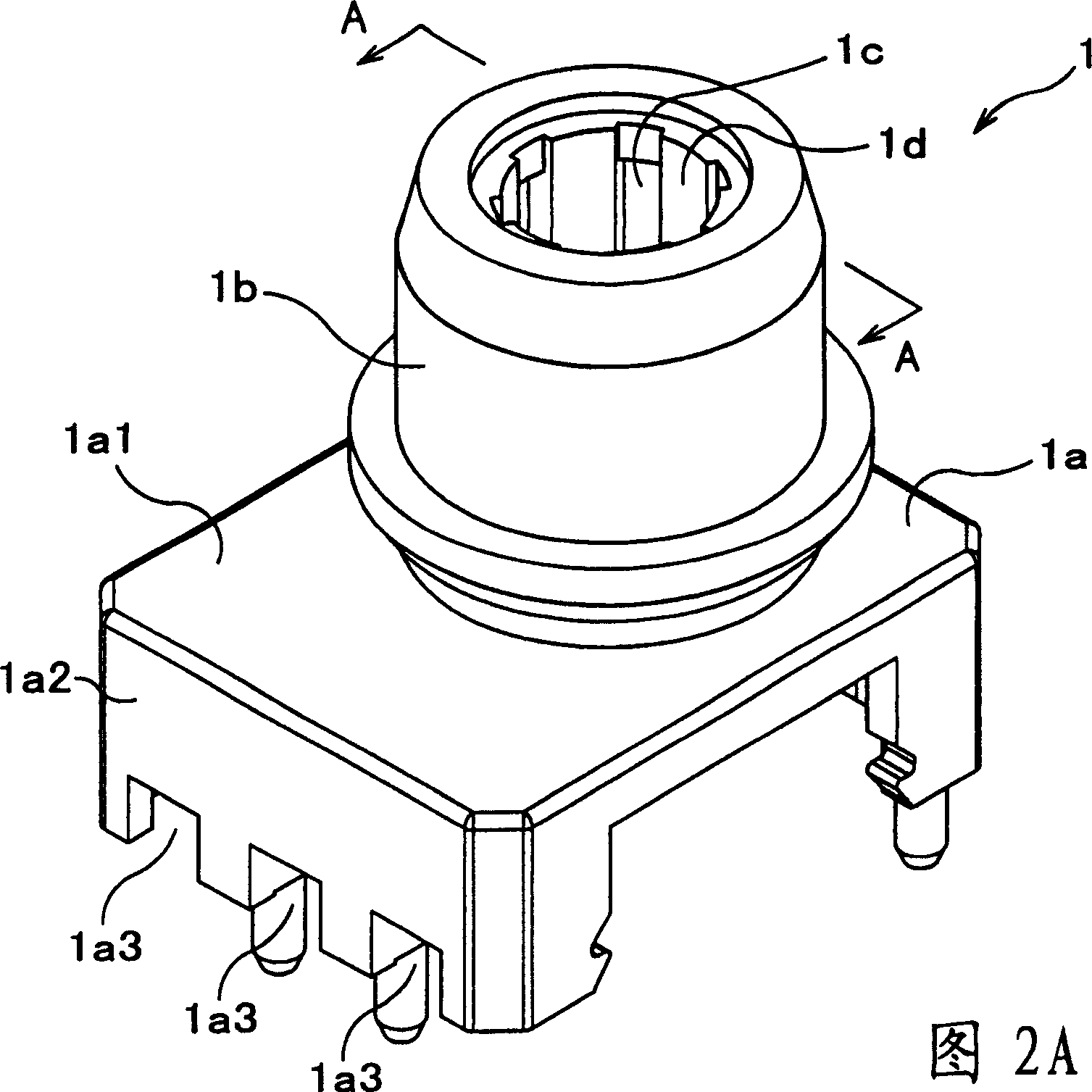

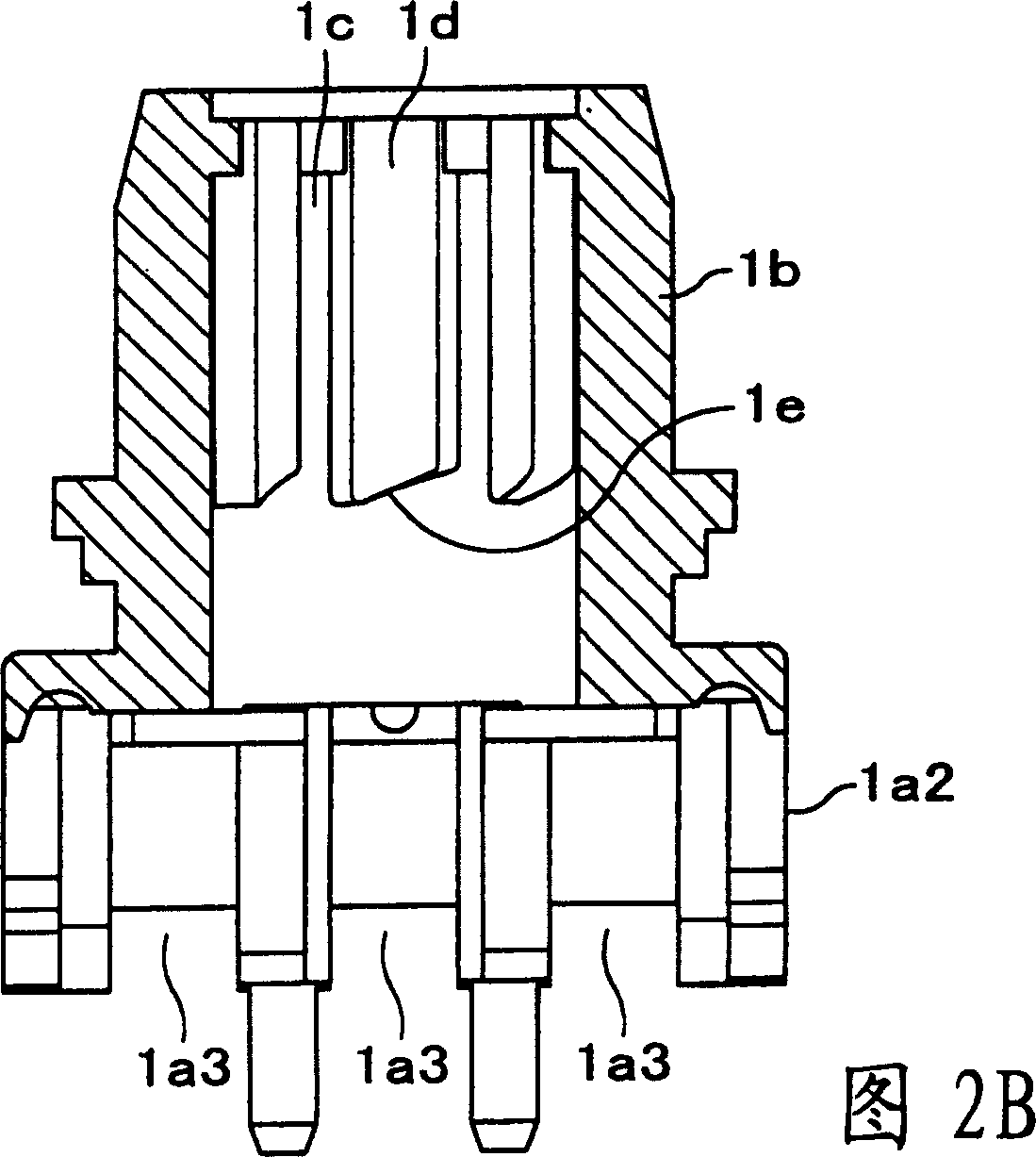

[0085] The following will refer to figure 1 The push button switch in the first embodiment of the present invention will be described. The push button switch according to this embodiment includes:

[0086] A substantially square housing 1a; an upper housing 1 having a substantially cylindrical cylindrical portion 1b disposed in said housing 1a; three stationary terminals 2a, 2b, 2c, which The stationary terminal is made of conductive material, and is in contact with a contact portion 4 to be mentioned below; a button 3, which is approximately cylindrical and is adapted to be installed in the cylindrical portion 1b so as to be able to move along the cylindrical portion 1b. The inner surface of 1b slides in the vertical direction, and a guide rod 3a extends from the bottom of the button; a contact part 4, which is made of conductive material and is generally flat ring-shaped, and the contact part 4 is made of The flange 5a of the rotor 5 to be mentioned below is locked, and t...

no. 2 example

[0142] The following will refer to Figure 13 to Figure 1 5 to describe the push button switch in the second embodiment of the present invention in detail. Such as Figure 13 As shown, the structure of the push button switch in this embodiment is similar to that of the first example, however, the difference lies in the stationary terminals 2a, 2b, 2c connected to the wires 9a, 9b, 9c. Such as Figure 14A As shown, the stationary terminals 2a, 2b, 2c include flat surface portions 2a1, 2b1, 2c1 similar to the first embodiment, and these stationary terminals are connected to the arms 4a ( Figure 5A , 5B, 5C) and the cable clamping mouth 2a2, 2b2, 2c2 are in contact, and the wires 9a, 9b, 9c are fixed to the said cable clamping mouth. As shown in Fig. 14B and Fig. 14C, the core wire 9a2, 9b2, 9c2 protruding from the end of the insulating shell 9a1, 9b1, 9c1 of the wire is compressed through the cable clamping port 2a2, 2b2, 2c2, and is connected with the cable The clamping op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com