Punch

A technology of hole punch and hole shaft, which is applied in the field of hole punch, and can solve the problems of large-scale hole punch, weight increase, and heavier operating handle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

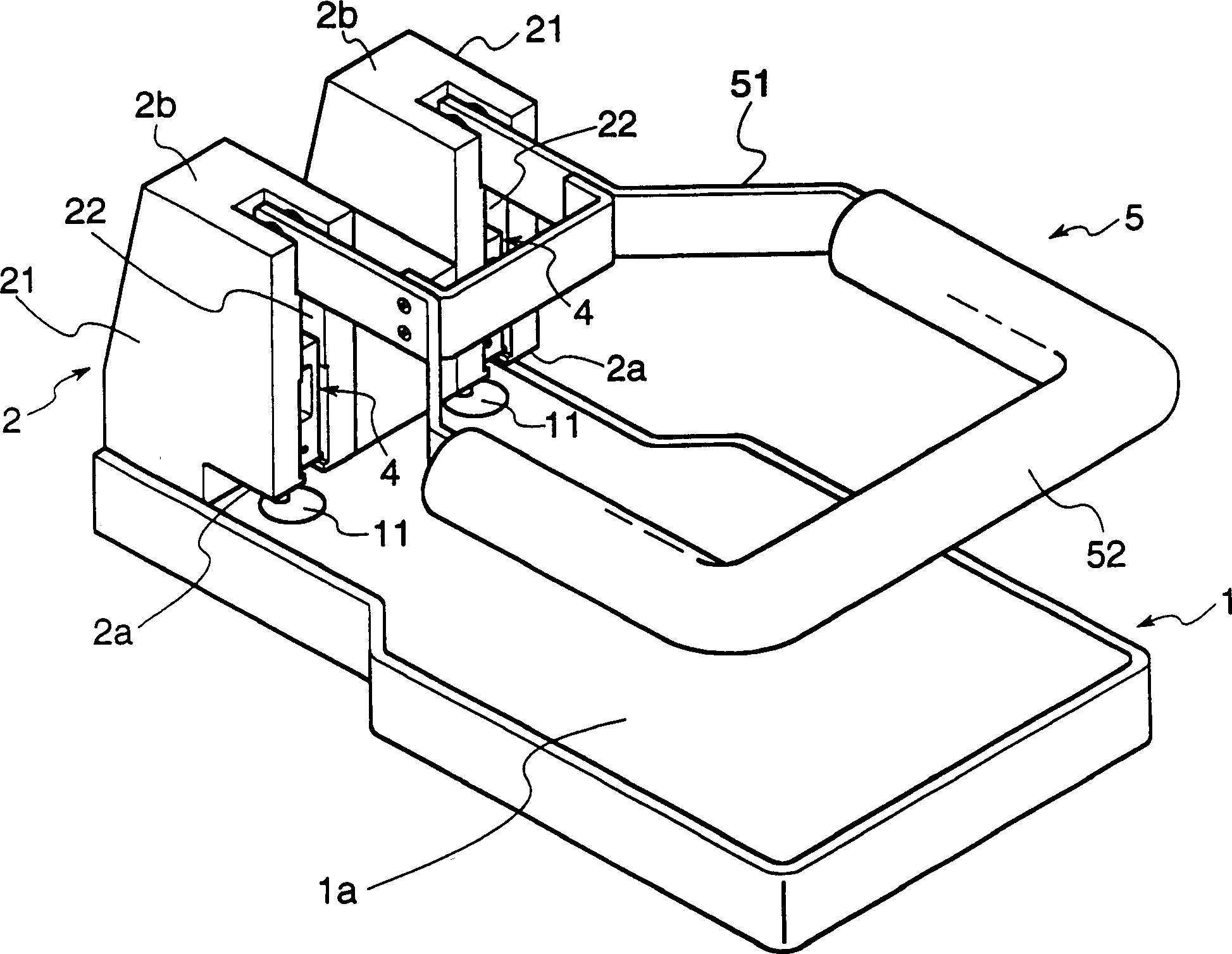

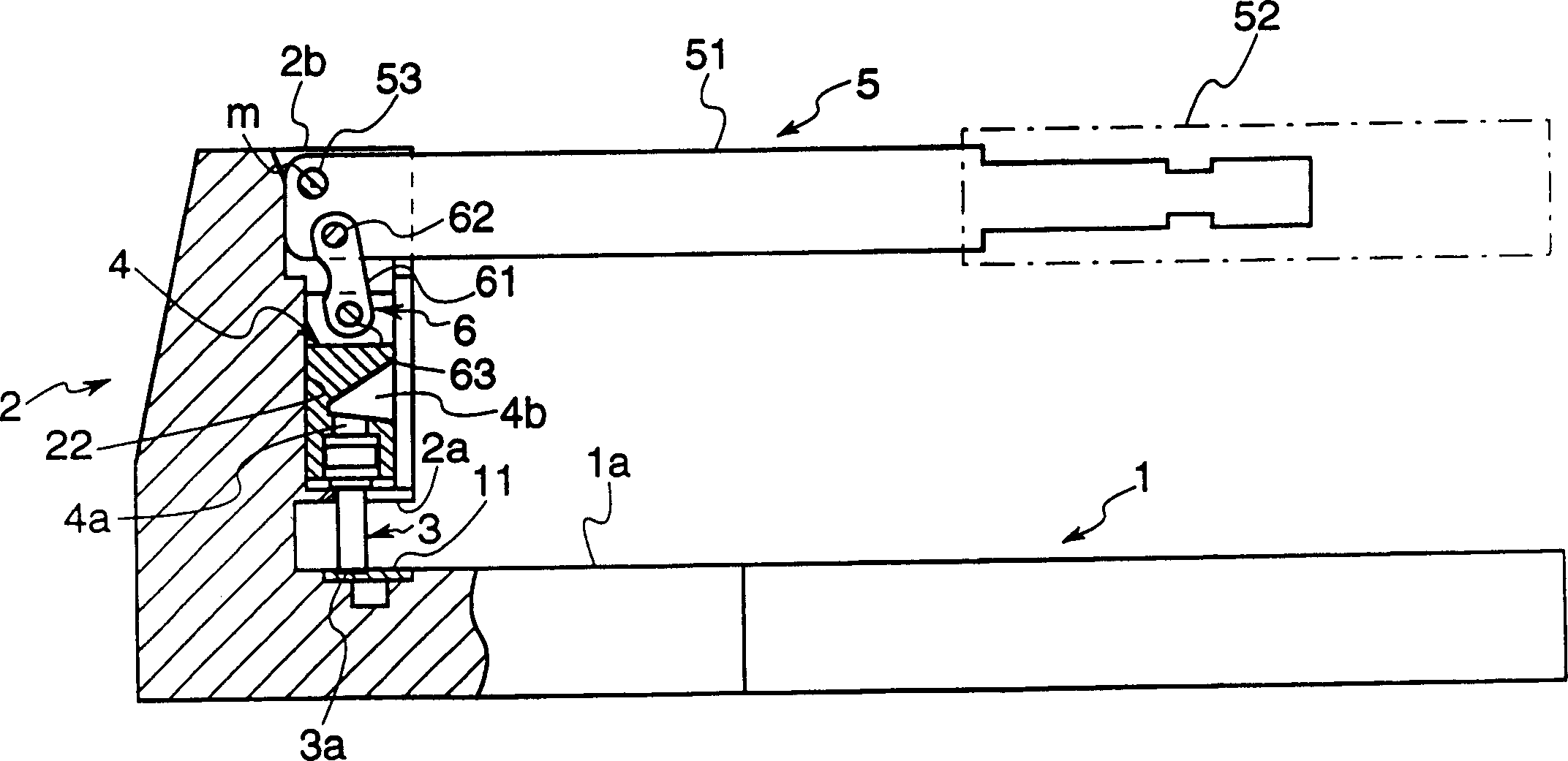

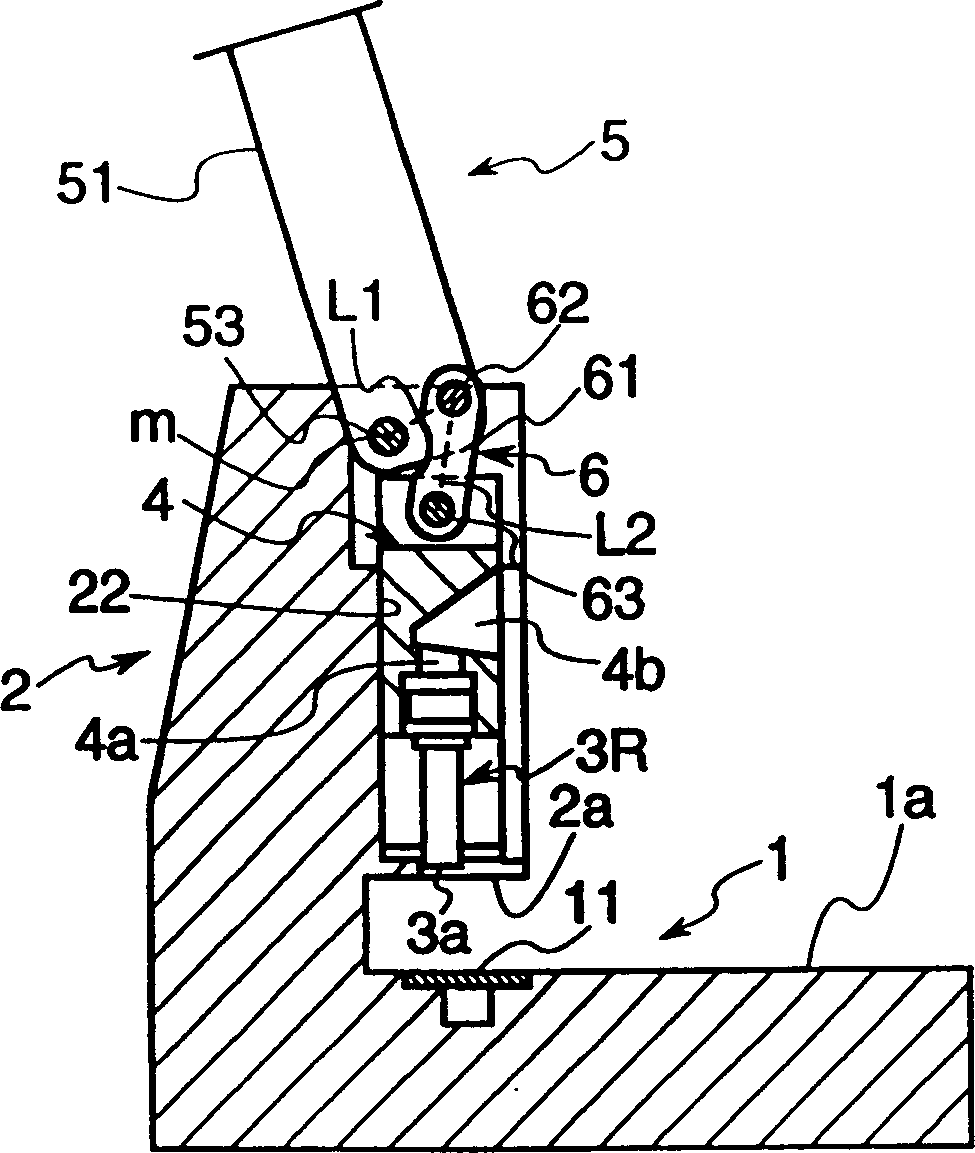

[0024] Hereinafter, one embodiment of the present invention will be described with reference to the drawings.

[0025] The puncher of this embodiment, as figure 1 as well as figure 2 As shown, it includes: a base 1; a holding member 2 integrally erected from one side of the upper end (the direction in which the paper is inserted) of the base 1; Pedestal 4; the base end side is rotatably supported on the upper end side of the above-mentioned holding member 2; 6.

[0026] The base 1 is a plate-shaped base with sufficient rigidity to support the operating handle 5 as the holding member 2 and its accessories. While the upper surface is used as the paper placement surface 1a, the punching shaft near its upper end 3, a resin circular spacer 11 that receives the tip 3a of the same punching shaft 3 is embedded in a state where its upper surface and the loading surface 1a are substantially the same.

[0027] The holding member 2 protrudes forward relative to the part contacting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com