Device and method for maintaining data consistery of sheet binder feeder

A feeder and placement machine technology, applied in the direction of electrical components, electrical components, etc., can solve the problems that the patch material cannot be used correctly, the feeder cannot sense and automatically control and measure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

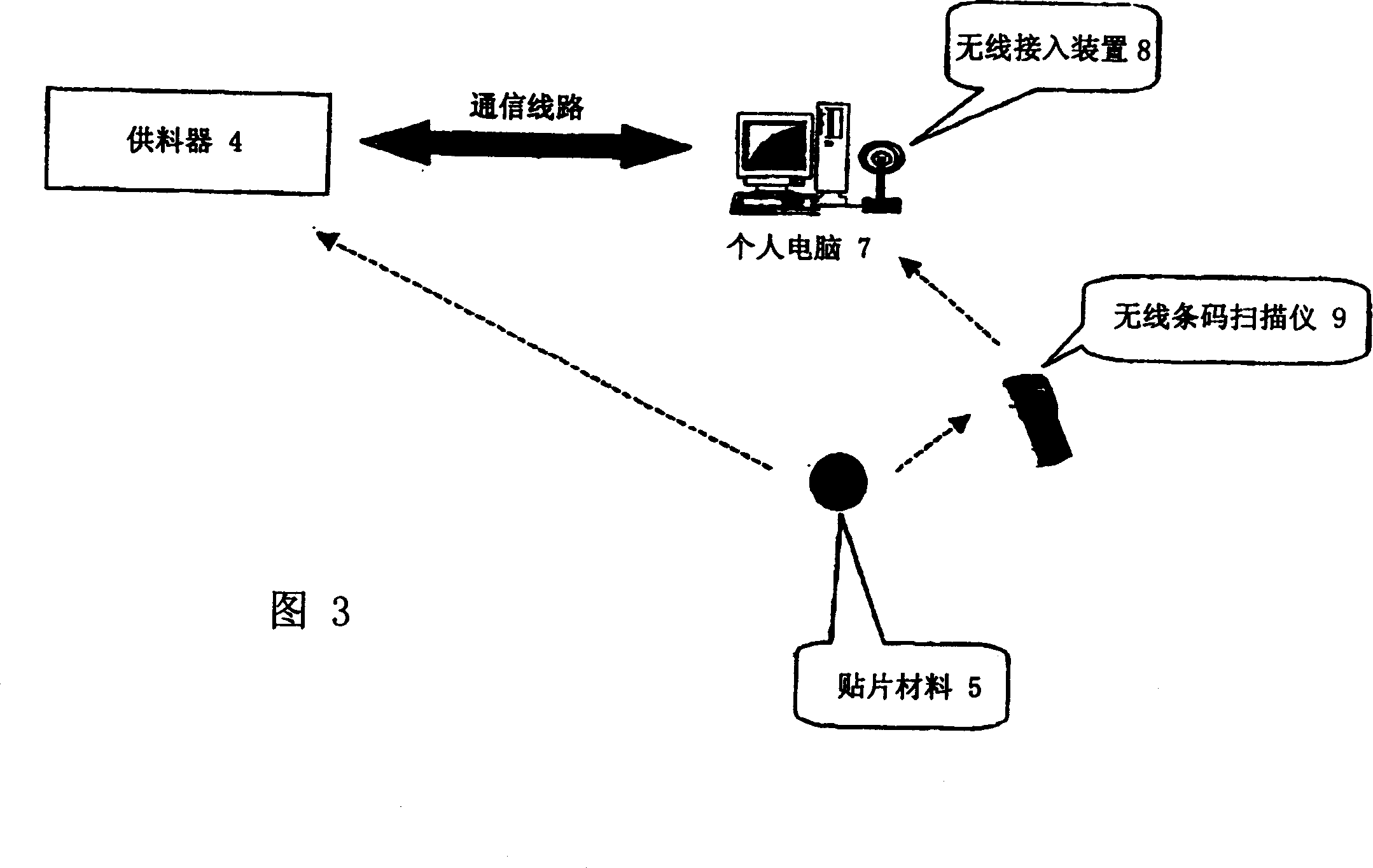

[0055] The device and method for keeping the information of the feeder consistent in the chip mounter of the present invention will be described in detail below with reference to the accompanying drawings.

