Double-attention-guided rotary machine health assessment method

A technology for rotating machinery and health assessment, applied in neural learning methods, computer components, instruments, etc., can solve problems such as limited regression performance, inability to work effectively, differences in feature distribution, etc., to improve global feature learning and minimize distribution. Differences, the effect of improving evaluation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

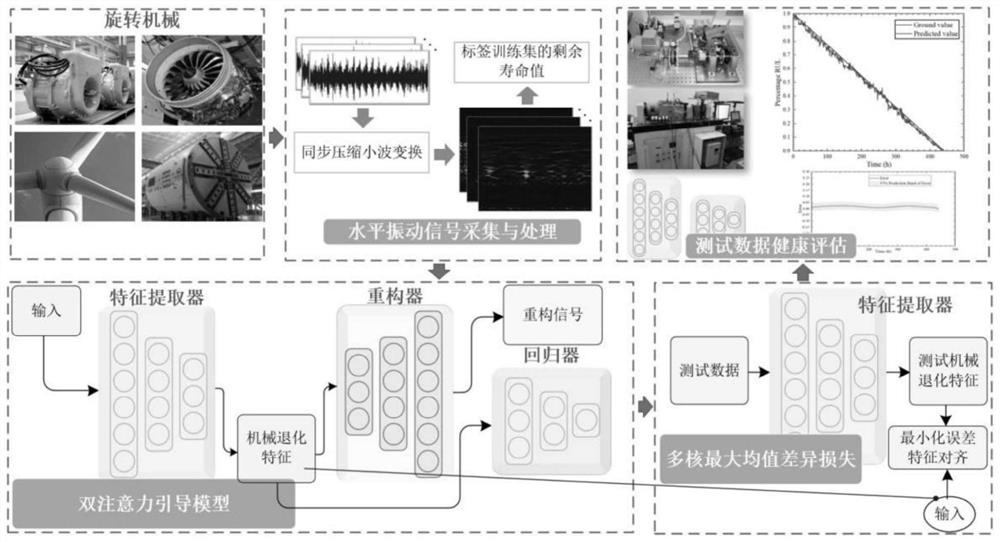

[0060] A double-attention-guided rotating machinery health assessment method in this embodiment can be referred to figure 1 , including the following steps:

[0061] S1, collect the horizontal vibration signal of the rotating machinery, process the horizontal vibration signal to obtain the time-frequency diagram data, divide all the time-frequency diagram data into a test set and a training set, and then mark the test set with the remaining life value;

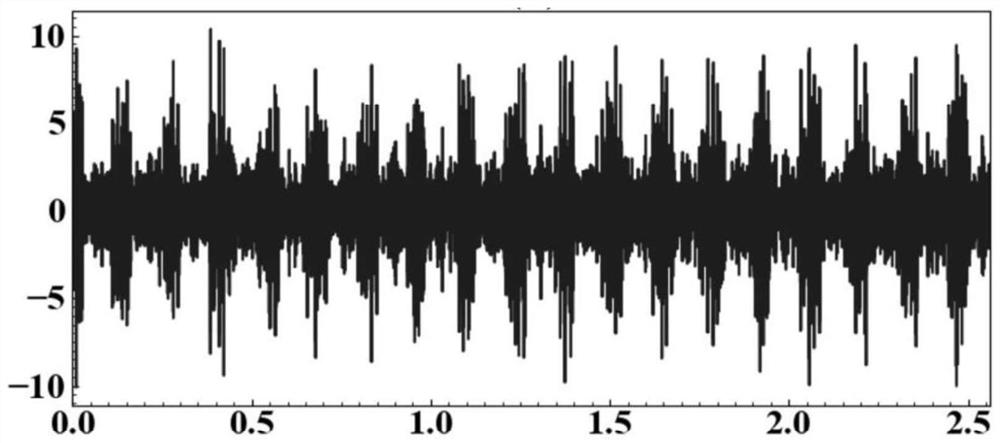

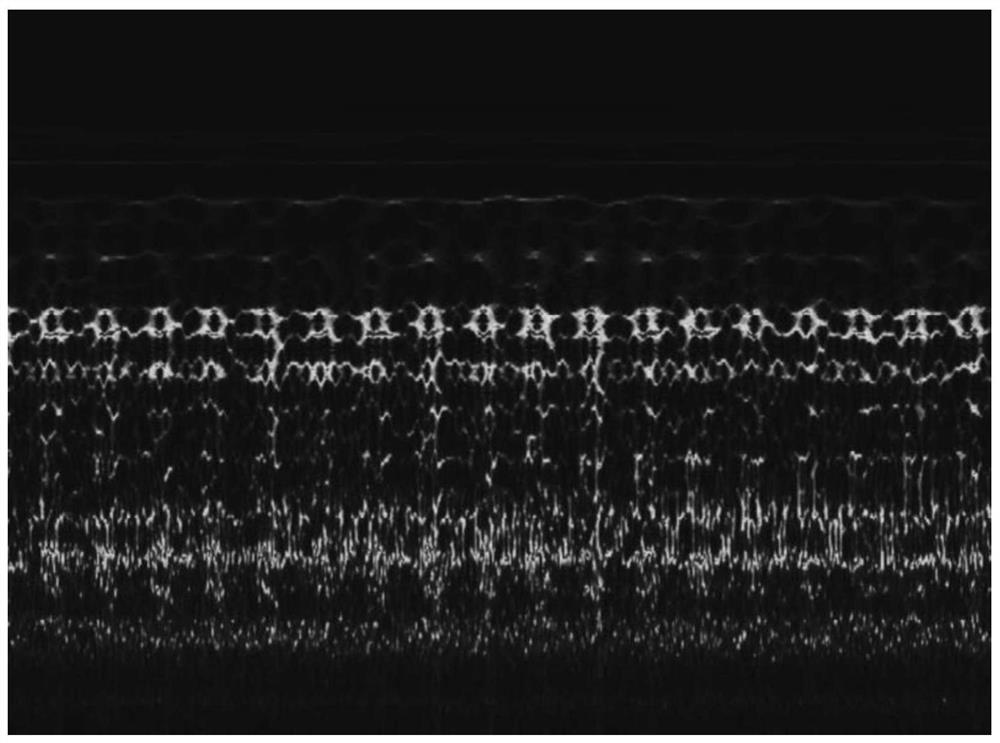

[0062] As a specific implementation form, a three-axis acceleration sensor can be used to collect horizontal vibration signals of rotating machinery, figure 2 It is the waveform diagram of the collected horizontal vibration signal, and the vibration signal is processed by synchronous compression wavelet transform to obtain the time-frequency diagram, image 3 is the time-frequency diagram of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com