High-speed mezzanine connector

A technology of central connectors and connectors, which is applied in the direction of connections, components of connecting devices, contact parts, etc., can solve the problem of increasing the overall size of the connector structure, increasing the size of the connector, and failing to reduce the size of the connector, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

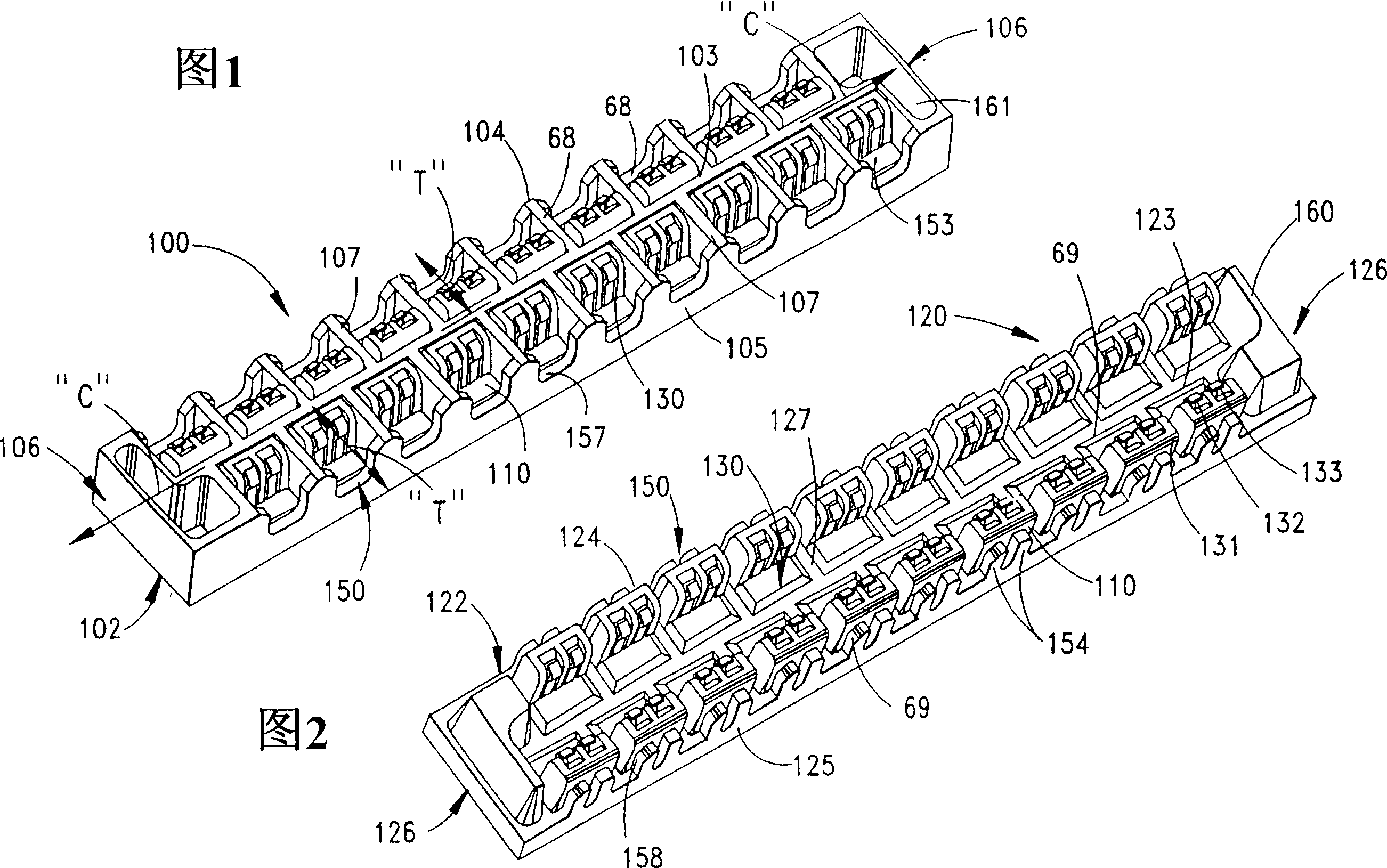

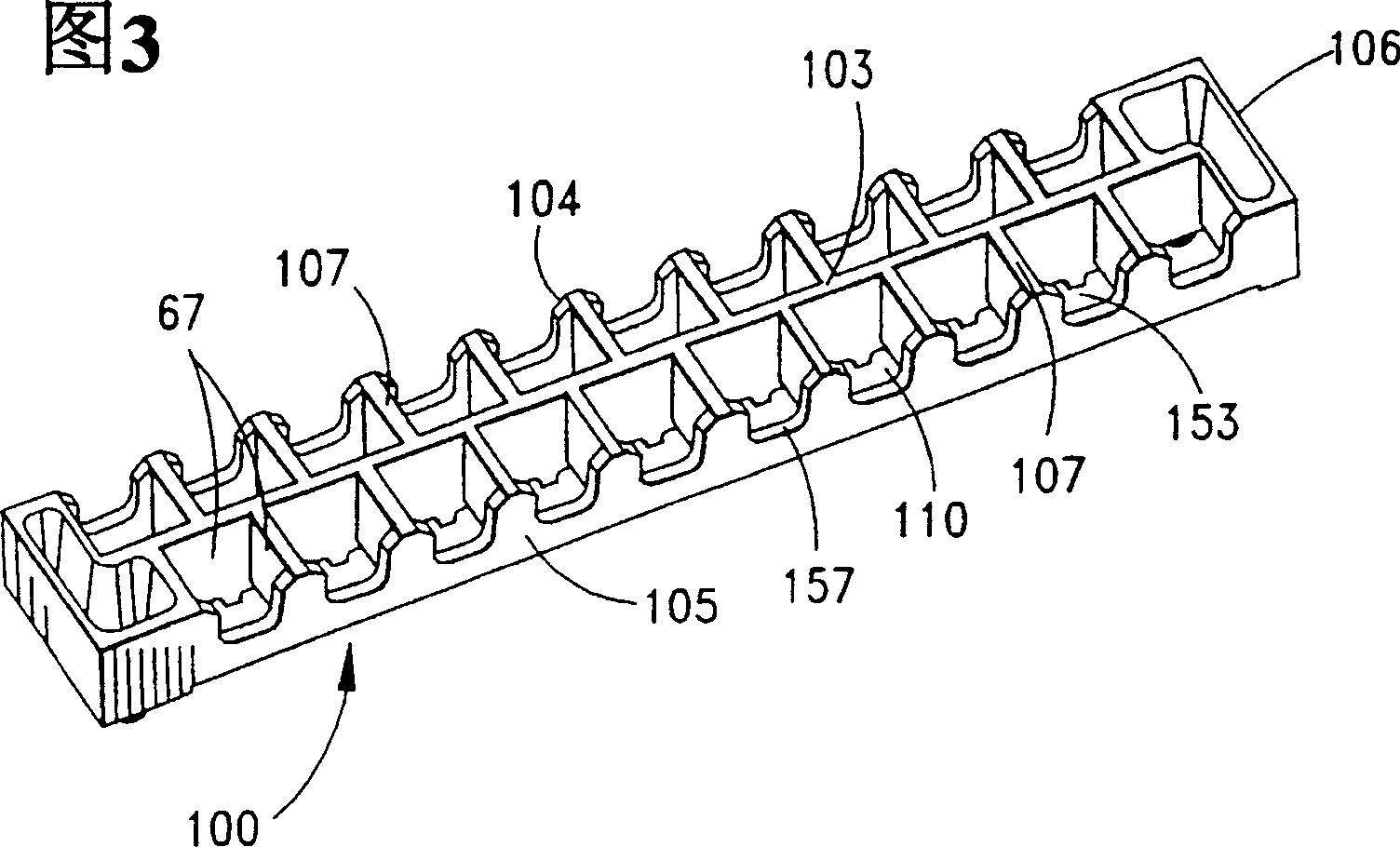

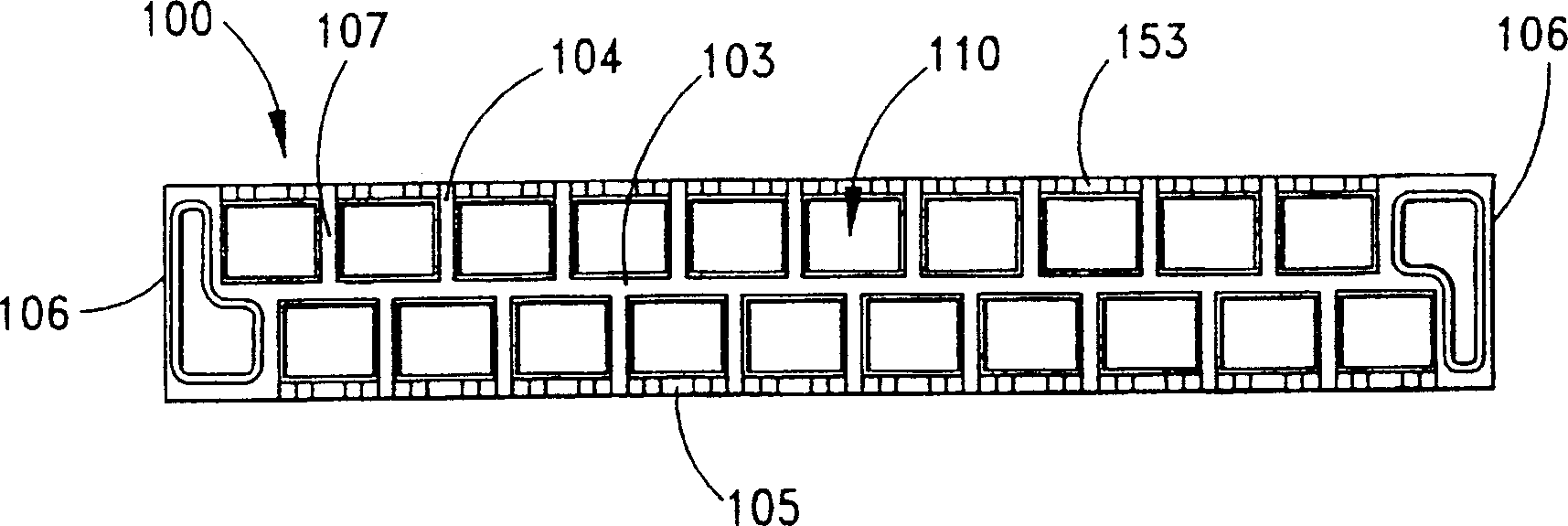

[0068] Figure 1 shows a receptacle connector assembly 100 and Figure 2 shows a plug connector assembly 120, both constructed in accordance with the principles of the present invention. Each assembly includes an insulating housing 102 , 122 . Each housing has a respective central wall 103, 123 extending substantially the entire length of the connector housing, and a pair of side walls 104, 105 and 124, 125. These walls terminate at the ends 106, 126 of the connector assembly. A plurality of spacer walls 107, 127 extend laterally from the central wall 103, 123 to the side walls and, together with the central and side walls of the connector assembly, form a plurality of cavities or openings 110 distributed longitudinally along the connector housing. As shown in Figures 1-5, these cavities 110 are staggered relative to each other on both sides of the longitudinal centerline C of the connector assembly, that is, the transverse centerline T of the cavity on one side of the center w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com