Excellent light transmission diffusibility synthetic resin formed product

A synthetic resin, diffusive technology, used in optics, optical components, diffusing components, etc., to achieve excellent industrial productivity, easy demolding, good balance of light transmittance and light diffusion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0112] The present invention will be described in more detail below by way of examples, but the present invention is not limited to these examples.

[0113] Evaluations in Examples were performed by the following methods.

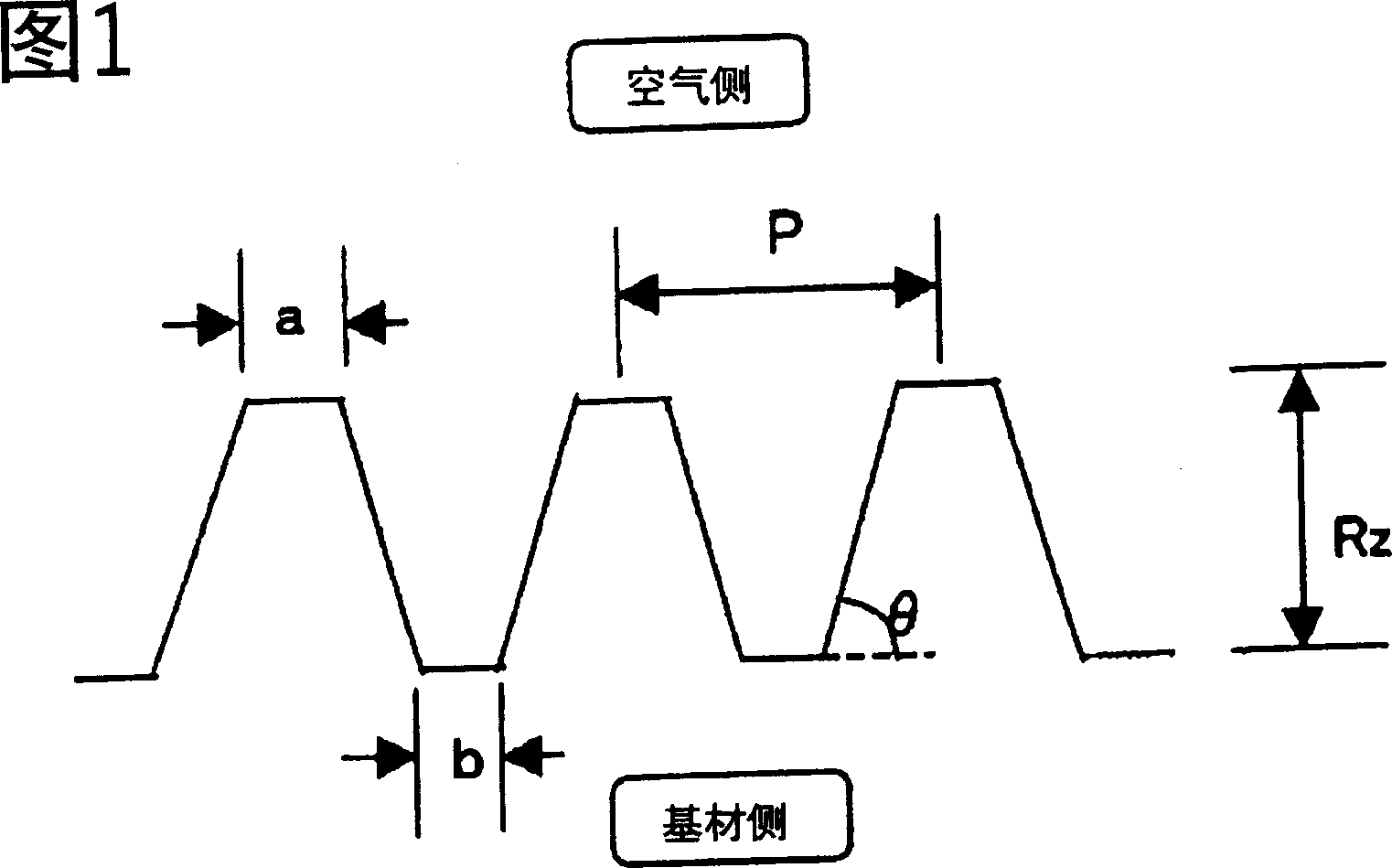

[0114] (1) Surface shape

[0115] The average height Rz of the shape model ( FIG. 1 ) was measured in accordance with JIS B0601-1994 using a universal surface shape measuring device SE-3C manufactured by Kosaka Laboratories Co., Ltd. The interval (pitch) P between the peaks was measured using an optical microscope manufactured by Nippon Kogyo Co., Ltd. and an image analysis optical microscope manufactured by Keyence Co., Ltd. Microfield VH-8000. The inclination angle θ of the concavo-convex was measured with an ultra-deep shape microscope (laser microscope) VF-7500 manufactured by Keyence Co., Ltd.

[0116] (2) Evaluation of release properties

[0117] After the synthetic resin molded plate molded by casting polymerization was cooled to room temperature,...

example 1

[0138] Example 1 (embodiment)

[0139] (1) Production of molded glass

[0140] A glass plate with a thickness of 10 mm was dipped in a fluorine-based acid etchant [Glass Matting Agent Lerite SX-20 manufactured by SEPPIC (France)] for 60 seconds at room temperature and washed with water to produce a mold glass having a desired surface shape.

[0141] (2) Face them so that the surface formed with the desired surface shape is on the inside, sandwich a soft vinyl chloride resin gasket (gasket) so that the gap is 2 mm, and assemble it into a glass cell.

[0142] Then, 100 parts by weight of methyl methacrylate partial polymer, 0.1 part by weight of 2,2'-azobisisobutyronitrile, 0.03 parts by weight of 2-(2'-hydroxy-5-methylphenyl)benzotriazole parts by weight, 0.1 parts by weight of stearic acid. The slurry was poured into a glass tank, heated and polymerized in 60°C warm water for 2 hours, and heated in a 120°C furnace for 2 hours. After cooling, the glass tank is peeled off to ...

example 2

[0144] Example 2 (embodiment)

[0145] Using the molded glass used in Example 1, face it so that the surface formed with the desired surface shape is on the inside, sandwich a soft vinyl chloride resin gasket so that the gap is 2 mm, and assemble it into a glass cell .

[0146] Then, 5 parts by weight of commercially available silicone beads were mixed with 20 parts by weight of methyl methacrylate, and mixed and stirred for 15 minutes. Thereafter, 68.5 parts by weight of methyl methacrylate partial polymer, 7.0 parts by weight of neopentyl glycol dimethacrylate, and 0.03 parts by weight of 2-(2'-hydroxy-5-methylphenyl)benzotriazole were added. 0.01 parts by weight of stearic acid, 0.1 parts by weight of 2,2'-azobis(2,4-dimethylvaleronitrile) and 1,1-bis(tert-butyl peroxide)-3,3,5 - 0.1 part by weight of trimethylcyclohexane, stirred for 30 minutes. The slurry was poured into a glass tank, heated and polymerized in 60°C warm water for 2 hours, and heated in a 120°C furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com