High temperature self compensatiojn lubrication wear resistance material and its preparing method

A wear-resistant material and self-compensating technology, which is applied in the direction of engine lubrication, mechanical equipment, ceramic products, etc., can solve the problem that the high-temperature volatility of liquid medium cannot meet the requirements of extreme high-temperature work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

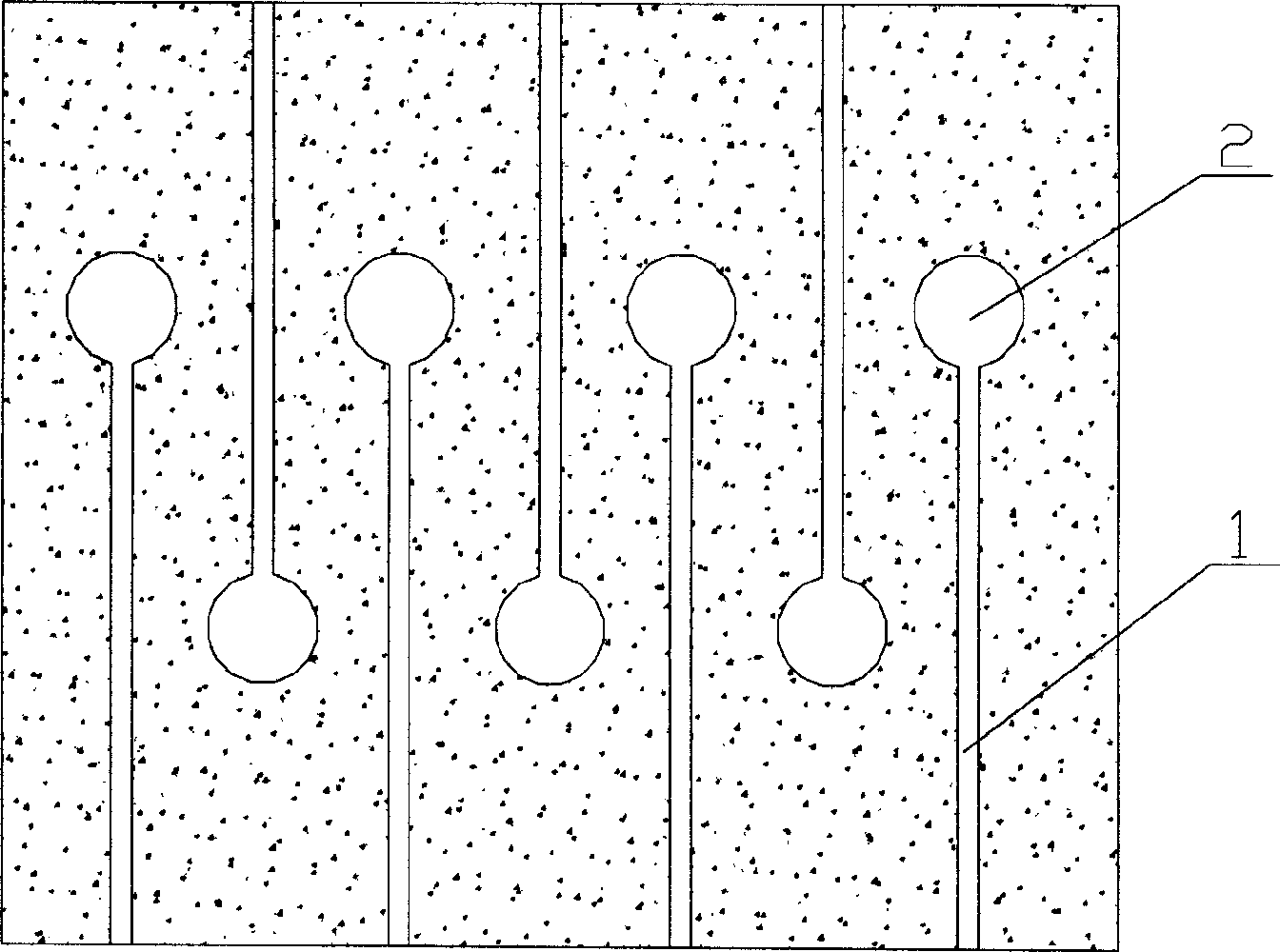

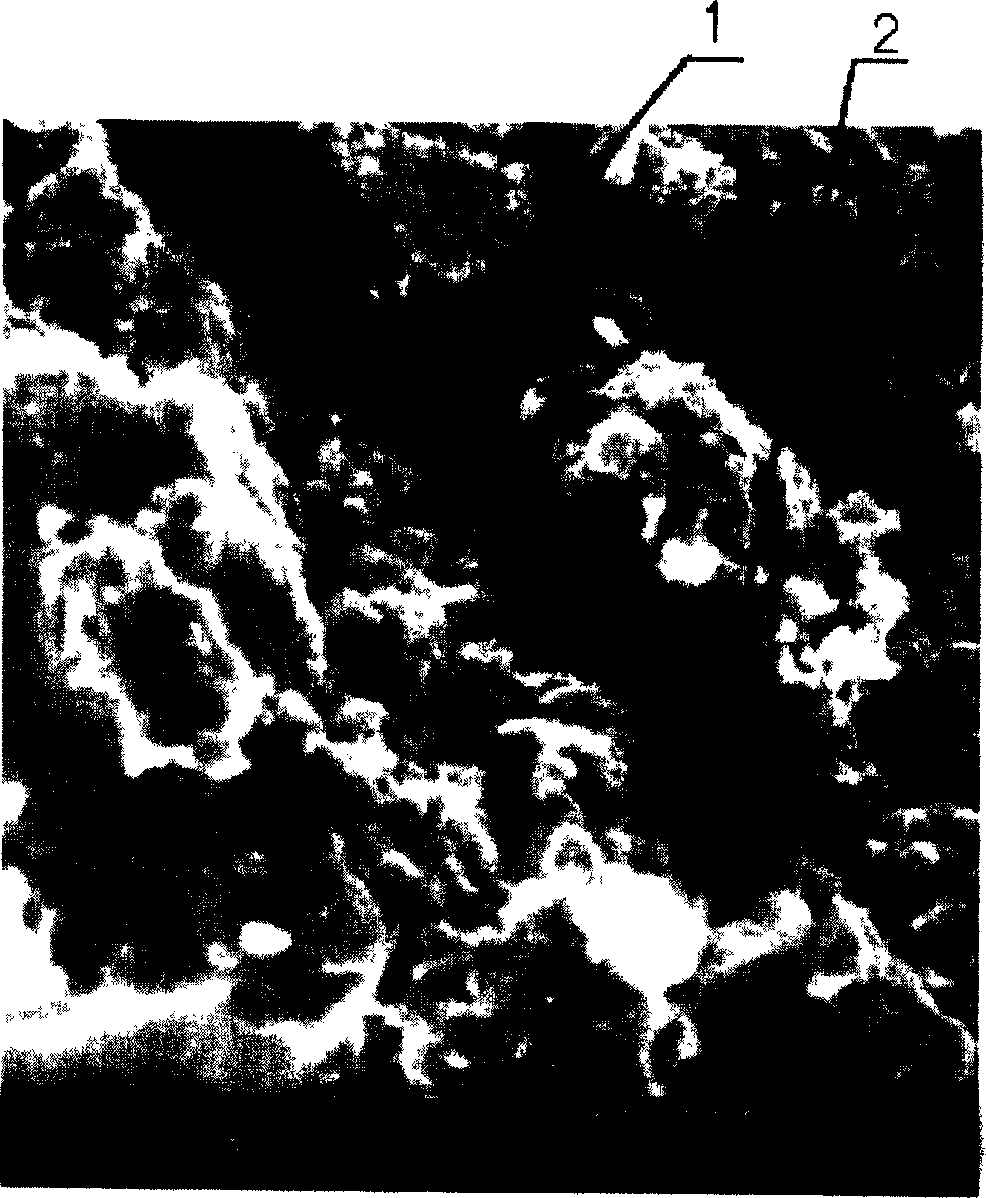

