Hard alloy taking nickel-aluminum intermetallic compound Ni3Al as binding phase and preparation method thereof

A technology of cemented carbide and aluminum metal, which is applied in the field of cemented carbide materials and its preparation, can solve problems such as uneven microstructure of alloys, coarse pre-alloyed powder, and influence on mechanical properties, and achieve good uniformity, high brittleness, and high composition uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

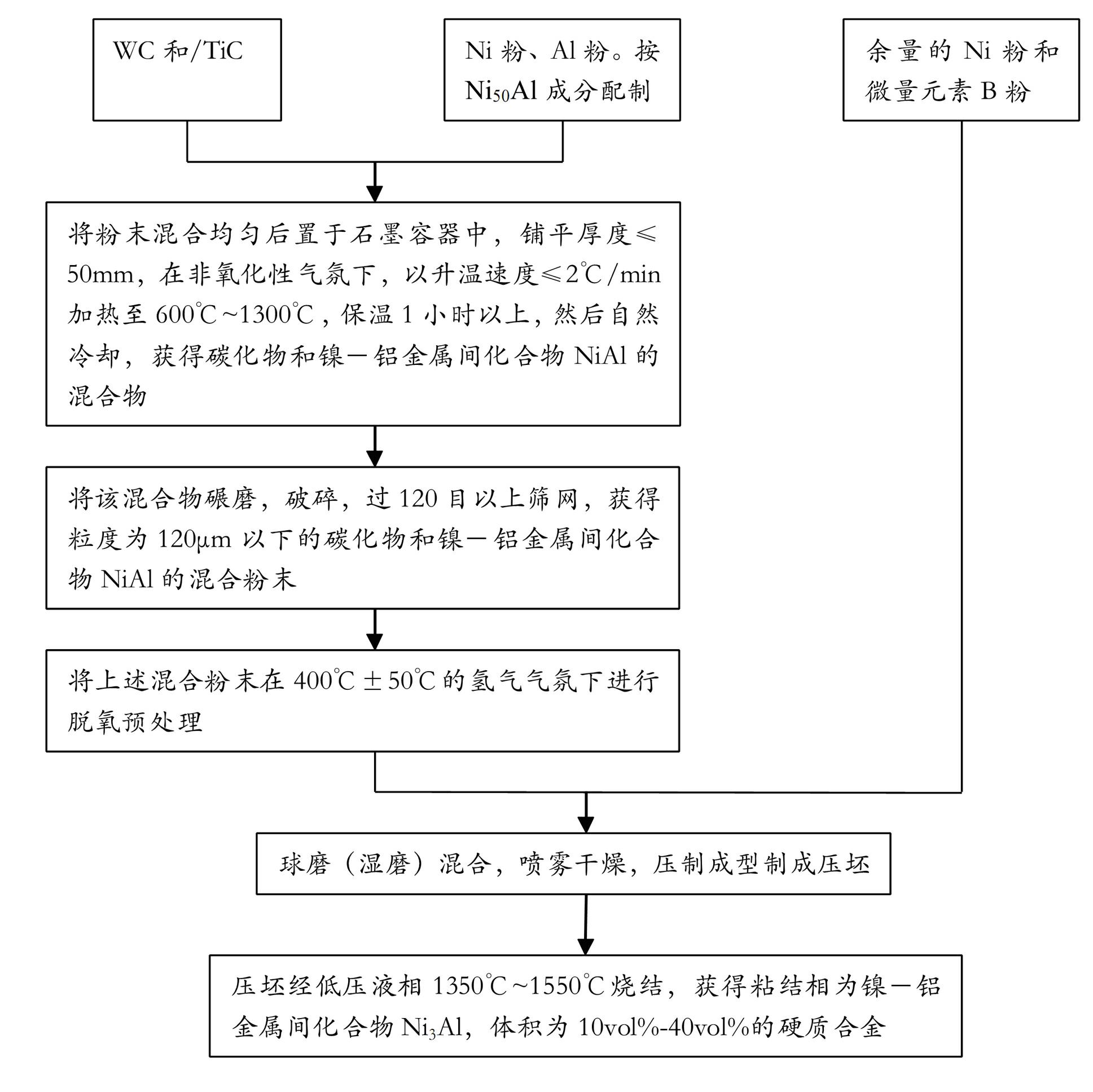

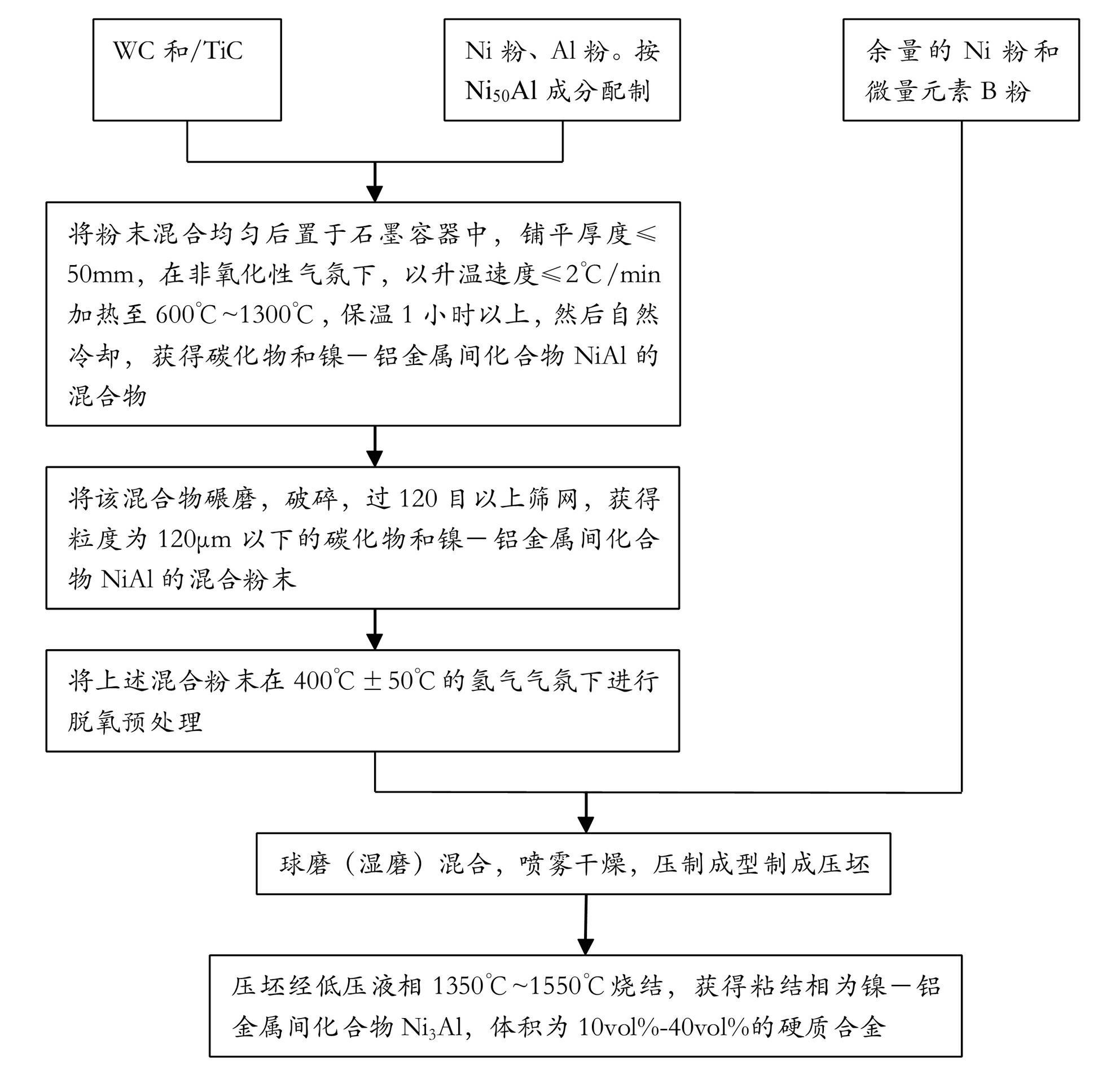

[0022] Embodiment 1: According to figure 1 The flow shown, press Ni 50 The composition ratio of Al is that the mass percentage is 2.09% nickel powder and aluminum powder, and mix evenly with the remaining tungsten carbide powder; the above-mentioned mixed powder is placed in a graphite container and paved with a thickness of 50mm. Heat up to 600°C at a heating rate of ℃ / min, keep it warm for 4 hours, and then cool naturally to obtain a mixture of tungsten carbide and nickel-aluminum intermetallic compound NiAl; grind the mixture, crush it, and pass it through a 250-mesh sieve to obtain a particle size of 58 μm The following mixed powder of tungsten carbide and nickel-aluminum intermetallic compound NiAl; the above-mentioned mixed powder of tungsten carbide and nickel-aluminum intermetallic compound NiAl is subjected to deoxidation pretreatment in a hydrogen atmosphere at 400°C±50°C; then, The mass percentage is 3.01% of Ni powder and 0.0025% of B powder and the balance of the...

Embodiment 2

