Method for working ultrafine conical rolling bearing

A technology for roller bearings and superfinishing, applied in the direction of superfinishing machines, roller bearings, rolling contact bearings, etc., can solve the problems of reduced processing efficiency, increased waste of superfinishing stones, and inability to use long superfinishing stones, etc. problems, to achieve the effect of reducing replacement frequency, eliminating length restrictions, and eliminating obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

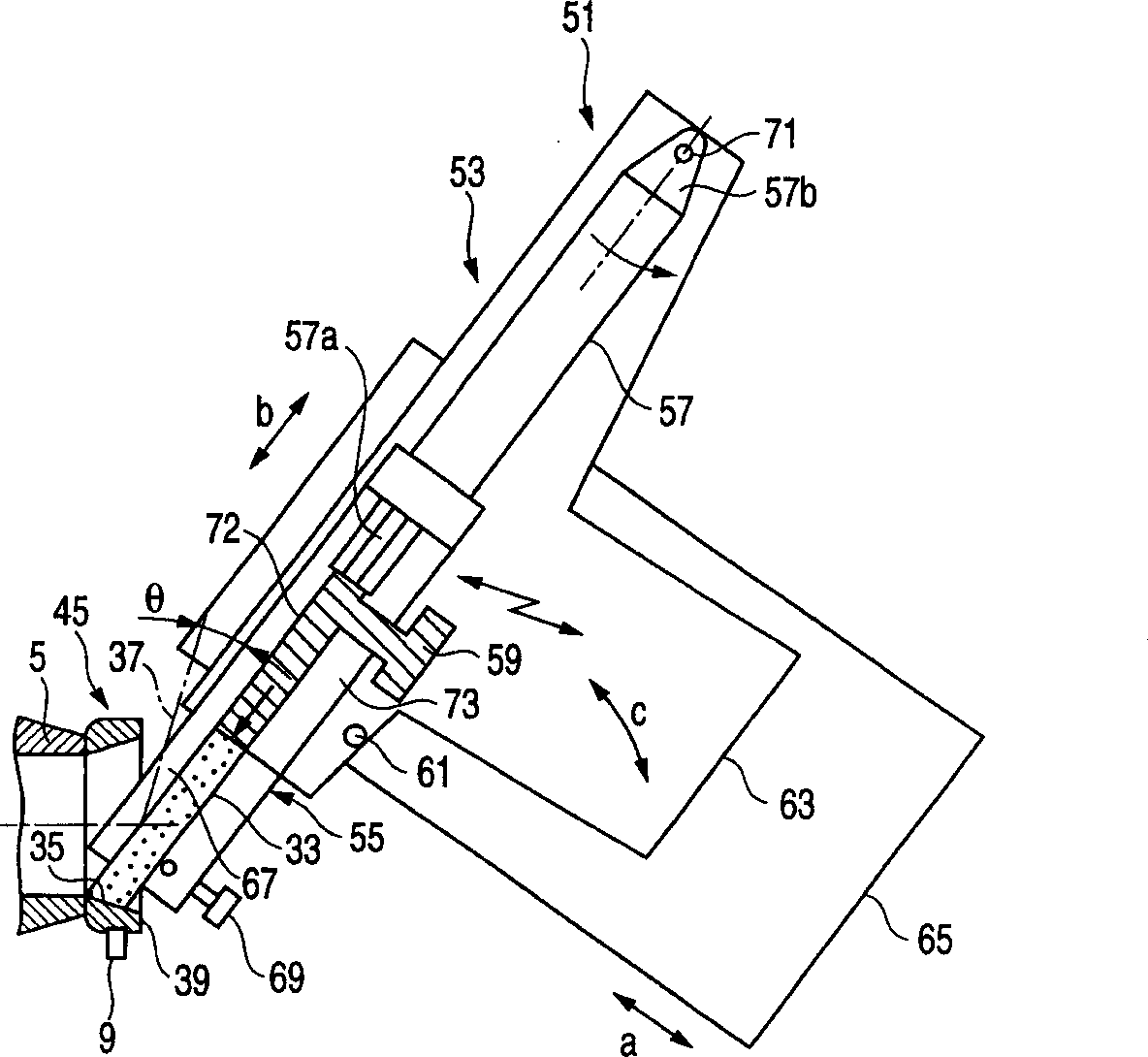

[0028] Now, preferred embodiments of a method and apparatus for superfinishing a tapered roller bearing according to the present invention will be described with reference to the accompanying drawings.

