Glass sheet for decoration

A glass plate and decorative film technology, applied in decorative arts, decorative structures, special decorative structures, etc., can solve the problems of inability to manufacture decorative films and inability to manufacture delicate metal layer decorative films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

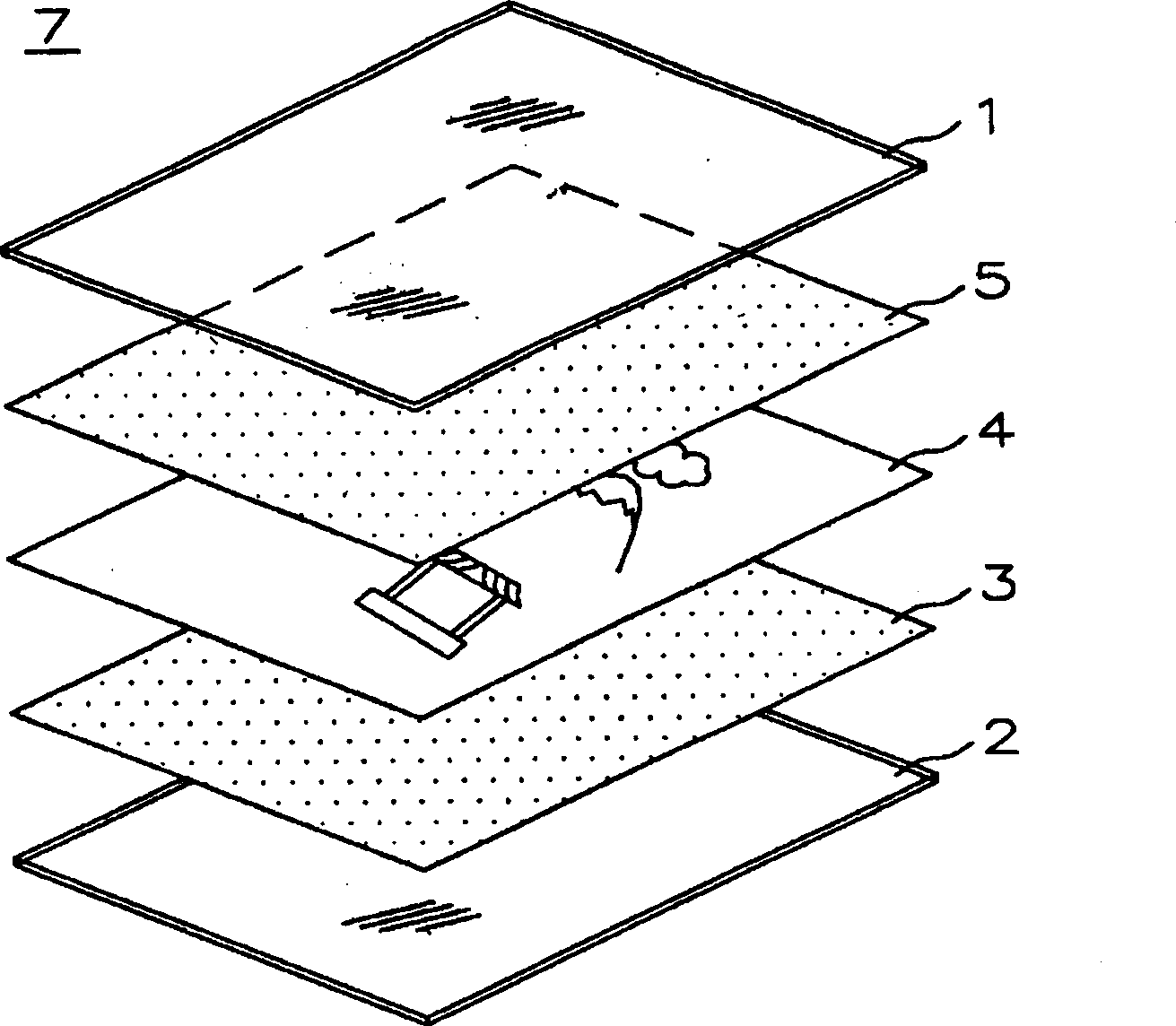

[0010] The present invention and its many advantages can be better understood by referring to the following detailed description and accompanying drawings. The term "pattern" means a figure formed on the aluminum layer, and the term "shape" means an outline formed by the outer surface of the aluminum layer.

