Air proportional boiler using air pressure sensor

A technology of air pressure and air pressure, which is applied in the direction of adjusting fuel supply, combustion method, air supply, etc., and can solve problems such as measurement flow error and expensive airflow sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

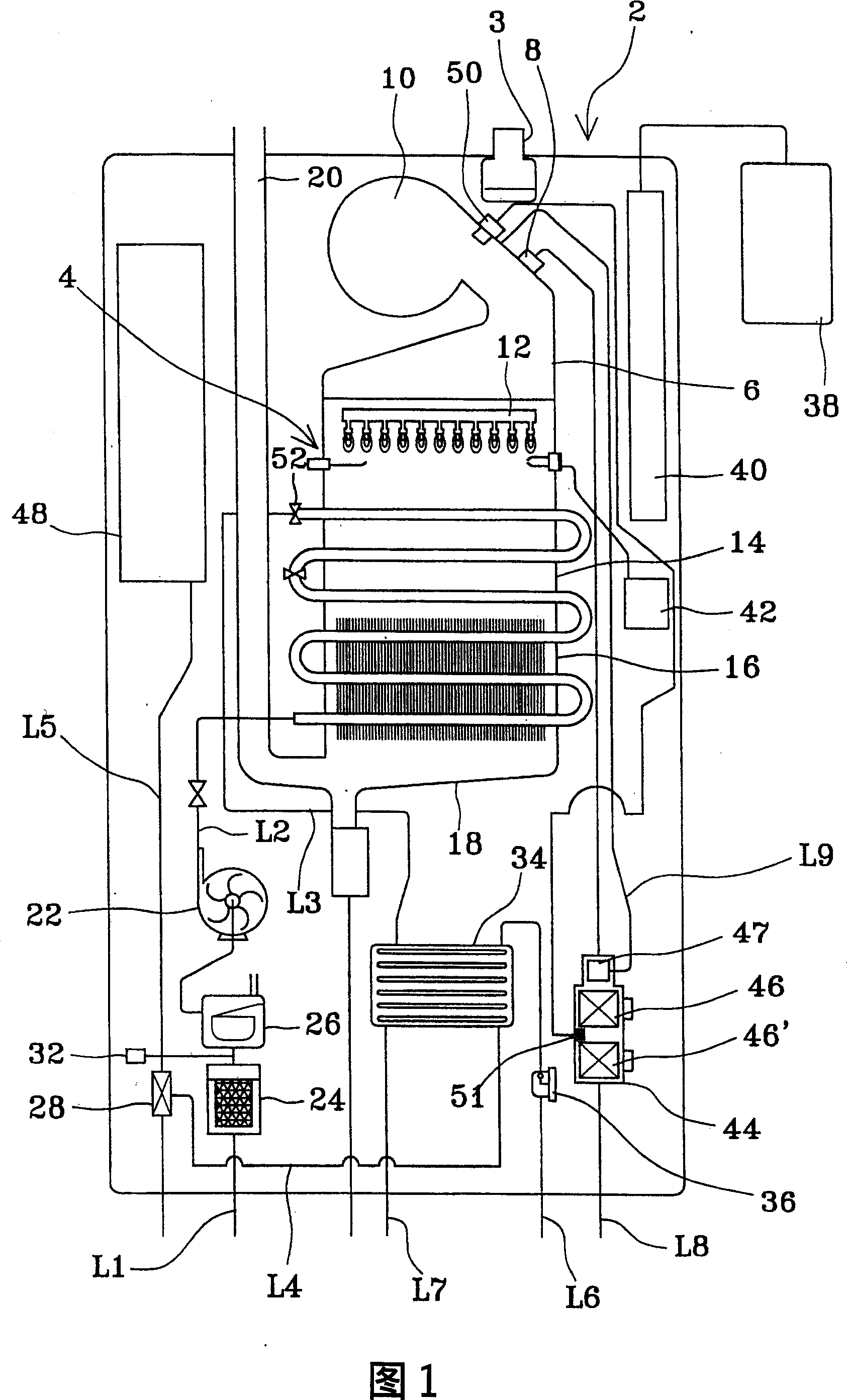

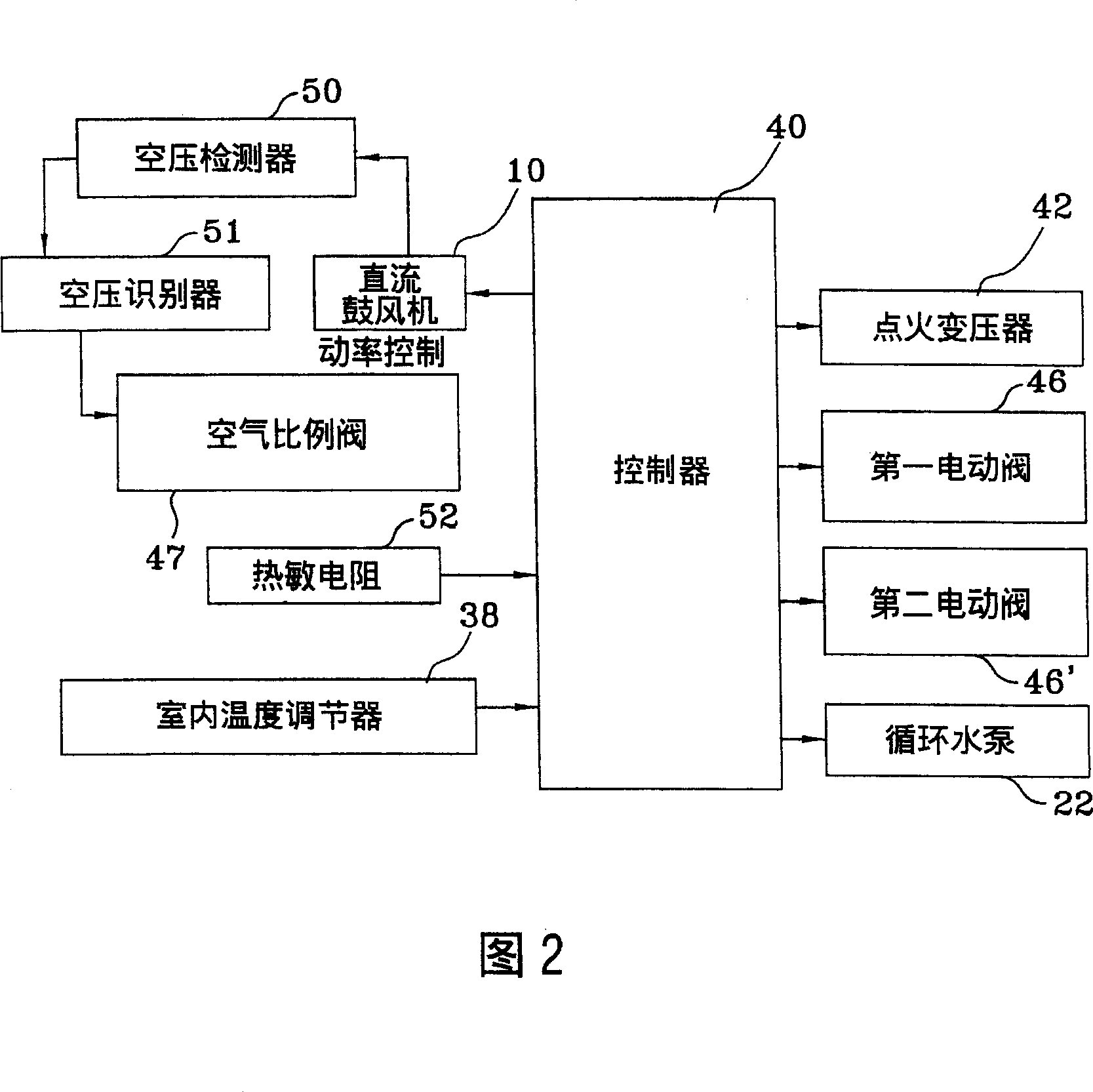

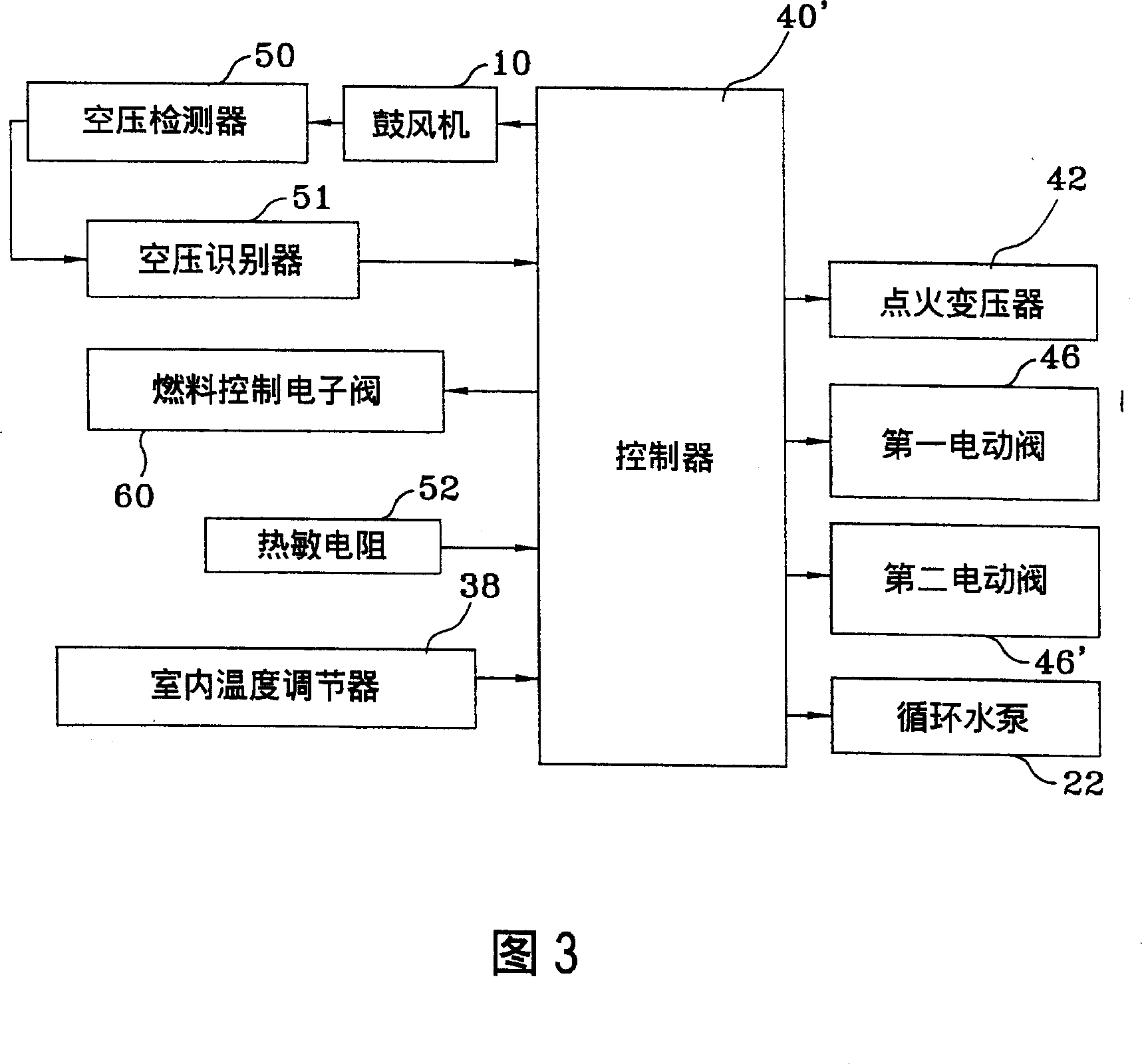

[0032] A preferred embodiment of the present invention will now be described with reference to the accompanying drawings. In addition, this embodiment does not limit the technical scope of the present invention, but only illustrates. Components that are the same as in the prior art bear the same reference numerals.

[0033] Fig. 3 is a block diagram of an air-proportional condensing boiler using an air pressure sensor according to the present invention.

[0034] As shown in Figure 3, the air-proportional condensing boiler includes: an air pressure detector 50 installed in the suction chamber 6, which is used to measure the air pressure sucked by the blower 10; an air pressure identifier 51, which uses It is used to convert the air pressure measured by the air pressure detector into an electric signal and output the electric signal; a fuel control electric valve 60, which is used to adjust the amount of fuel to be supplied; a thermistor 52, which is used to detect the circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com