[0023] Embodiment 2: According to figure 1 The flow shown, press Ni 50 The composition ratio of Al is that the mass percentage is 4.58% nickel powder and aluminum powder, and the balance of tungsten carbide powder is mixed evenly; the above-mentioned mixed powder is placed in a graphite container and paved with a thickness of 30mm. Under a non-oxidizing atmosphere, 1 Heat up to 900°C at a heating rate of ℃ / min, keep it warm for 3 hours, and then cool naturally to obtain a mixture of tungsten carbide and nickel-aluminum intermetallic compound NiAl; grind the mixture, crush it, and pass it through a 200-mesh sieve to obtain a particle size of 75 μm The following mixed powder of tungsten carbide and nickel-aluminum intermetallic compound NiAl; the above-mentioned mixed powder of tungsten carbide and nickel-aluminum intermetallic compound NiAl is subjected to deoxidation pretreatment in a hydrogen atmosphere at 400°C±50°C; then, The mass percentage of 6.38% of Ni powder and 0.005...

Embodiment 3

[0024] Embodiment 3: According to figure 1 The flow shown, press Ni 50 The composition ratio of Al is that the mass percentage is 7.61% nickel powder and aluminum powder, and the balance of tungsten carbide powder is mixed evenly; the above-mentioned mixed powder is placed in a graphite container and paved with a thickness of 20mm. Under a non-oxidizing atmosphere, 1 Heat up to 1100°C at a heating rate of ℃ / min, keep it warm for 2 hours, and then cool naturally to obtain a mixture of tungsten carbide and nickel-aluminum intermetallic compound NiAl; grind the mixture, crush it, and pass it through a 160-mesh sieve to obtain a particle size of 96 μm The following mixed powder of tungsten carbide and nickel-aluminum intermetallic compound NiAl; the above-mentioned mixed powder of tungsten carbide and nickel-aluminum intermetallic compound NiAl is subjected to deoxidation pretreatment in a hydrogen atmosphere at 400°C±50°C; then, The mass percentage of 10.15% Ni powder and 0.0085...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com