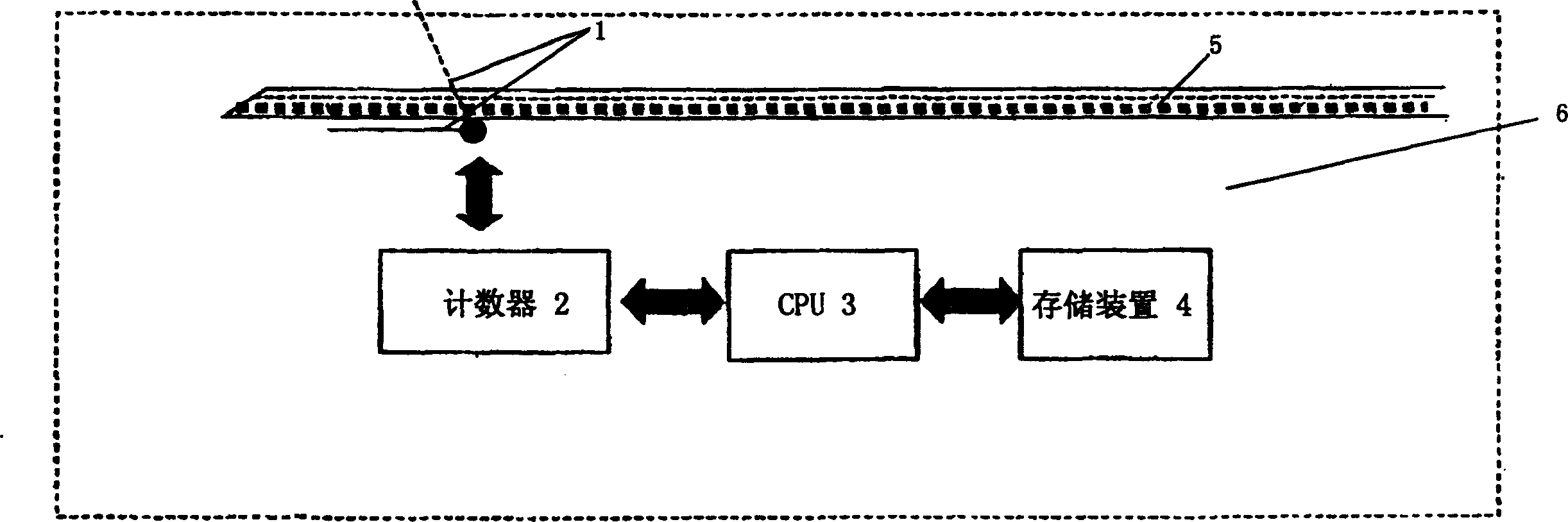

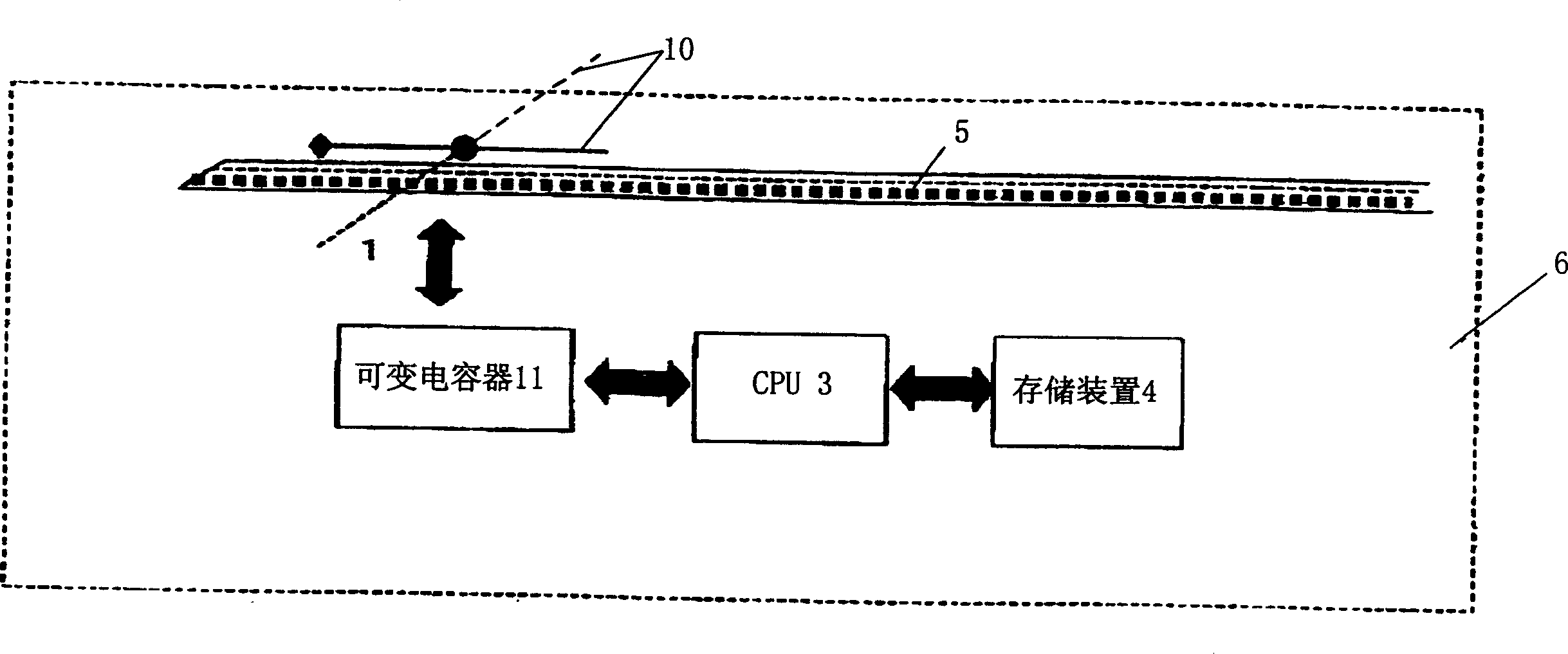

[0056] figure 1 It is a schematic diagram of the structure of the mounter feeder device according to an embodiment of the present invention, such as figure 1 As shown, the device is made up of a feeder 6, a counter 2, a CPU 3 and a storage device 4; an elastic device 1 is installed on the feeder 6, and when the patch material 5 is placed on the feeder 6, the elastic device 1 means depressing, in such as figure 1 In the state (position) shown by the solid line, when the patch material 5 is removed from the feeder, the elastic device 1 will automatically pop up, as figure 1 The state (position) shown by the dotted line in the middle.

[0057] A dedicated effective flag is set in the storage device 4 of the feeder device of the placement machine of the present invention, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com