Door of microwave oven with structure for preventing microwave leakage

A microwave oven and microwave technology, applied in microwave heating and other directions, can solve the problems of deterioration of anti-leakage performance, difficulty in folding and forming, low mechanical strength, etc., and achieve enhanced mechanical strength, small microwave leakage, and microwave blocking frequency band width. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

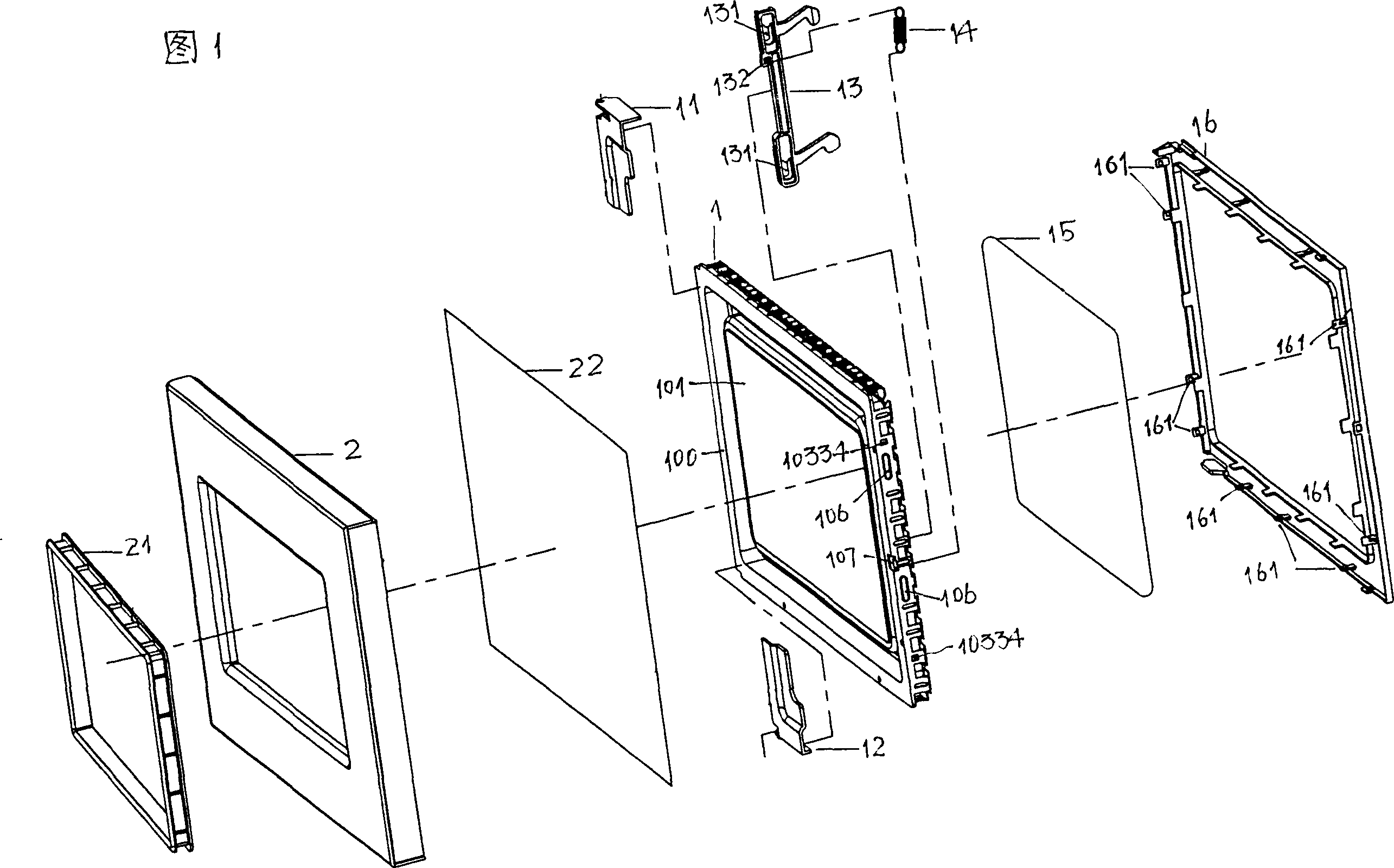

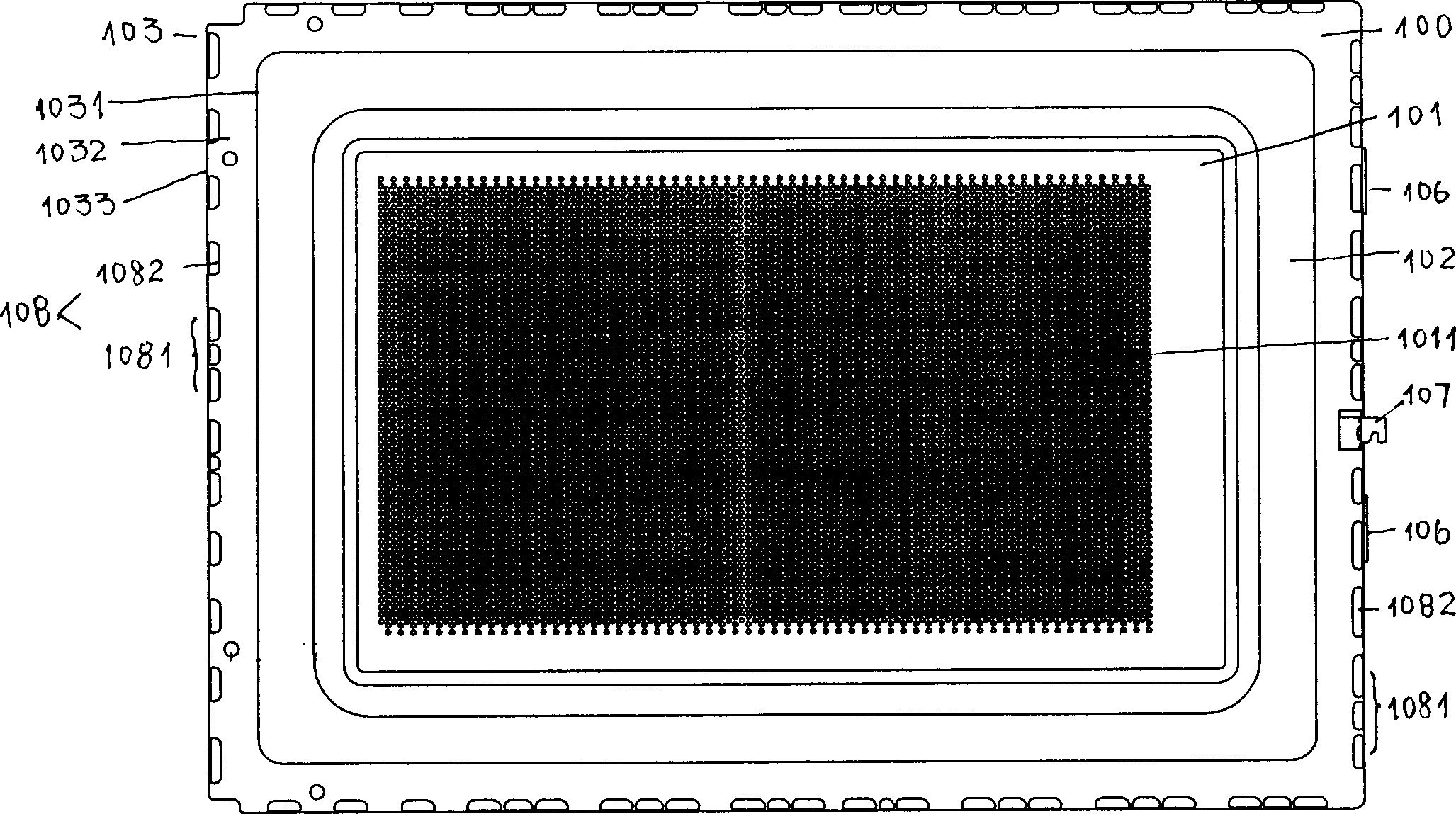

