Diaphragm combination structure for pressure gauge

A technology combining structure and pressure gauge, applied in the direction of elastic deformation gauge fluid pressure measurement, etc., can solve the problems affecting the sealing effect of pressure gauge, achieve stable compression, reliable sealing, and prevent scratching the oil seal ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

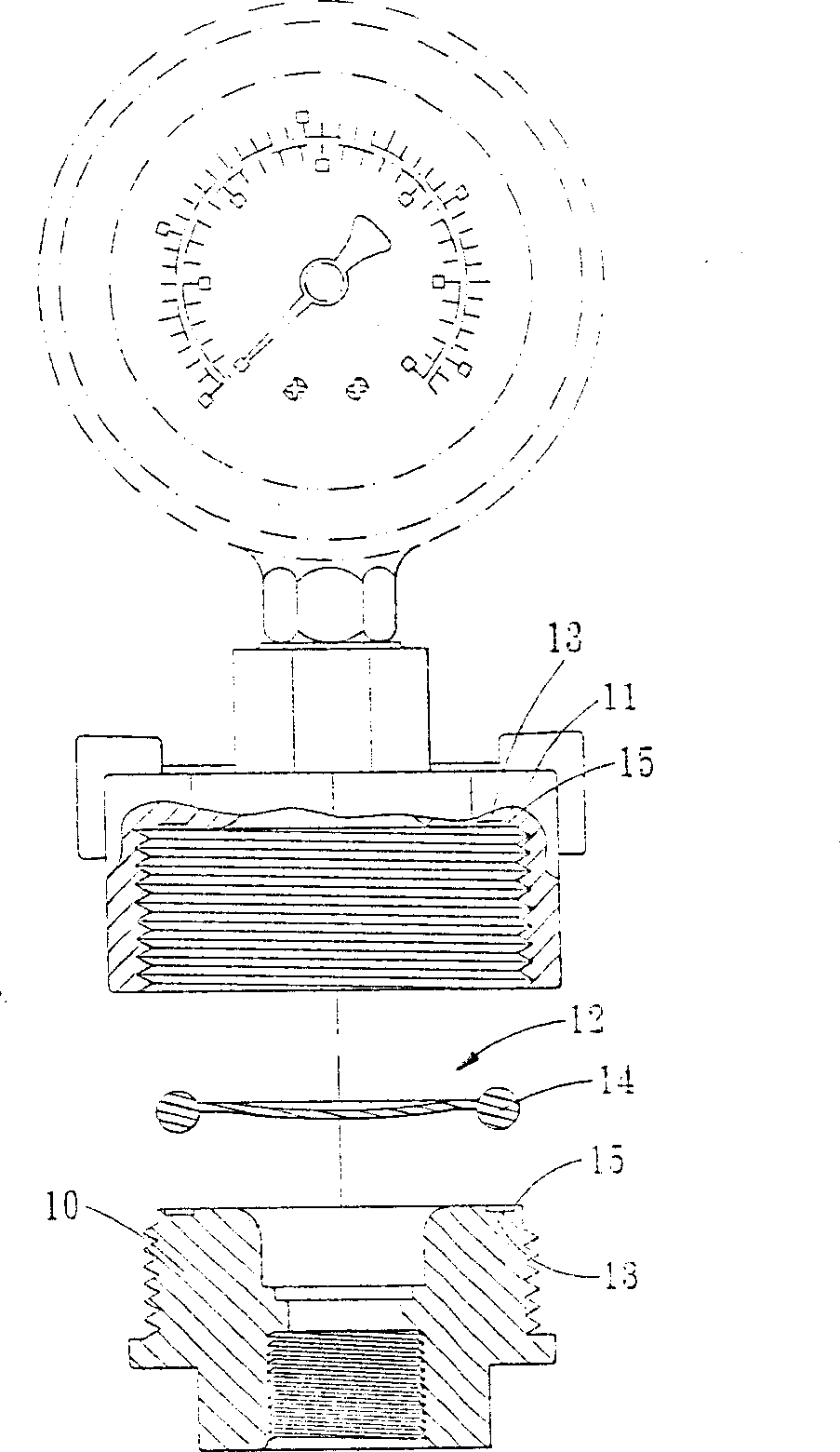

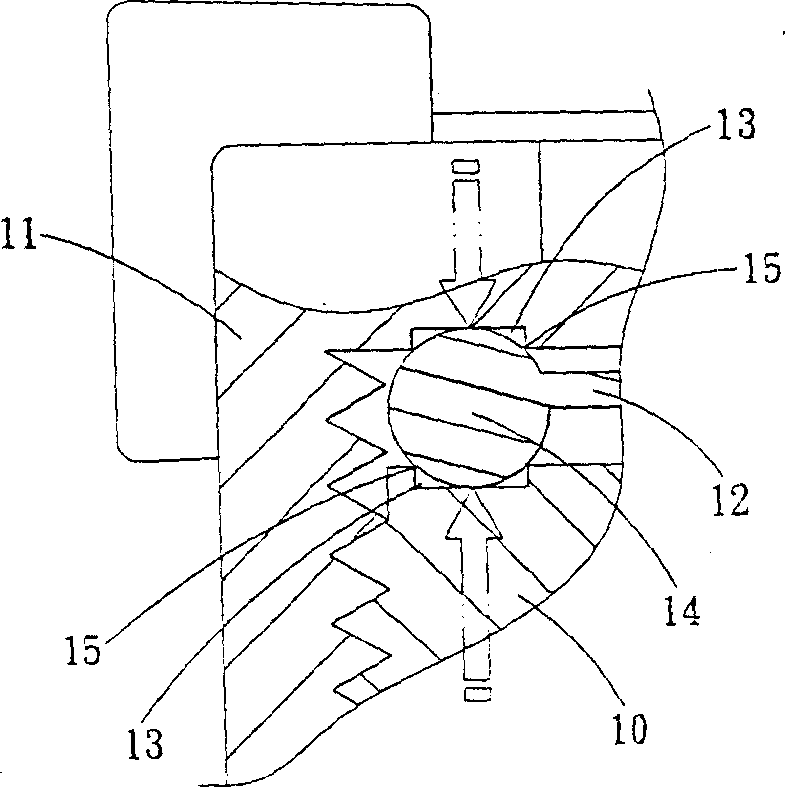

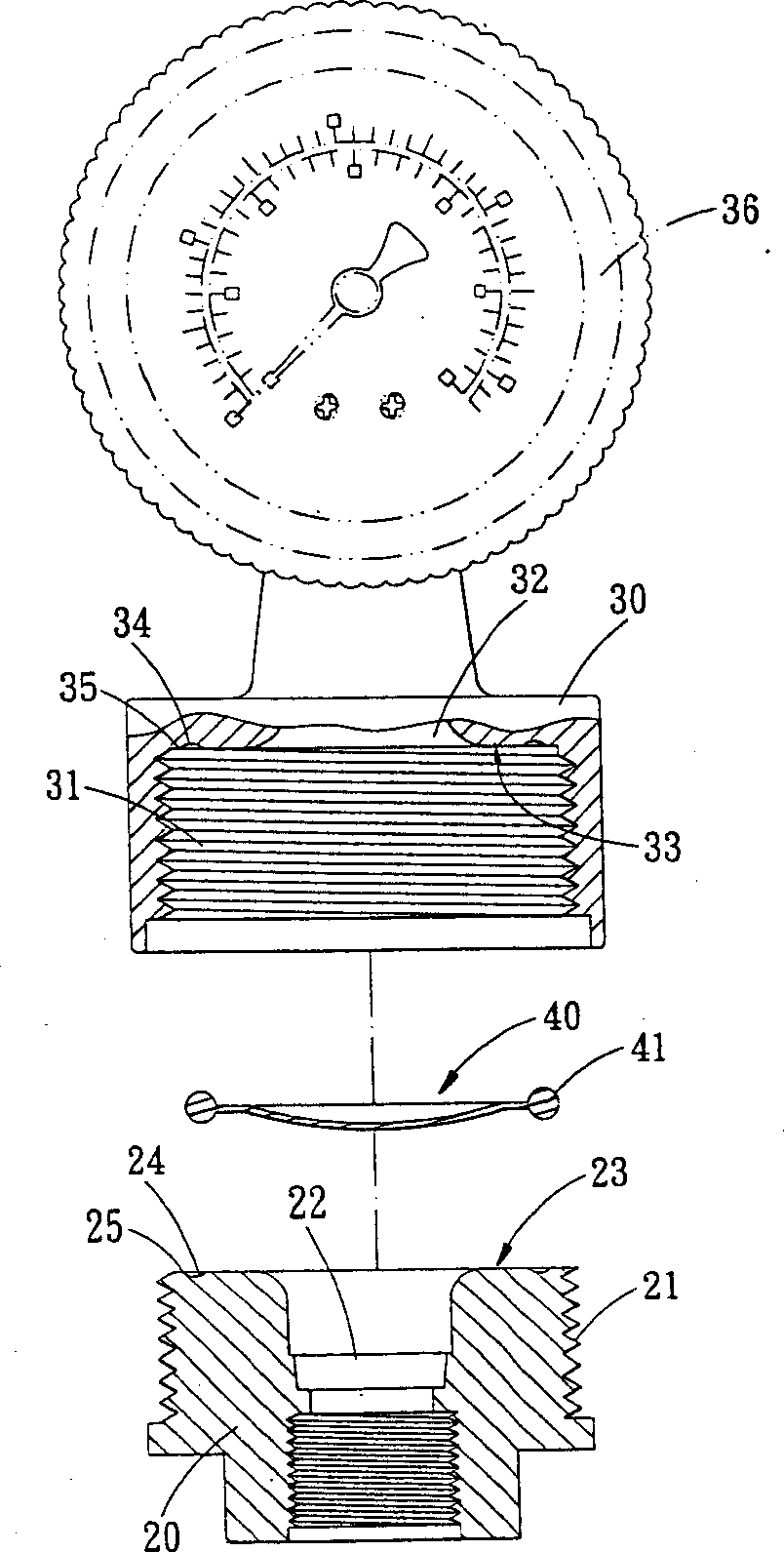

[0015] Such as image 3 , 4 As shown, the present invention is jointly made up of components such as a table seat 20, a table head 30 and a diaphragm 40, wherein:

[0016] The watch seat 20 is a tubular seat body provided with an external thread 21 and a hollow inner diameter 22 . One end of the table base 20 is provided with a setting surface 23, and an annular arc groove 24 is opened on the setting surface 23, and the annular arc groove 24 is connected to the table base 20 by using a smooth arc angle 25 on the peripheral edge. The setting surface 23.

[0017] The meter head 30 is a pipe body provided with an internal thread 31 , a hollow inner diameter 32 and a measuring member 36 . The hollow inner diameter 32 is connected with its measuring member 36, the inner thread 31 corresponds to the outer thread 21 of the watch base 20, and the hollow inner diameter 32 corresponds to the hollow inner diameter 22 of the watch base 20. One end of the watch base 20 is formed with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com