Method for preventing chip repetition deposition

A wafer reset technology, applied in instruments, electrical digital data processing, electrical components, etc., can solve problems such as wafer scrapping, repeated deposition, and poor contact of cassettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

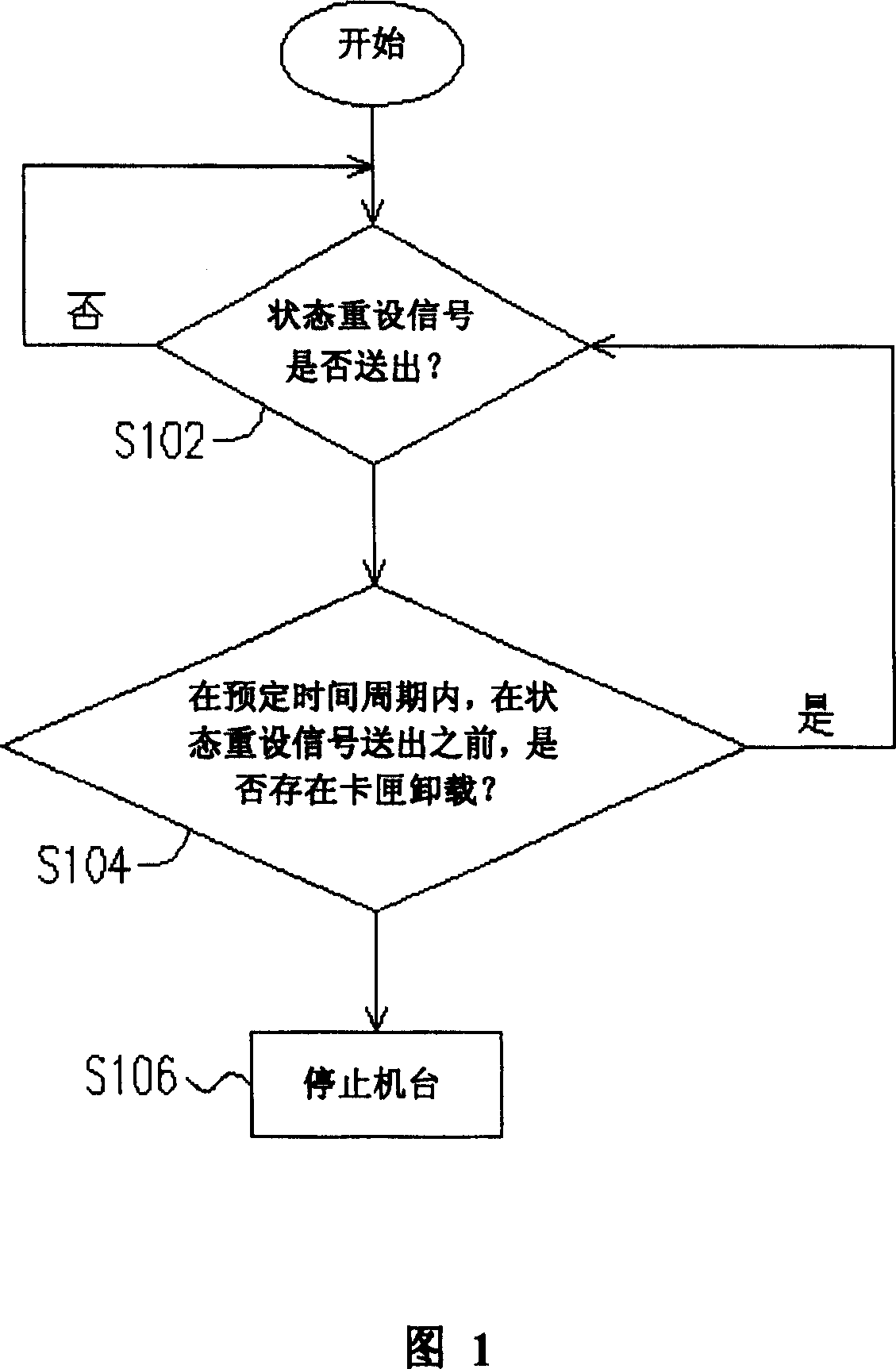

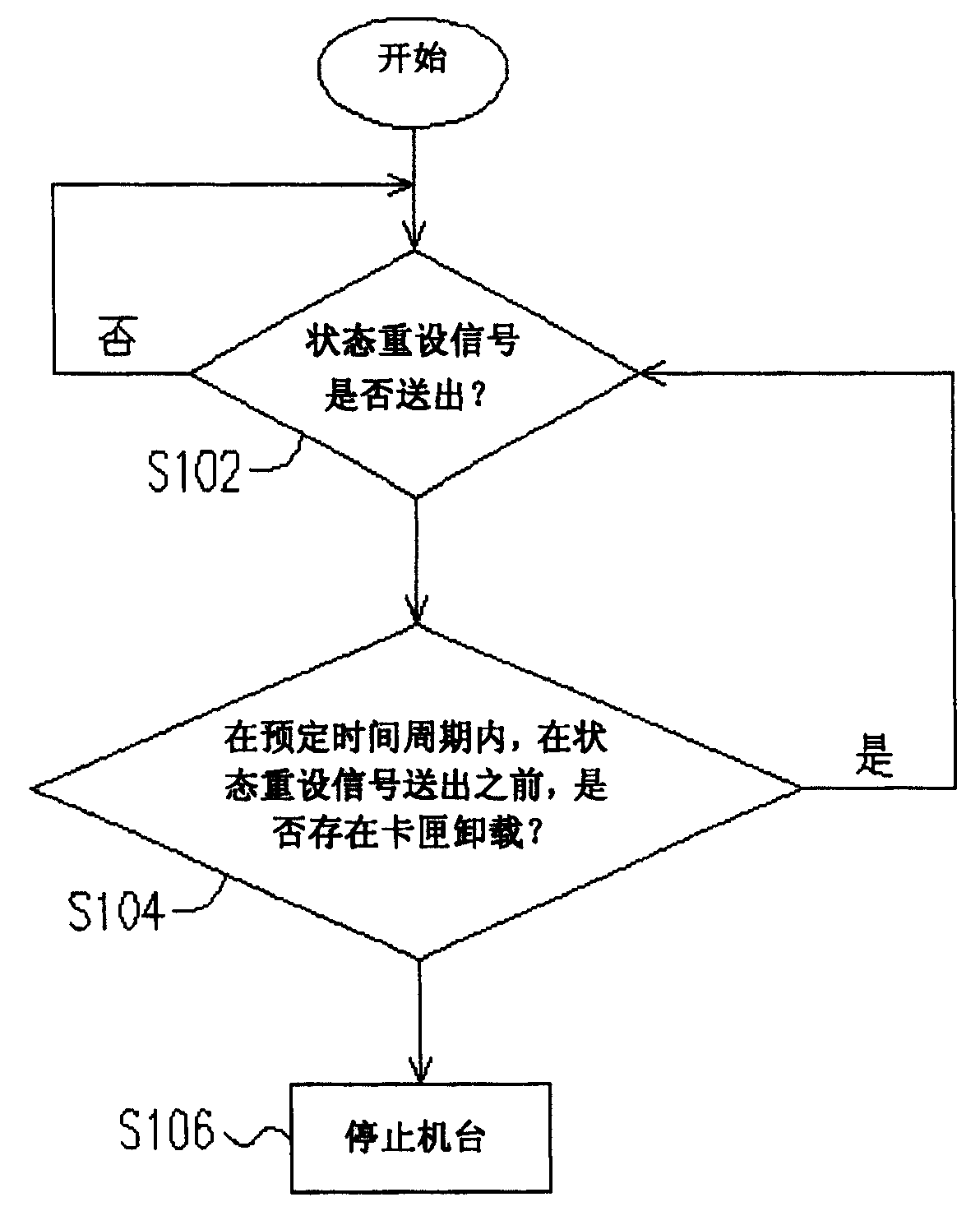

[0013] Currently, in a semiconductor factory, the transmission between semiconductor devices is based on the Semiconductor Equipment Communication Standard (SECS for short). The principle of the method for preventing repeated wafer deposition of the present invention is to use the state reset signal sent by the machine (for example: the event identification (event ID) 856 signal in SECS or the event identification 1856 signal in SECS) and the cassette unloading signal (eg: event recognition 51 signal in SECS). When the machine is in normal operation, it will not send the cassette unloading signal, only when picking up the goods, press unload (the cassette unloading signal will be sent), and the cassette in the machine will be taken out (the status reset signal will be sent ) will only appear. Therefore, the present invention utilizes the status reset signal and the cassette unloading signal to make a judgment. If only the status reset signal appears alone when the machine is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com