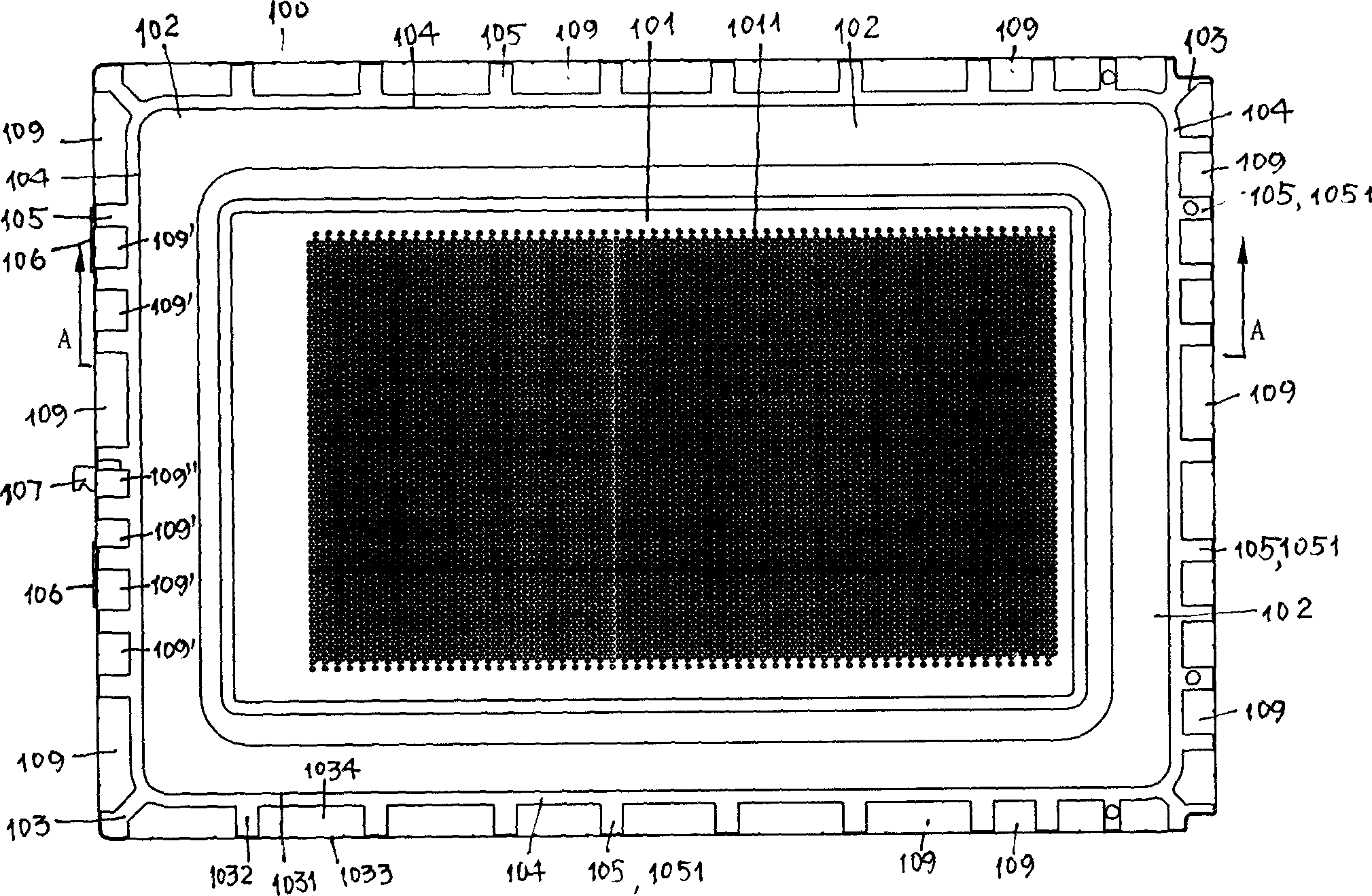

[0023] Please refer to FIG. 1 for the unfolded structure of a preferred embodiment of the microwave oven door with microwave leakage prevention structure of the present invention. In this microwave oven door, the door main body 1 is rectangular and is formed by stamping steel plates; the upper and lower hinge seats 11 and 12 are installed on the upper and lower corners of the left side of the door main body 1, so as to be hinged with the oven body of the microwave oven. Door hook 13 and spring 14 are installed on the right side of door main body 1, so that after door is closed, door is locked at the cooking chamber front opening of microwave oven. The upper and lower parts of the door hook 13 each have a translation guide block 131 respectively stuck in the corresponding elongated translation guide holes 106 on the upper and lower sides of the right side of the door body 1, and the free end of the spring 14 is sleeved on the door hook. 13 on the hook 132 on the top, the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com