Light-emitting diode

A technology of light-emitting diodes and plate tubes, applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problems of short working life, unreliability, and reduced luminous brightness of LED chips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A preferred embodiment of a light emitting diode according to the present invention will be explained with reference to the accompanying drawings.

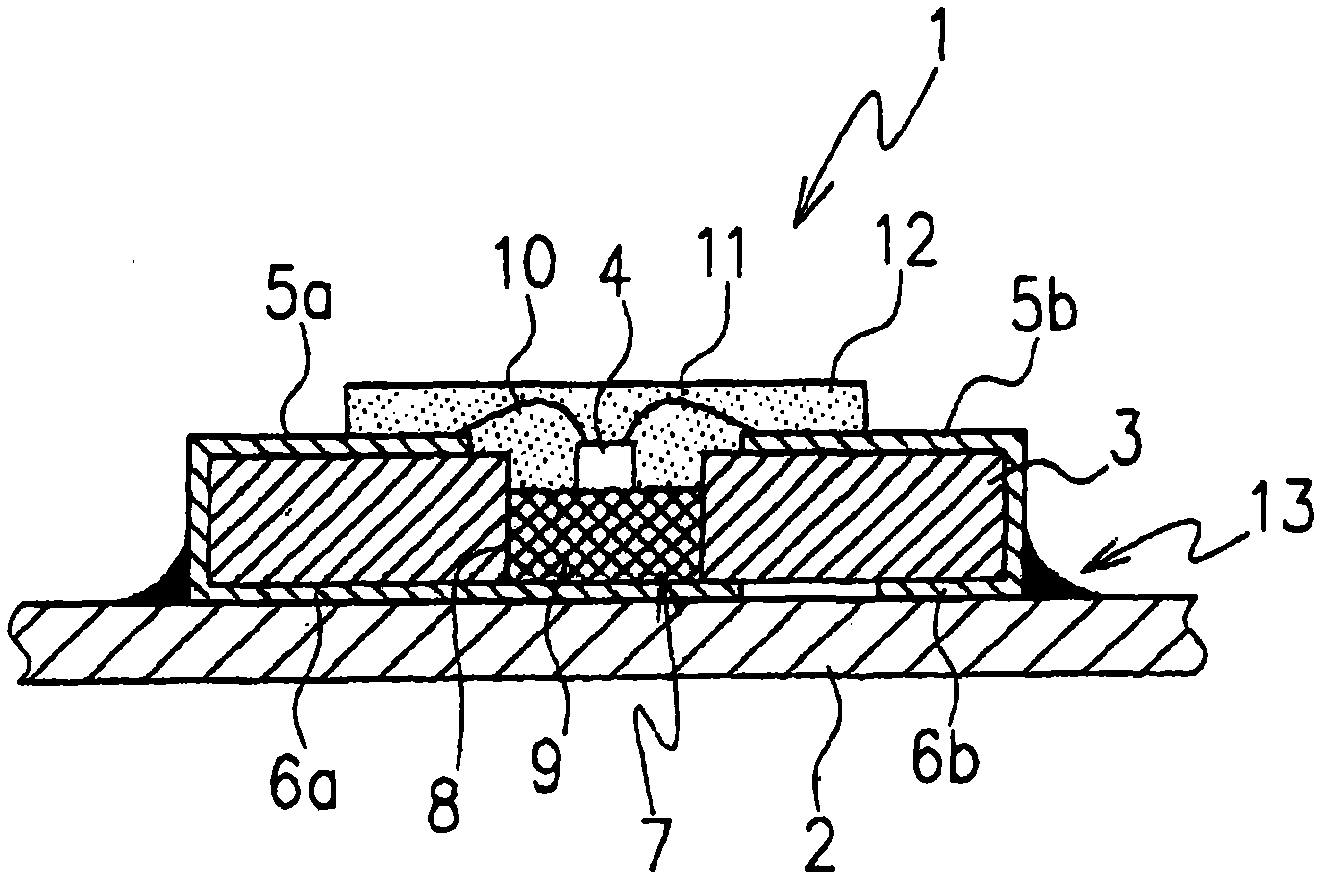