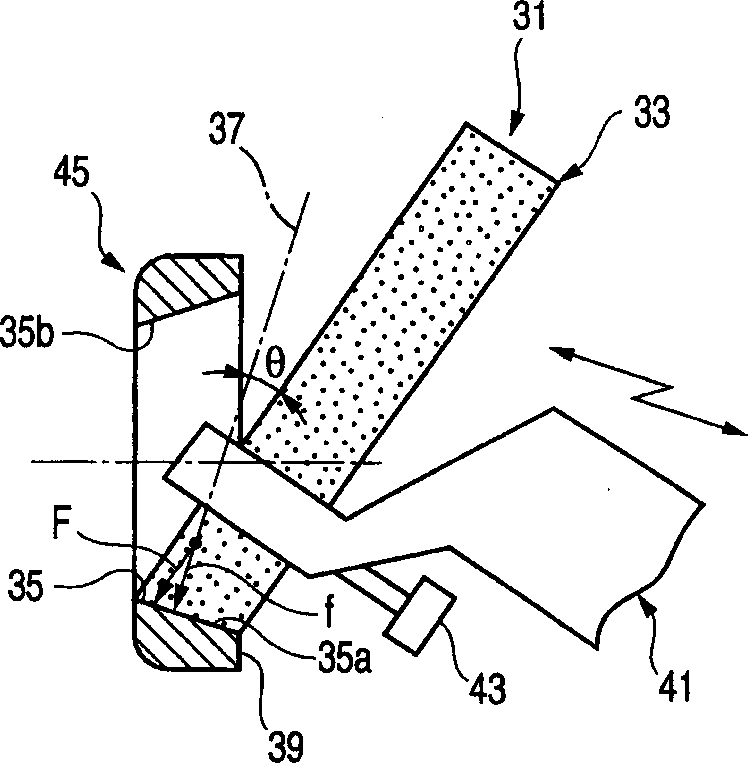

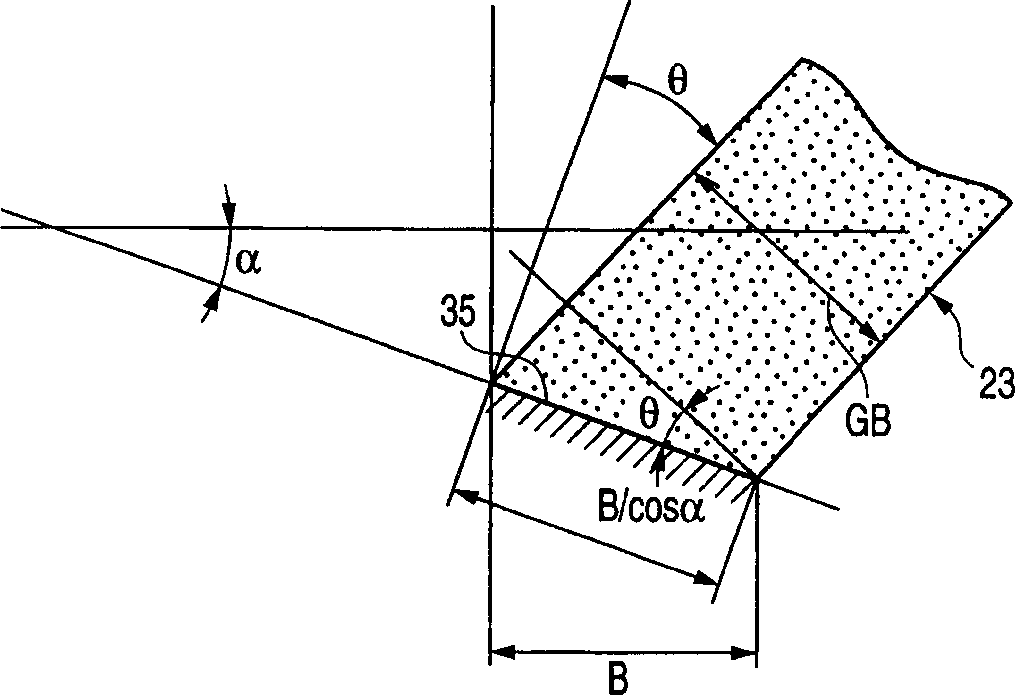

[0029] figure 1 is a partial sectional view of the main part of the superfinishing apparatus according to the first embodiment of the present invention. figure 2 It is an explanatory diagram of the range of the inclination angle of the ultra-finishing stone.

[0030] The superfinishing device according to the first embodiment of the present invention comprises a superfinishing stone holder 41, and this superfinishing stone holder 41 holds the superfinishing stone 33, and at this time, the superfinishing stone 33 corresponds to The vertical line 37 of the race surface 35 is inclined towards the outside of said outer face 39 of said outer ring. In addition, if Figure 7 As shown, the superfinishing device 31 includes a back plate 5 , a push roller 7 , a shoe 9 , a press cyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com