Self-tightening type drill chuck in modified structure

An improved structure and drill chuck technology, which is applied in the mechanical field, can solve problems such as complex structure and insufficient reliability, and achieve the effect of loosening and labor saving, simple and reasonable structure, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

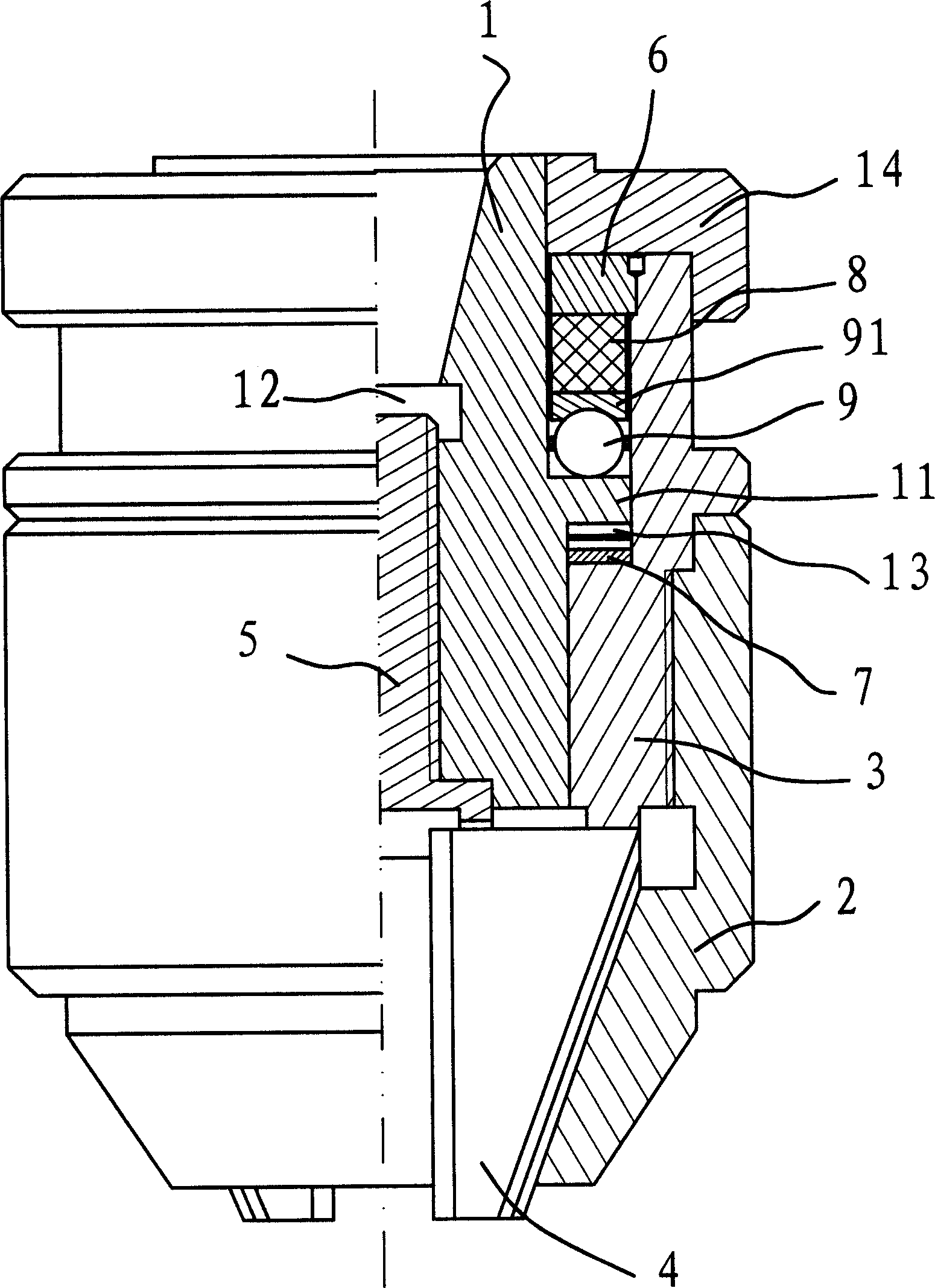

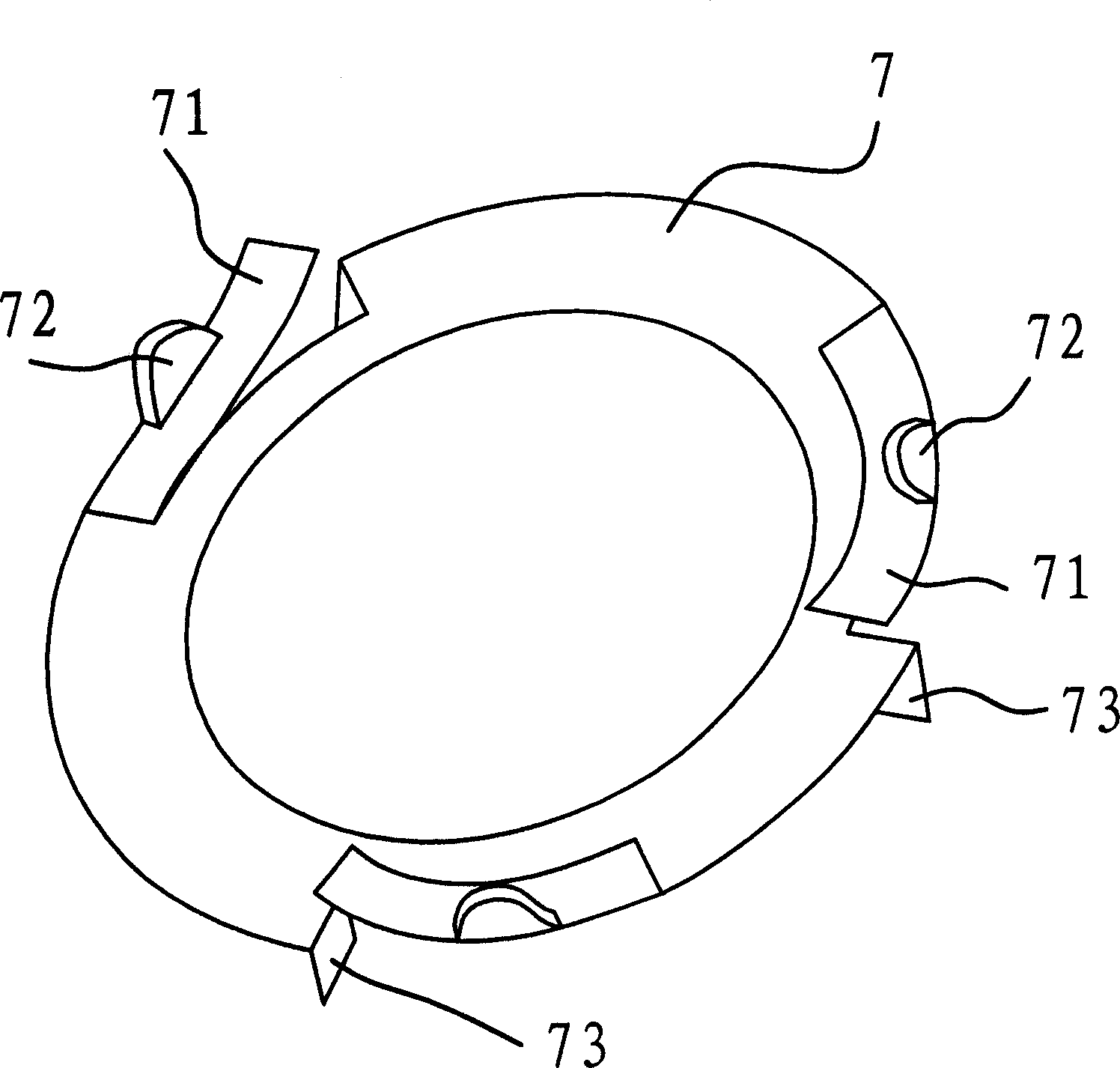

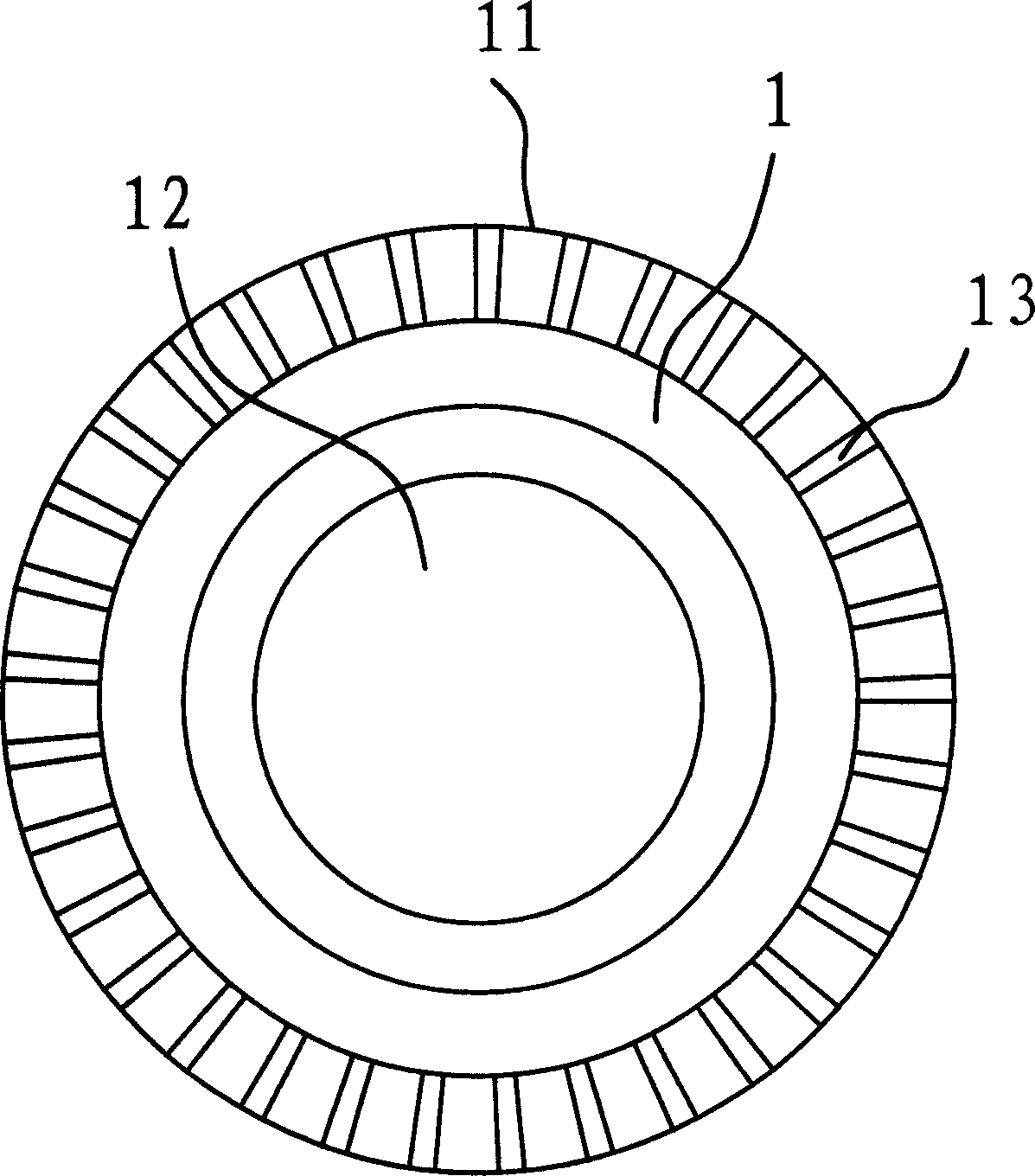

[0018] Such as figure 1 As shown, the self-tightening drill chuck of the improved structure includes the main body of the drill chuck 1, the ball cover 6, the clamping jaw seat 3, the self-tightening screw 5, the clamping jaw 4, the outer cover 2 and other parts. The main body 1 has an approximately cylindrical structure with a through hole 12 in the center, and the self-tightening screw 5 is connected with the main body 1 through threads. In the process of rotating the main body 1, if the self-tightening screw 5 does not rotate, it will stretch up and down along the main body 1.

[0019] The clamping jaw seat 3 is sleeved outside the main body 1. There is a ball cover 6 on the upper part of the jaw seat 3. The ball cover 6 is fixed on the inner side of the jaw seat 3. The ball cover 6 restricts the main body 1 in the jaw seat 3. The outer casing 2 is connected with the clamping jaw base 3 through threads.

[0020] Like the ordinary drill chuck, there are three guide grooves on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com