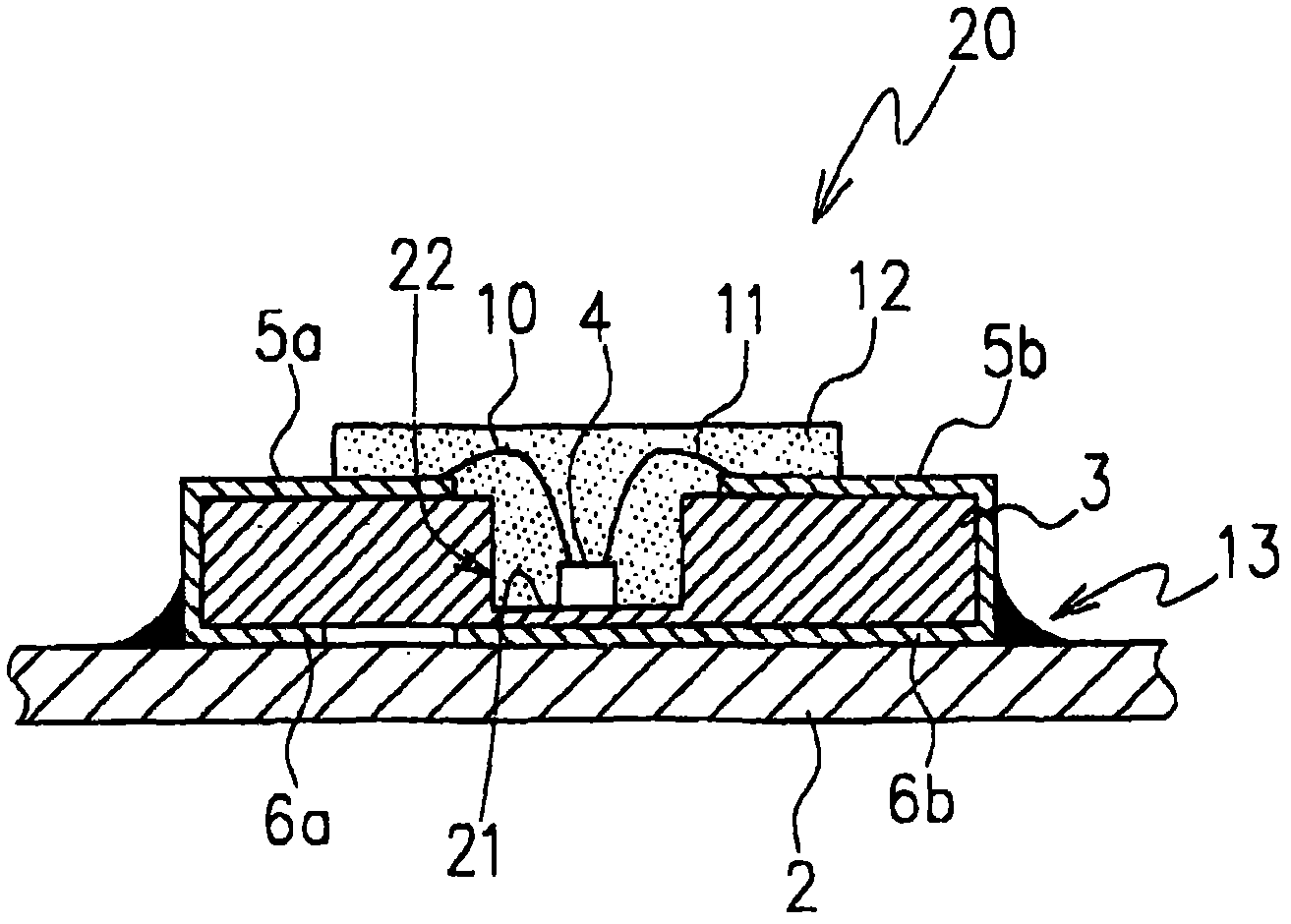

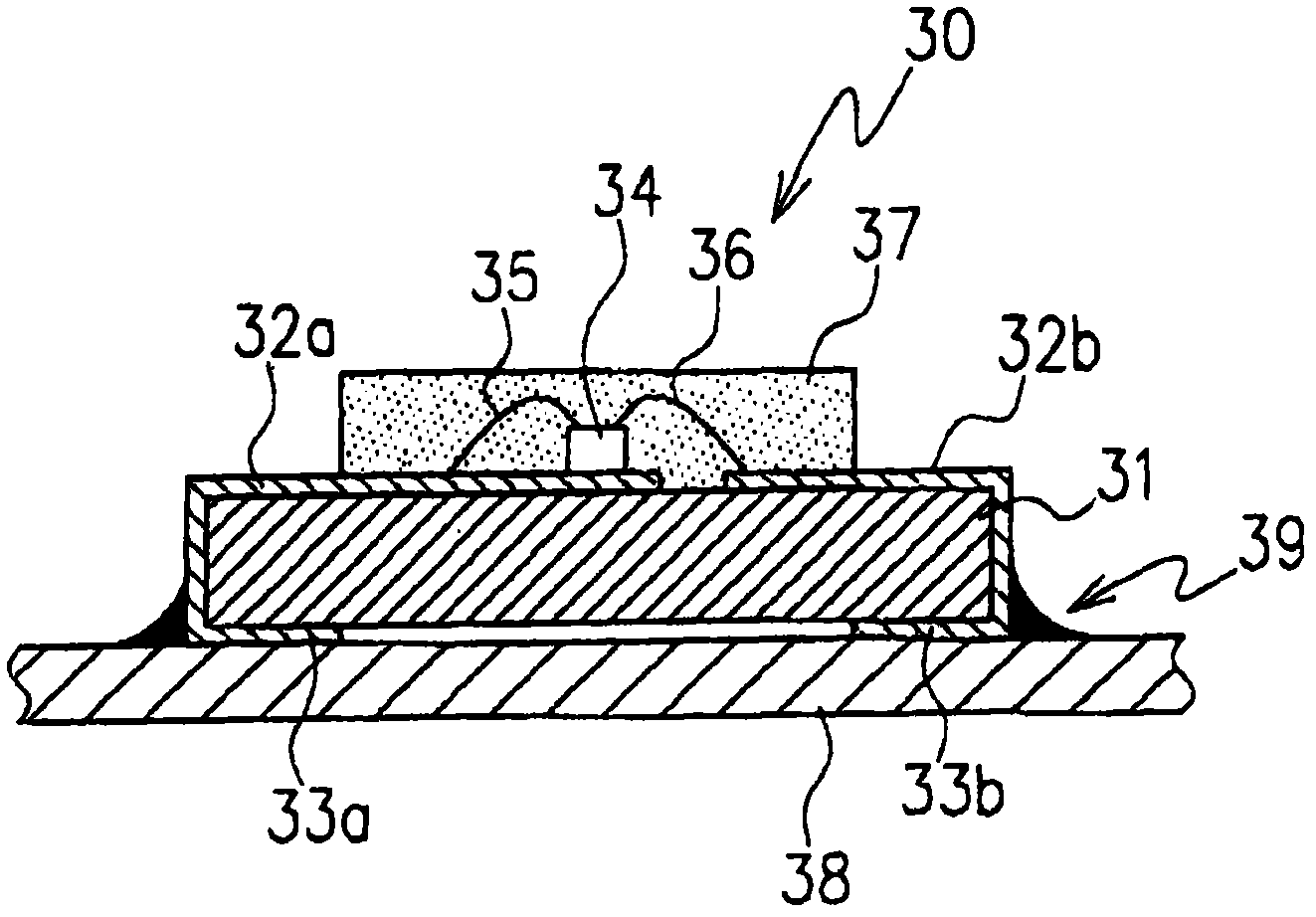

[0017] figure 1 The light emitting diode 1 of the first embodiment of the present invention will be described by way of example.

[0018] The light emitting diode 1 includes an LED chip 4, an insulating circuit substrate 3 in which the LED chip 4 is placed, and a printed wiring board 2. The insulating circuit substrate 3 is made of glass epoxy, silicone or the like.

[0019] Provided on the circuit substrate 3 are a pair of integrally formed upper and lower surface electrodes 5a, 6a and 5b, 6b.

[0020] The circuit substrate 3 has a heat radiating mechanism 7. The radiating mechanism 7 includes a heat radiating part 9, which is figure 1 In the embodiment shown in FIG. When the heat radiation member 9 is inserted in the storage portion 8, the heat radiation member 9 is arranged to contact the surface of the printed wiri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com