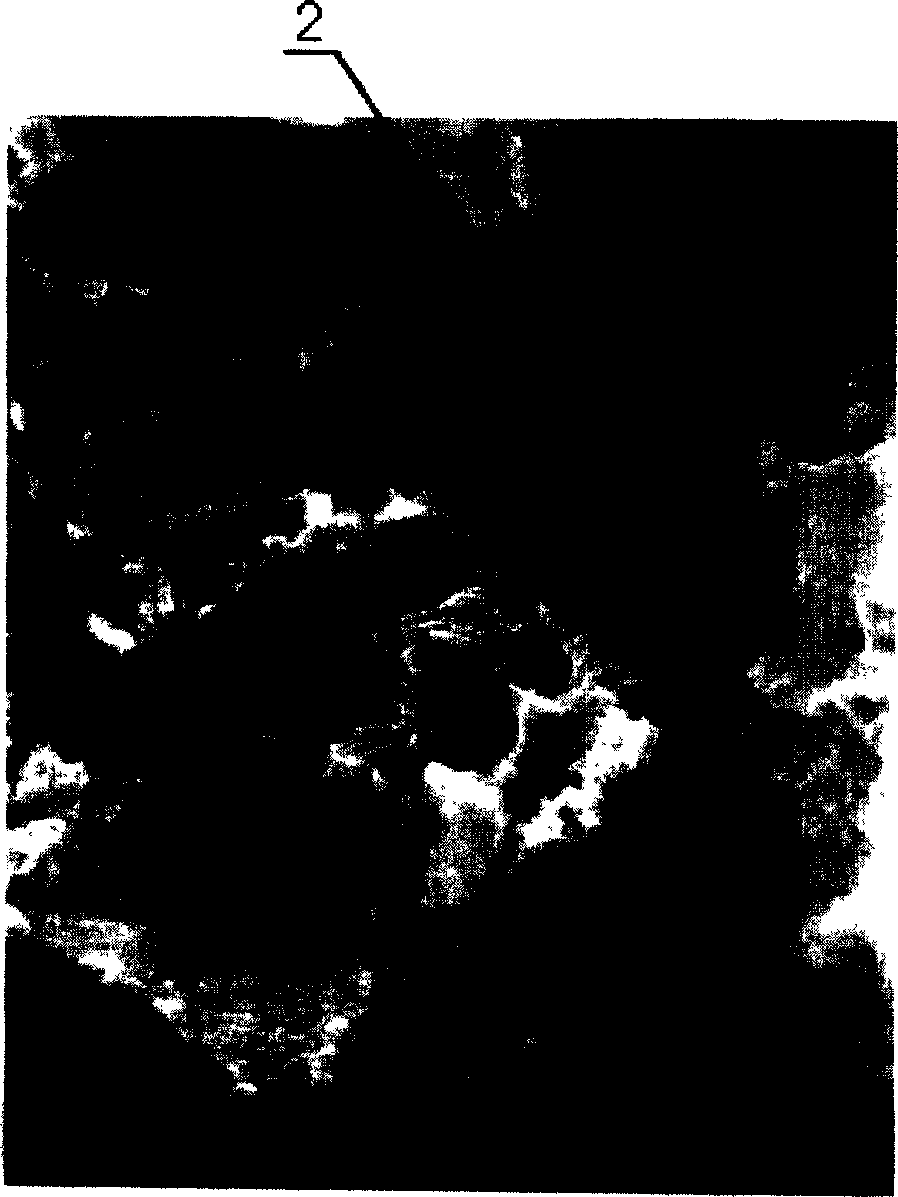

[0022] Such as figure 1 , 2 , the wear-resistant material of the present invention shown in 3, it comprises matrix and the solid lubricant particle body that is compounded on the matrix, matrix is alloy, pottery, rare earth element mixed sintered body with sweat gland type structure micropore, sweat gland type structure micropore It consists of internal micropores 2 and through micropores 1. The internal micropores 2 communicate with the surface of the substrate through the through micropores 1. The micropore diameter of the sintered sweat gland structure is 0.05-8 μm. The solid lubricant particles are compounded in the micropores of the sweat gland structure. The matrix contains alloy, titanium carbide (ceramic material) and yttrium oxide (rare earth element material), and the weight ratio of each component is: 40-60 parts of alloy, 25-40 parts of titanium carbide and 1-2 parts of yttrium oxide. The alloy is high speed steel or stainless steel. The total pore volume rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com