Electronic transforming and frequency inverting inducer and electrostatic preserving and defreezing method

A high-voltage frequency conversion and electronic adjustment technology, which is applied in food preparation, food science, application and other directions, can solve the problems of inability to guarantee the quality of frozen items, waste of energy, and delay in the time of misfreezing items.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Reference will now be made in detail to embodiments of the invention, examples of which are illustrated in the accompanying drawings.

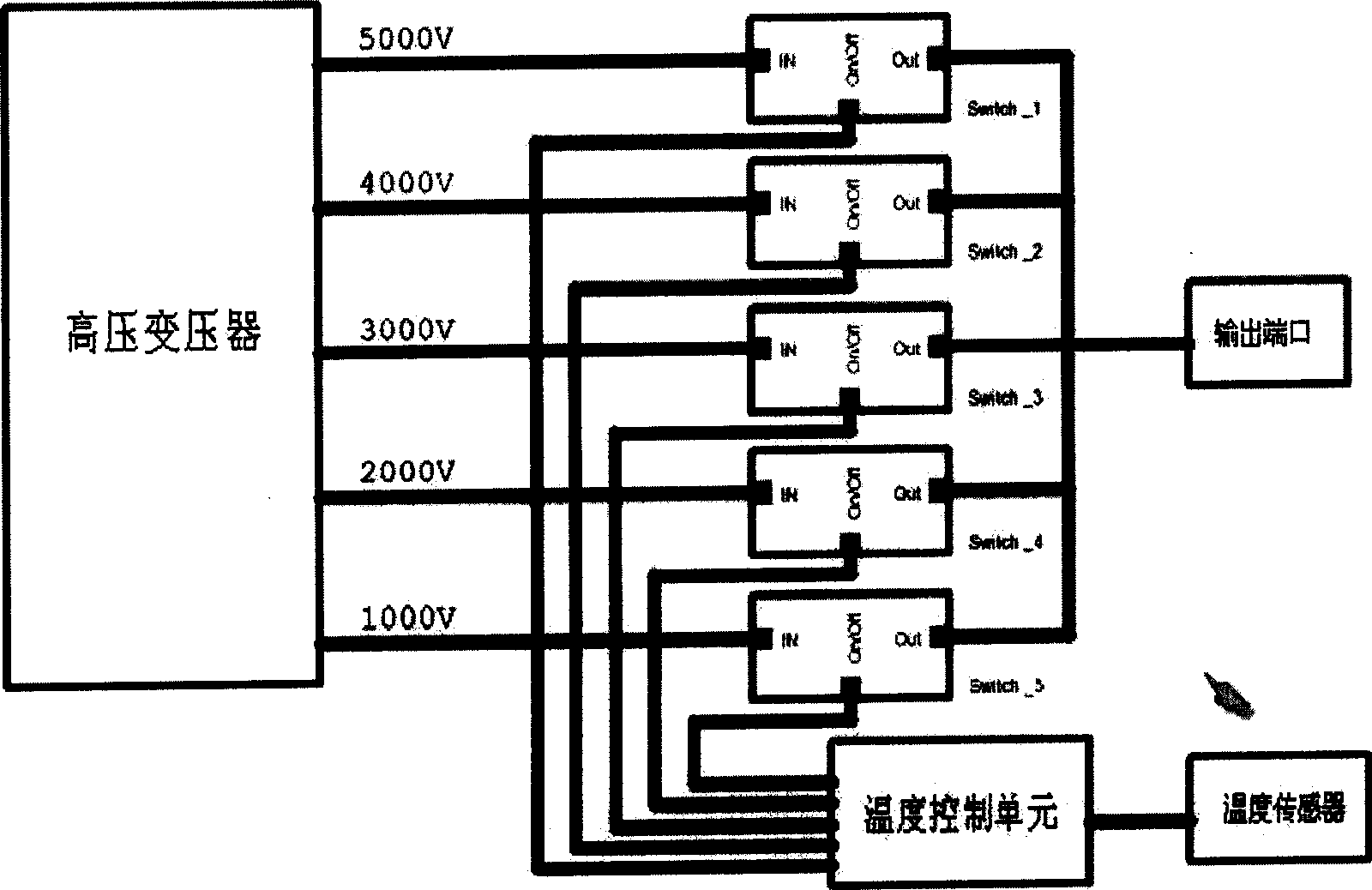

[0037] figure 1 It is an electronic modulation high voltage variable frequency induction device according to the principle of the present invention.

[0038] Such as figure 1 As shown, the electronically modulated high-voltage variable-frequency induction device includes a high-voltage transformer, a plurality of voltage selectors are connected to it, and have voltage output ports. The temperature control unit is connected to each voltage selector respectively. When the temperature sensor transmits the temperature of the detected item to After giving to the temperature control unit, the temperature control unit adjusts different voltage values according to the temperature and outputs them at the output port of the power supply. 1000V, 2000V, 3000V, 4000V and 5000V are given as enumerations only by way of example in the drawings of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com