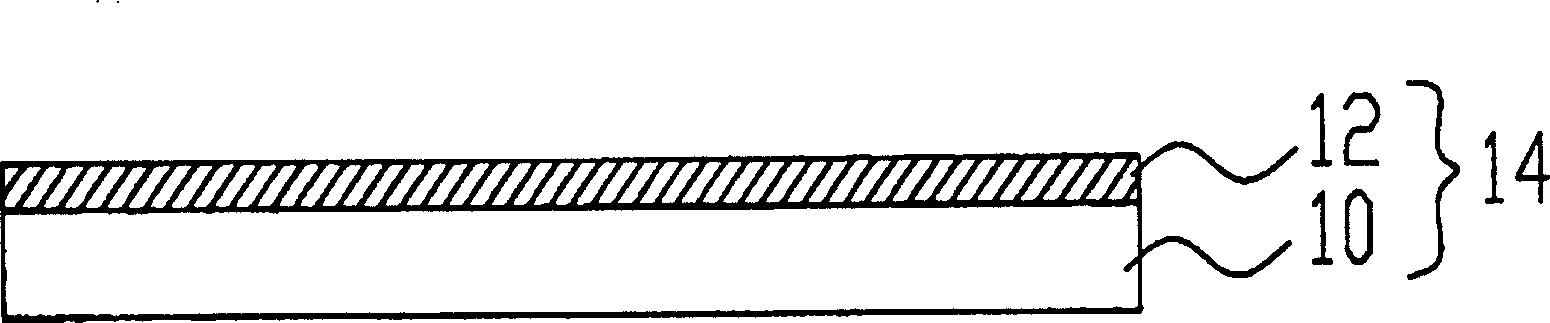

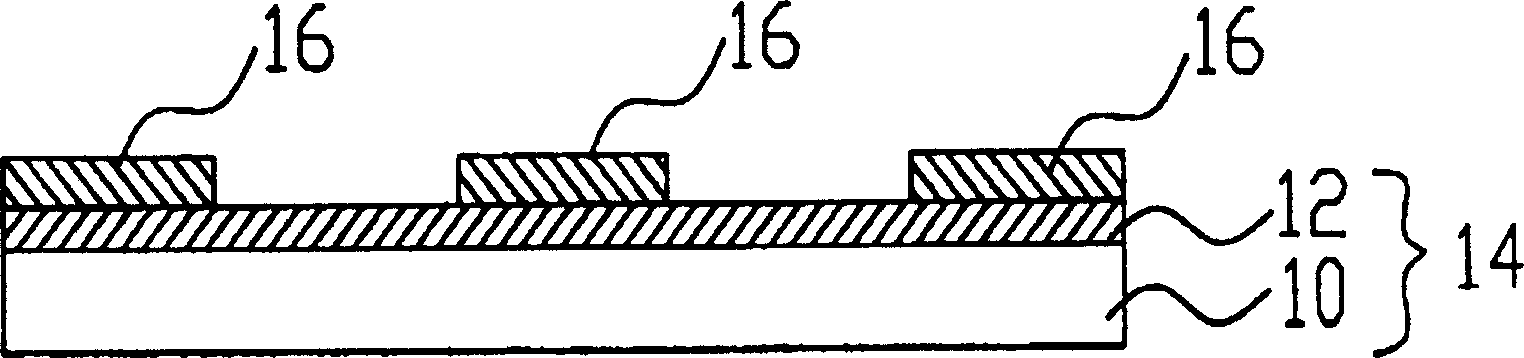

[0011] Figure 2a to Figure 2c is a cross-sectional view showing a process of forming a decorative film used in a decorative glass panel according to an embodiment of the present invention. Such as Figure 2a As shown, a starting member 14 is formed by laminating an aluminum layer 12 on a base layer 10 . The base layer 10 is made of a synthetic resin film having excellent transparency and hardness, so that the pattern and shape of the aluminum layer 12 formed on the base layer 10 can be seen through the base layer 10 . The base layer 10 can also be made of a colored translucent film as required. The transparent base layer 10 can be made from one of transparent PET (po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com