Luminous diode

A technology of light-emitting diodes and surface electrodes, applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problems of reduced transparency, unreliability, discoloration of transparent seals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

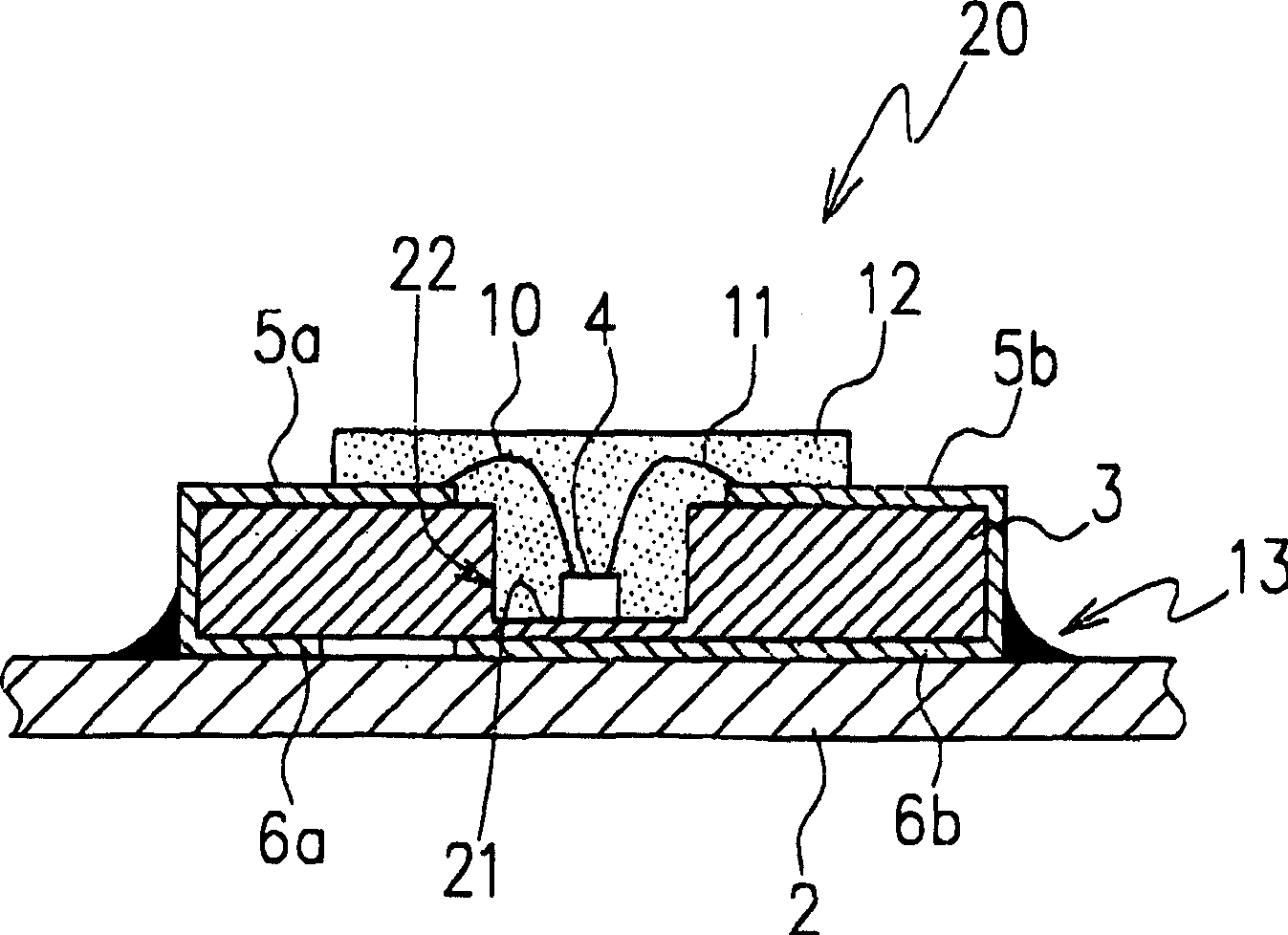

[0019] A preferred embodiment of a light emitting diode according to the present invention will be explained with reference to the accompanying drawings.

