Control apparatus for button sewing machine and button sewing method using the same

The technology of a button sewing machine and a control device is applied to the control device of the button sewing machine and the button field of the button sewing machine, and can solve the problems of reducing the quality of the button sewing products and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Next, specific embodiments of the present invention will be described with reference to the drawings. However, the scope of the invention is not limited to the illustrated examples.

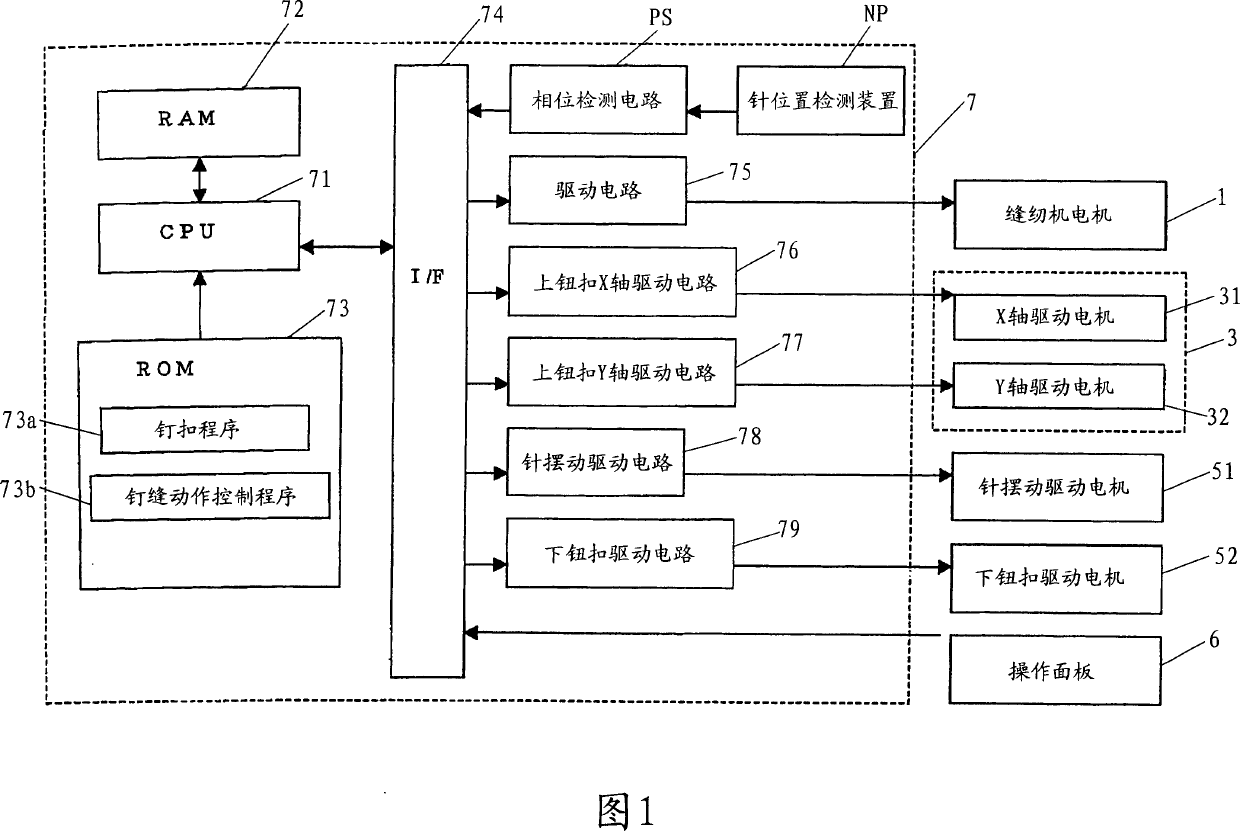

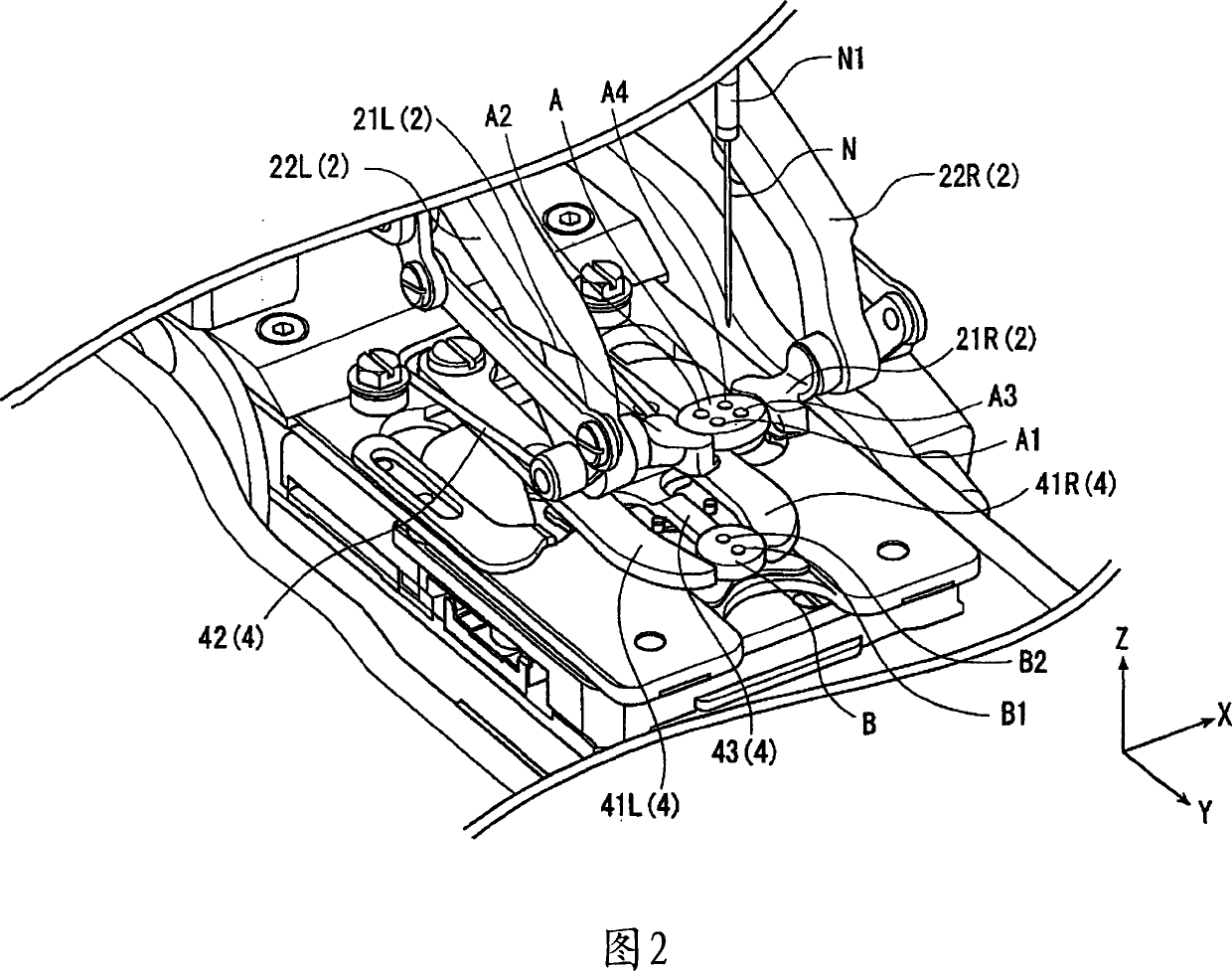

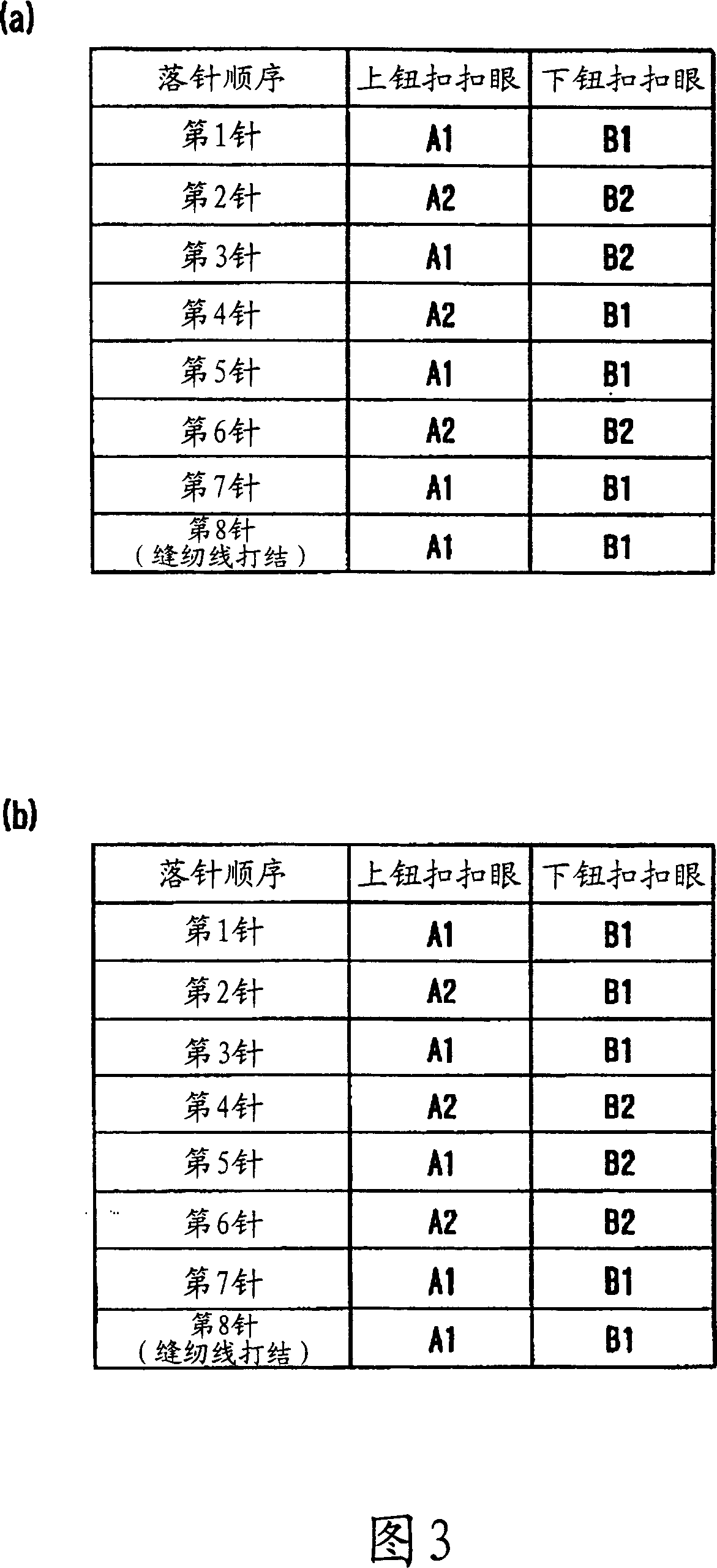

[0042] As shown in FIG. 1 , the button sewing machine 100 is configured to have a button that can be driven in the vertical direction to sew an upper button A (see FIG. 2 ) and a lower button B (see FIG. 2 ) on a cloth M (see FIG. 2 ). 4) The sewing machine motor 1 of the upper sewing needle N (refer to FIG. 2 ); the needle swing motor 51 that can drive the sewing needle N in the left-right direction (needle swing direction); can be driven in the front-back direction and left-right direction for holding the button The upper button holding mechanism driving device (driving device) 3 of the upper button holding part 2 (referring to Fig. 2 ) of A; the lower button holding mechanism 4 (referring to Fig. 2 ) for holding the lower button B can be driven in the front and rear direction ) of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com