Curable organopolysiloxane release agent composition for thermal paper, thermal paper, and thermal recording label sheet

A technology of hydrogenated polysiloxane and polysiloxane, which is used in film/sheet-like adhesives, adhesives, other chemical processes, etc., can solve the problem that thermal paper cannot be used and hinder the industrial popularization of silicone-based release agents. , thermal head printing is not obvious and other problems, to achieve the effect of excellent peelability and adhesion, excellent handling workability, and good industrial productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

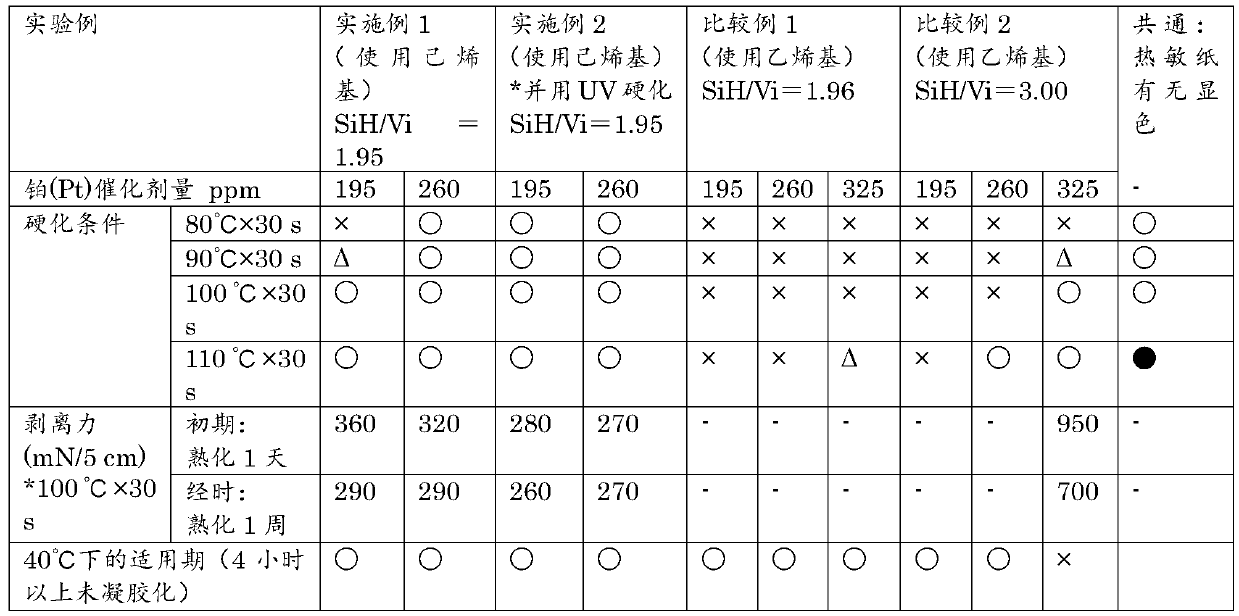

[0121] [Example 1] Composition 1

[0122] (A) Polydimethylsiloxane (viscosity 200mPa·s, vinyl (CH 2 = CH-) moiety content 1.15% by mass) 93.76 parts, (B1-1) 3.00 parts of dimethylmethylhydrogenpolysiloxane having a viscosity of 25 mPa·s and trimethylsiloxy groups at both ends of the molecular chain, (B1-2) 3.00 parts of dimethylmethylhydropolysiloxane with a viscosity of 20 mPa·s and both ends of the molecular chain terminated by trimethylsiloxy groups, (C) chloroplatinic acid-1,3-divinyl - 1,1,3,3-tetramethyldisiloxane complex (platinum metal content: 0.6% by mass) is 195, 260 ppm in the total composition based on the amount of platinum metal, (D1) 1-acetylene 0.23 part of 1-cyclohexanol (ETCH) and 0.01 part of methyl (tris(1,1-dimethyl-2-propynyloxy)) silane were uniformly mixed to obtain curable organopolysiloxane combination. Table 1 shows the results of evaluation of curability and the like on the thermal paper by forming a cured layer in a hot air circulation oven at ...

Embodiment 2

[0123] [Example 2] Composition 2

[0124] A curable organopolysiloxane composition was obtained in the same manner as in Example 1, except that 0.01 part of (E) diethoxyacetophenone was added and prepared in the composition 1. The cured layer was formed on the thermal paper at the cured temperature and cured time shown in Table 1 with respect to the composition of each amount of platinum, and the cured properties are shown in Table 1. Wherein, because composition 2 has ultraviolet curability, form a cured layer on the heat-sensitive paper with the curing temperature and curing time shown in Table 1 in the hot air circulation oven, and then carry out ultraviolet radiation (EYE GRAPHICS (Stock) Eye Grande, Total irradiation energy: 110mJ / cm 2 ), thereby forming a cured layer on the thermal paper, and the evaluation results of its curability and the like are shown in Table 1. The SiH / Vi ratio of composition 2 was 1.95 similarly to composition 1.

Embodiment 3-1

[0134] [Example 3-1] Composition 3-1

[0135] 0.50 parts of (B2) dimethylmethylhydropolysiloxane with a viscosity of 200 mPa·s and both ends of the molecular chain terminated by trimethylsiloxy groups were added to the composition 1, which was referred to as composition 3 -1. In addition, in composition 1, the mass ratio (=SiH / Vi ratio) of the hydrogen atoms bonded to the silicon atoms in the components (B1) to (B3) to the vinyl moiety in the component (A) was 2.16 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com