CD machine

A technology for optical disc drives and optical discs, which is applied to instruments, record carrier structural parts, and reduction of physical parameters of carriers, etc., can solve problems such as weight increase and overall size increase of notebook PCs, avoid heat accumulation, and achieve excellent heat release characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

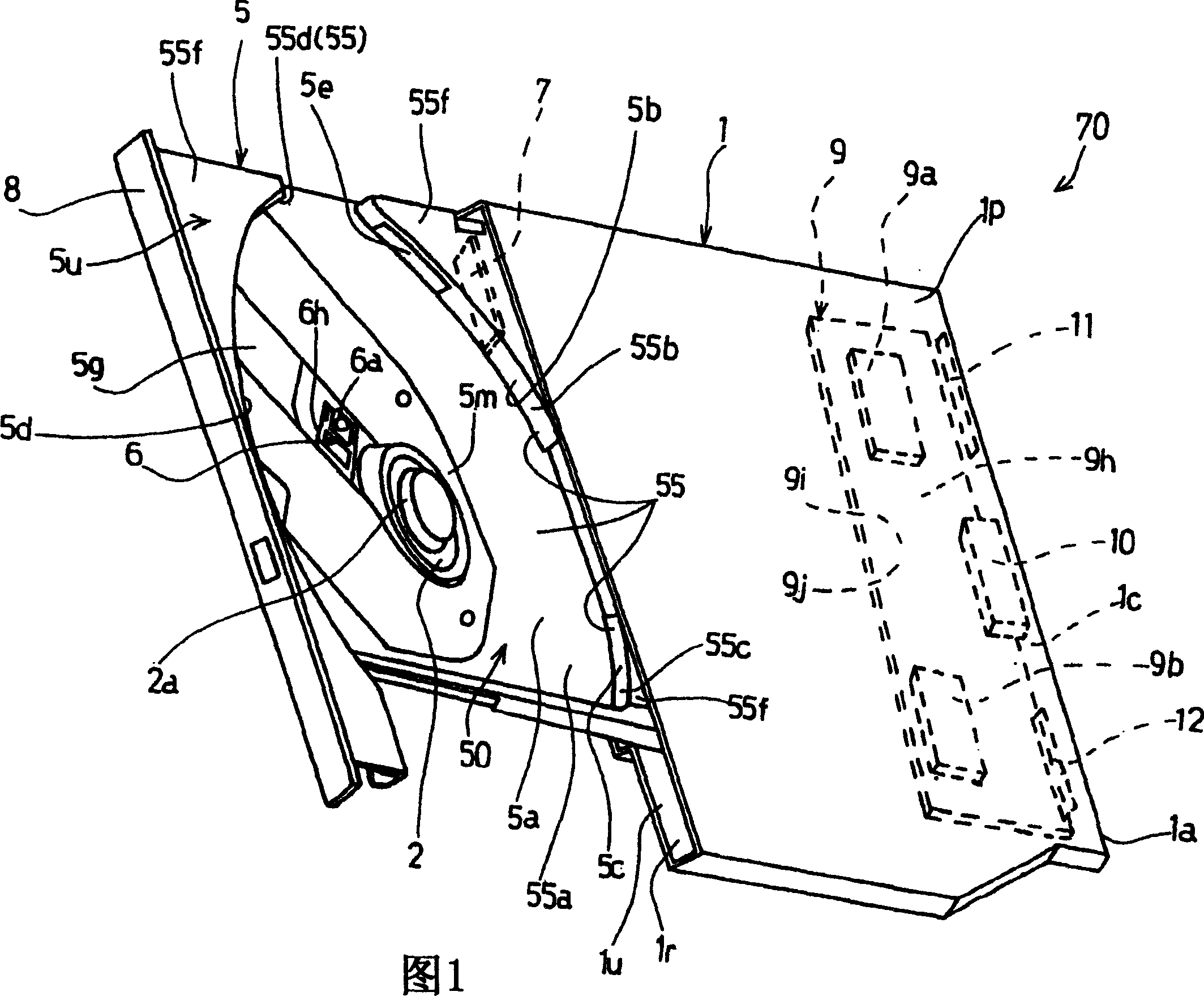

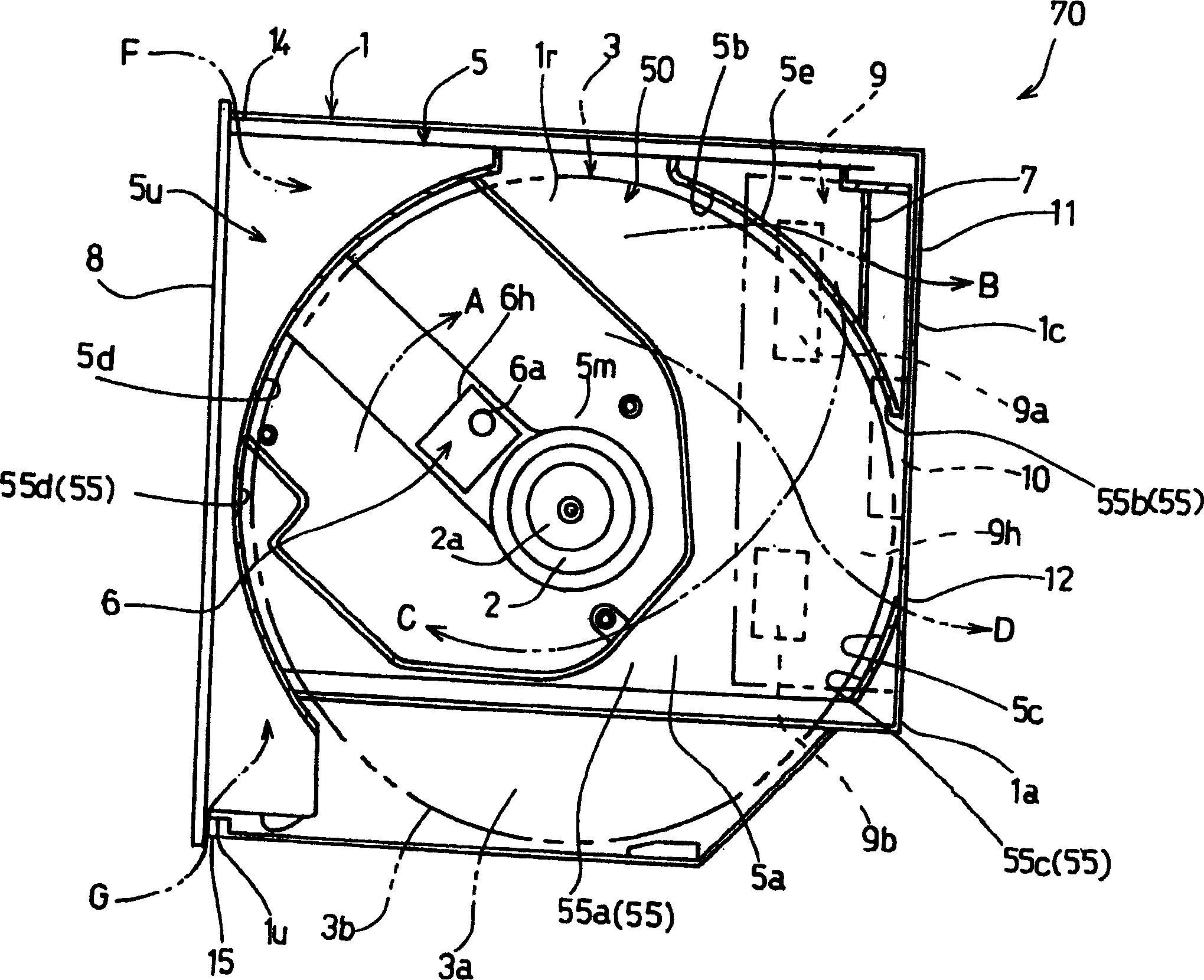

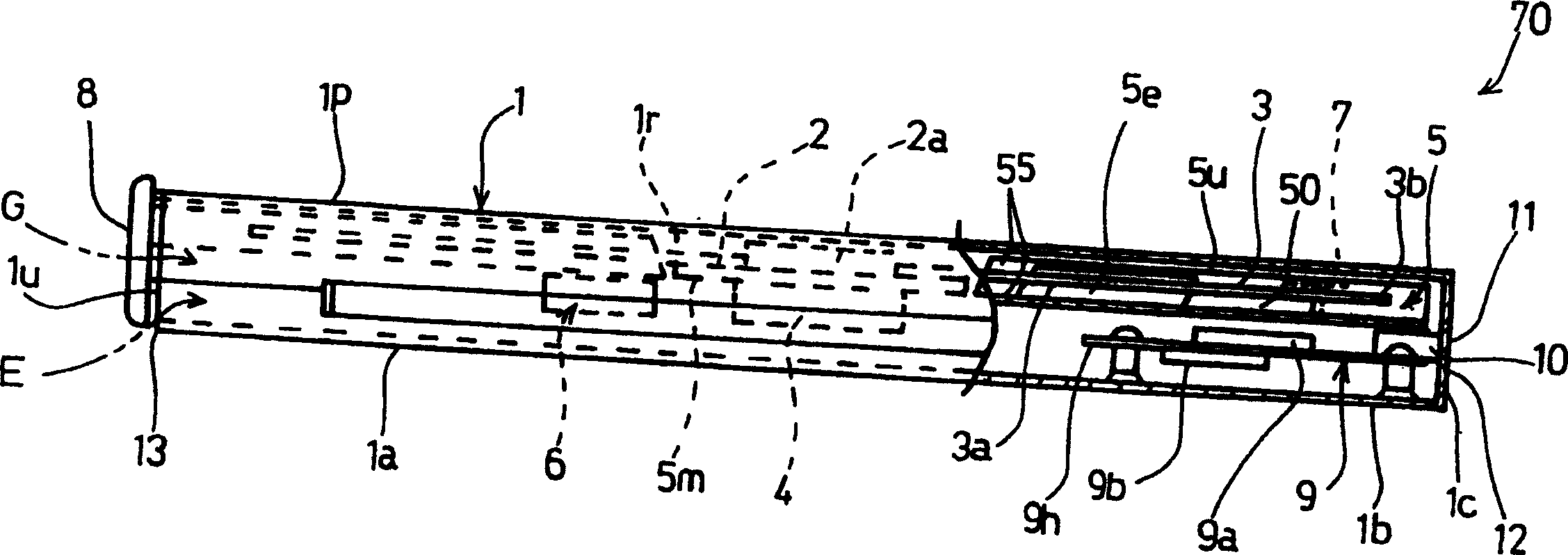

[0054] An embodiment of the optical disk drive of the present invention will be described below with reference to the accompanying drawings.

[0055] FIG. 1 is a perspective view showing an embodiment of an optical disc player of the present invention, figure 2 It is an explanatory diagram showing the state in which the tray is received inside the main body of the optical disc drive, image 3 It is an explanatory diagram showing the state that a part of the optical disc drive was removed, Figure 4 for image 3 An enlarged view of the main part of . Each figure will be specifically described below, and FIG. 1 is a perspective view showing a state in which a tray 5 in an optical disc drive 70 is ejected from the optical disc drive 1 . in addition, figure 2 It is a plan sectional view of main parts showing a state in which the tray 5 of FIG. 1 is inserted into the operating position of the main body 1 of the disc player. in addition, image 3 for viewing from the side fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com