Adjustable probe

A technology of trigger probe and measuring contact, which is applied in the direction of point coordinate measurement, measuring device, instrument, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

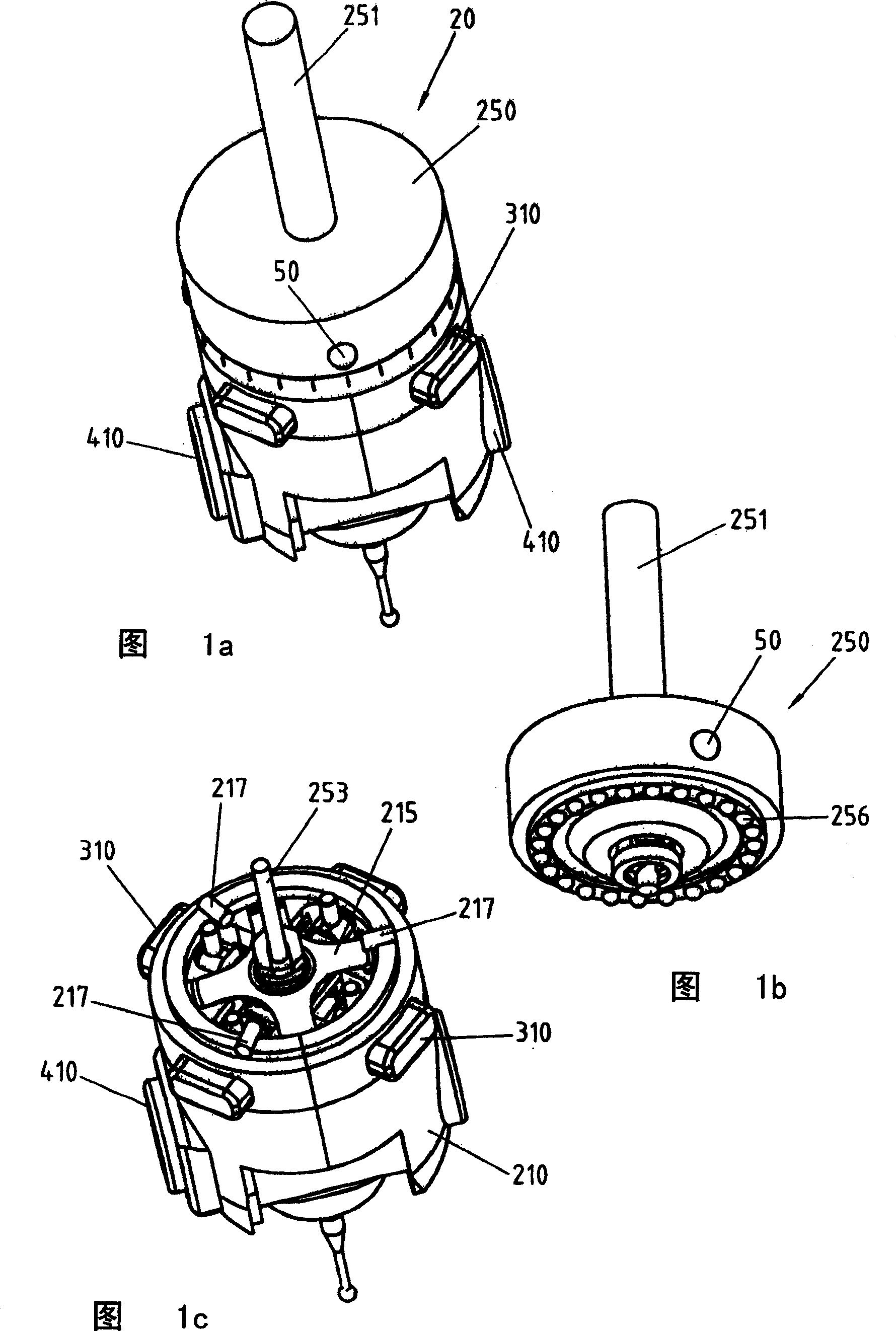

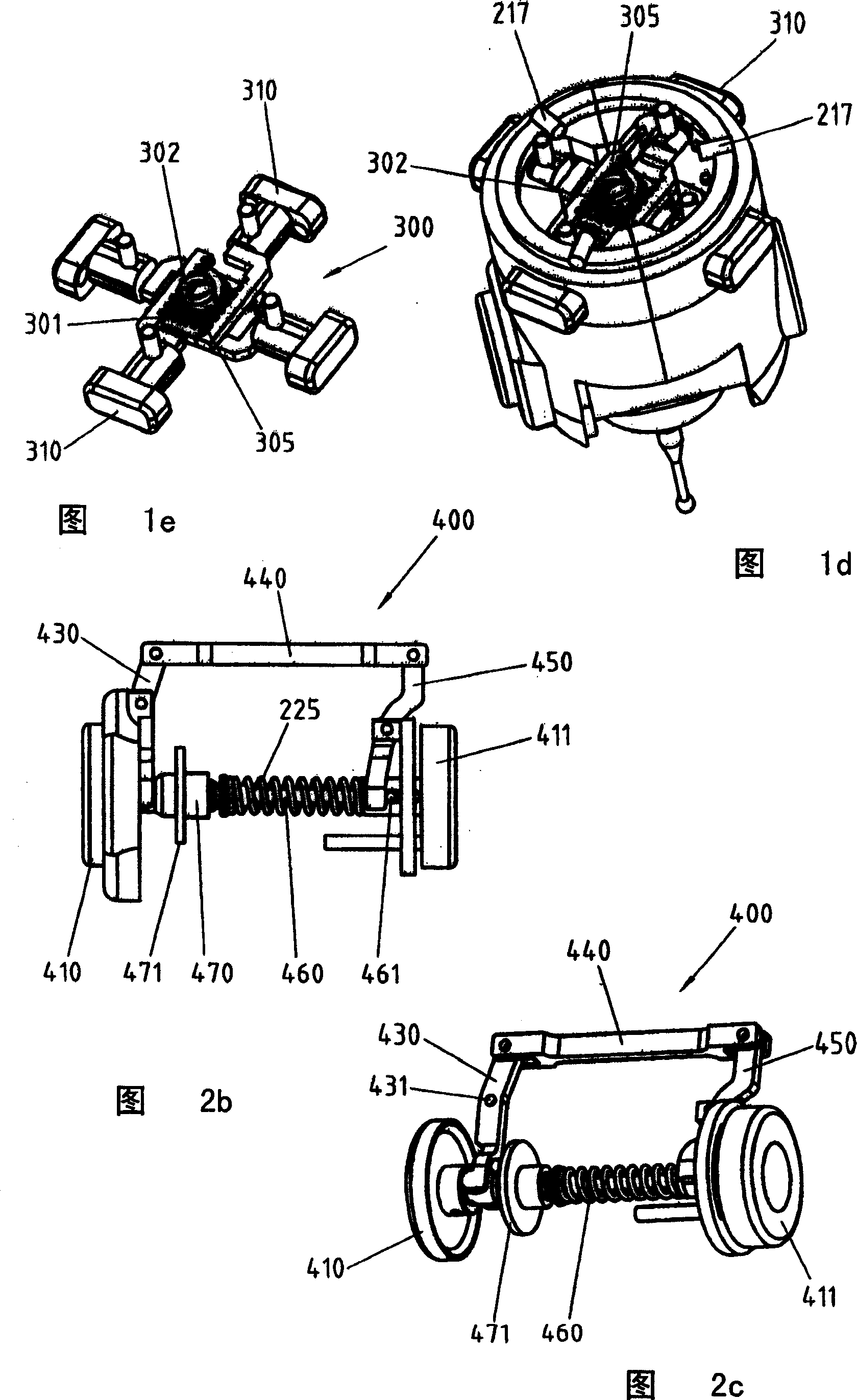

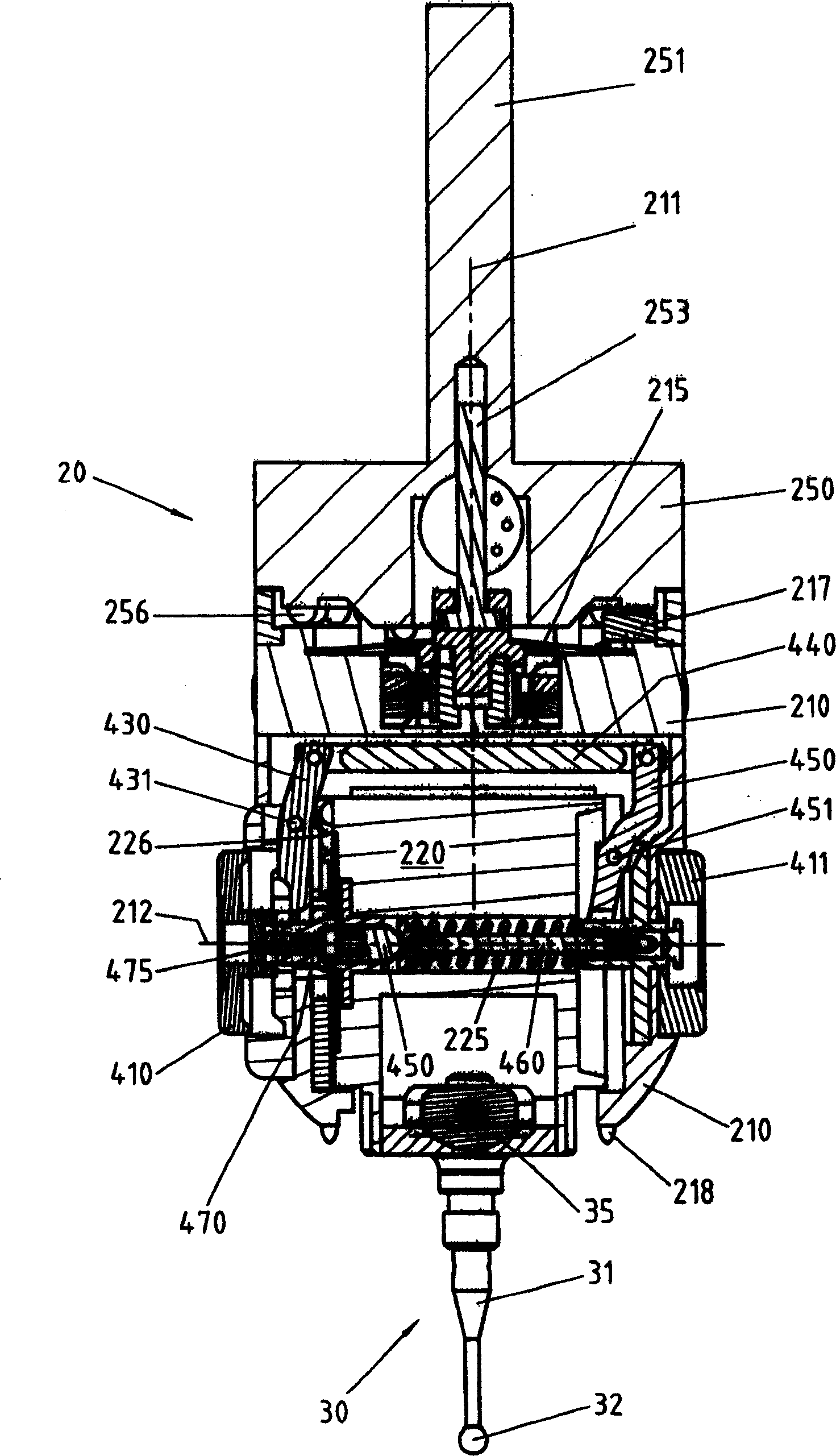

[0021] The first embodiment of the invention shown in Figures 1a-1e is a touch trigger probe 20 comprising a fixed part 250 shown in detail in Figure 1b, designed to be fastened by a threaded rod 251 or any other known fastening means On the moving arm of the measuring machine.

[0022] The fixing part 250 carries on its underside 24 balls 256 which are uniformly distributed in the circumferential direction and partly protrude downwards. Ball 256 defines 24 indexed positions spaced at 15 degree intervals about the first axis of rotation of the probe, as further described below. It is evident that different numbers of spheres can be used depending on the number of indexing positions required.

[0023] The moving element 20 shown in FIGS. 1c and 1d carries three cylindrical pins 217 on its upper side. A flat spring 215 presses the moving element 210 against the fixed element 250 . In this case, each pin 217 rests on two spheres 256 , thus creating six points of contact that d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com