Printing method combining photoetching technology and digital jet printing

A technology of digital jet printing and lithography technology, applied in the field of printing, can solve the problem that the visual effect is not so strong, and achieve the effect of improving anti-counterfeiting, strong tactile feeling, and ensuring the combined effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

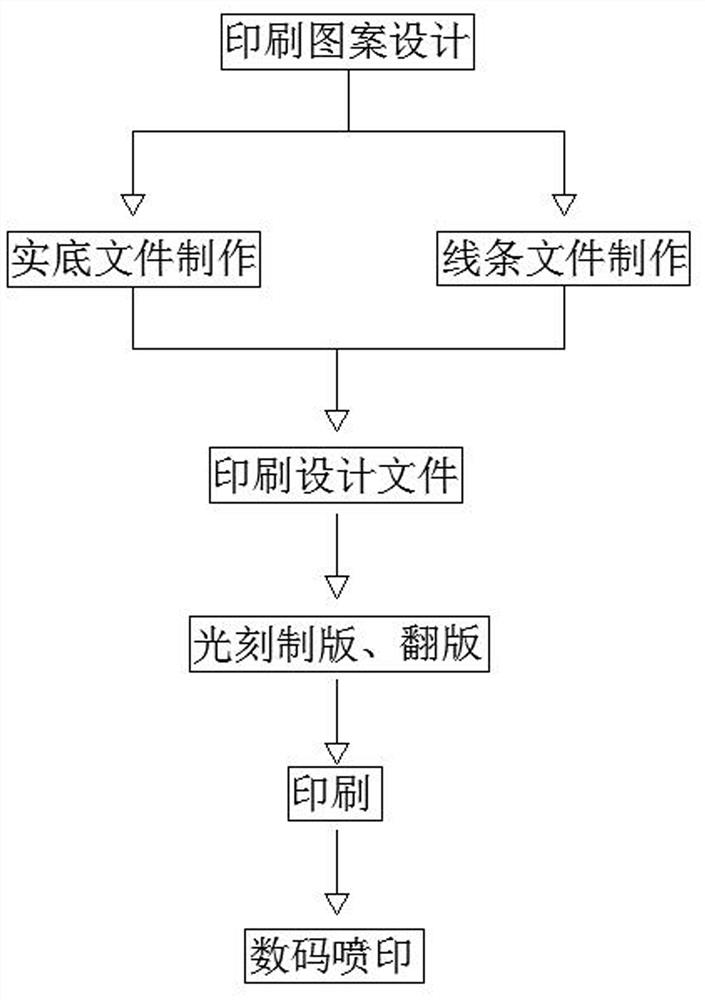

[0029] like figure 1 Shown, a lithographic printing method of digital printing techniques and combining, comprising the steps of:

[0030] Step 1): Printed pattern design;

[0031] Step 2): According to step 1), the printed pattern is designed, and the print design document is produced:

[0032] A. Factory production: Production software is AI, use C, K channel, according to the percentage of C, K according to digital inkjet light oil thickness;

[0033] In the present embodiment, the digital ink-jet Varnish thickness: 50 m, bottom real file, C, K is the percentage: 100%.

[0034] B. Line file production: Production software is Ai, use C, K channel, according to design requirements, adjust the line thickness;

[0035] In the present embodiment, the line thickness is: 0.08MM.

[0036] C. Printing file production: combination of faded files and line files as a print design file;

[0037] Step 3): Photocolite, release according to the print design file;

[0038] Step 4): Print;

[00...

Embodiment 2

[0043] like figure 1 Shown, a lithographic printing method of digital printing techniques and combining, comprising the steps of:

[0044] Step 1): Printed pattern design;

[0045] Step 2): According to step 1), the printed pattern is designed, and the print design document is produced:

[0046] A. Factory production: Production software is AI, use C, K channel, according to the percentage of C, K according to digital inkjet light oil thickness;

[0047] In the present embodiment, the digital ink-jet Varnish thickness: 50 m, bottom real file, C, K is the percentage: 100%.

[0048] B. Line file production: Production software is Ai, use C, K channel, according to design requirements, adjust the line thickness;

[0049] In the present embodiment, the line thickness is: 0.08MM.

[0050] C. Printing file production: combination of faded files and line files as a print design file;

[0051] Step 3): Photocolite, release according to the print design file;

[0052] Step 4): Print;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com