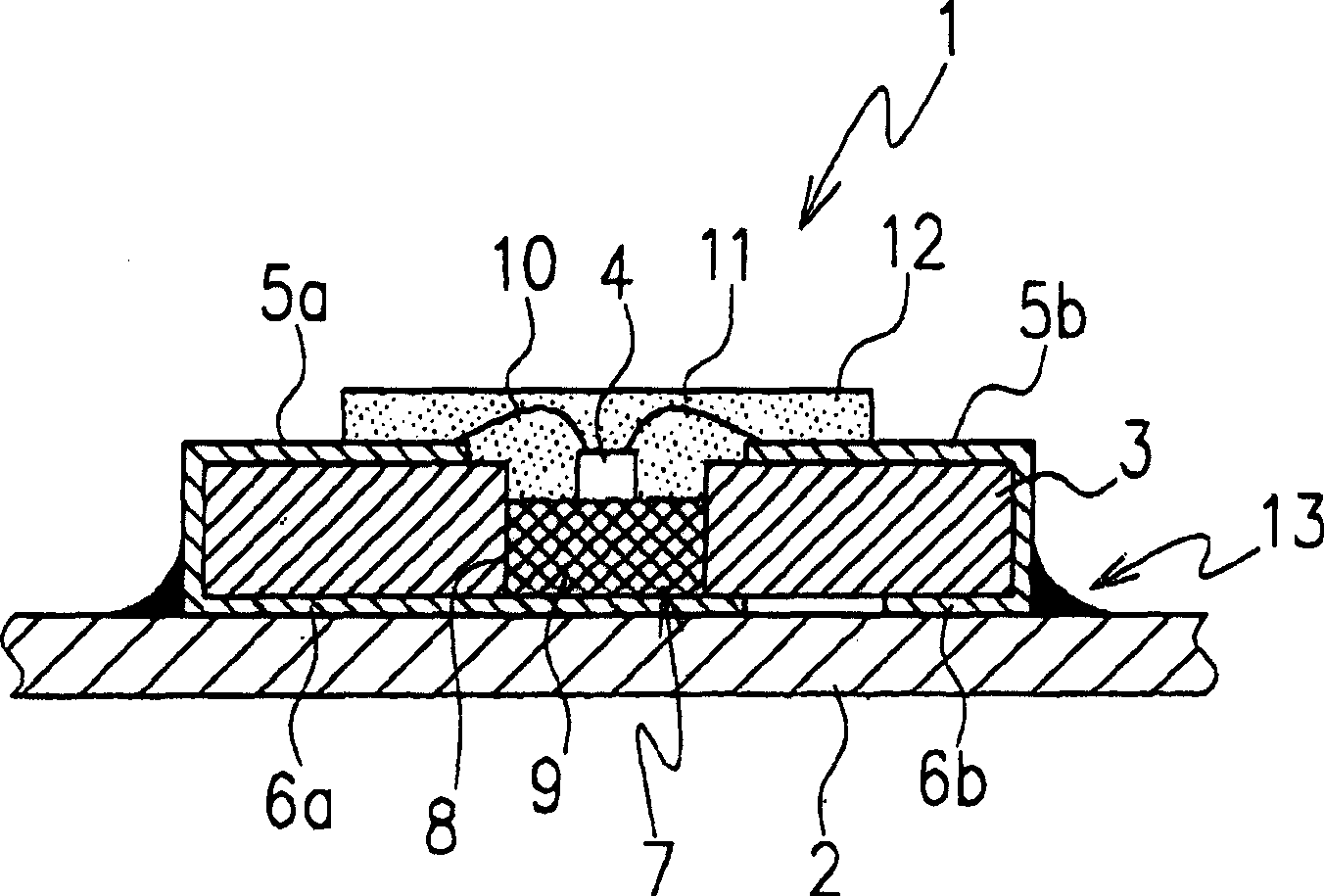

[0020] figure 1 The light emitting diode 1 of the first embodiment of the present invention will be described by way of example.

[0021] The light emitting diode 1 includes an LED chip 4, an insulating circuit substrate 3 in which the LED chip 4 is placed, and a printed wiring board 2. The insulating circuit substrate 3 is made of glass epoxy, silicone or the like.

[0022] Provided on the circuit substrate 3 are a pair of integrally formed upper and lower surface electrodes 5a, 6a and 5b, 6b.

[0023] The circuit substrate 3 has a heat radiation mechanism 7 . Radiation mechanism 7 comprises a heat radiation part 9, and it is in figure 1 is arranged in the storage portion 8 formed in the substantially central portion of the circuit substrate 3 in the embodiment shown in . The storage portion 8 includes, for example, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com