Method for improving rolling mill thickness control accuracy using data redundance

A thickness control and data redundancy technology, applied in the control field, can solve the problems of reduced model setting control accuracy, loss of self-adaptive ability, failure of self-learning function, etc., so as to solve the failure of thickness self-learning function and improve the setting accuracy of rolling mill , the effect of model adaptive ability enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

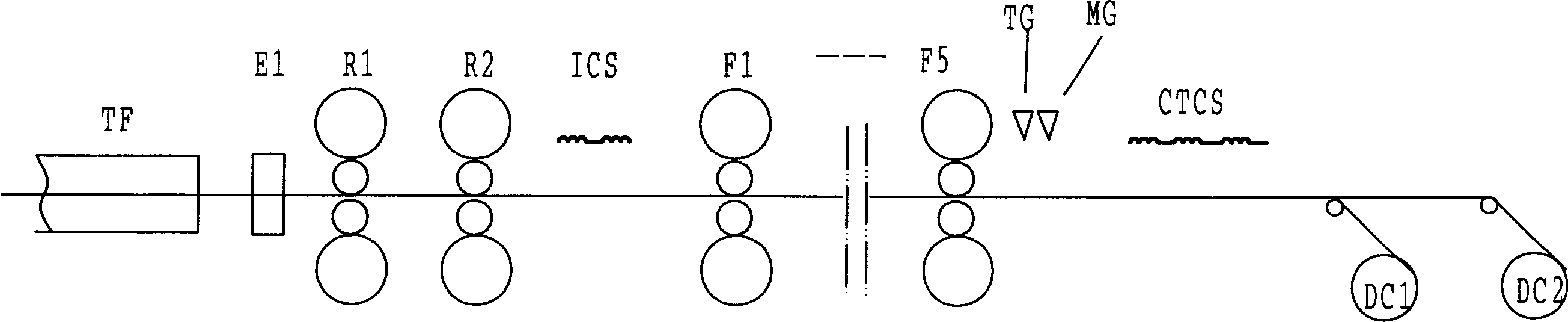

[0018] The rolling mill production line in the present invention includes heating furnace TF, vertical rolling mill, horizontal rolling mill R1, R2, F1~F5, intermediate cooling equipment ICS, laminar cooling equipment CTCS, coiler DC1, DC2, thickness tester TG, multi-functional Tester MG.

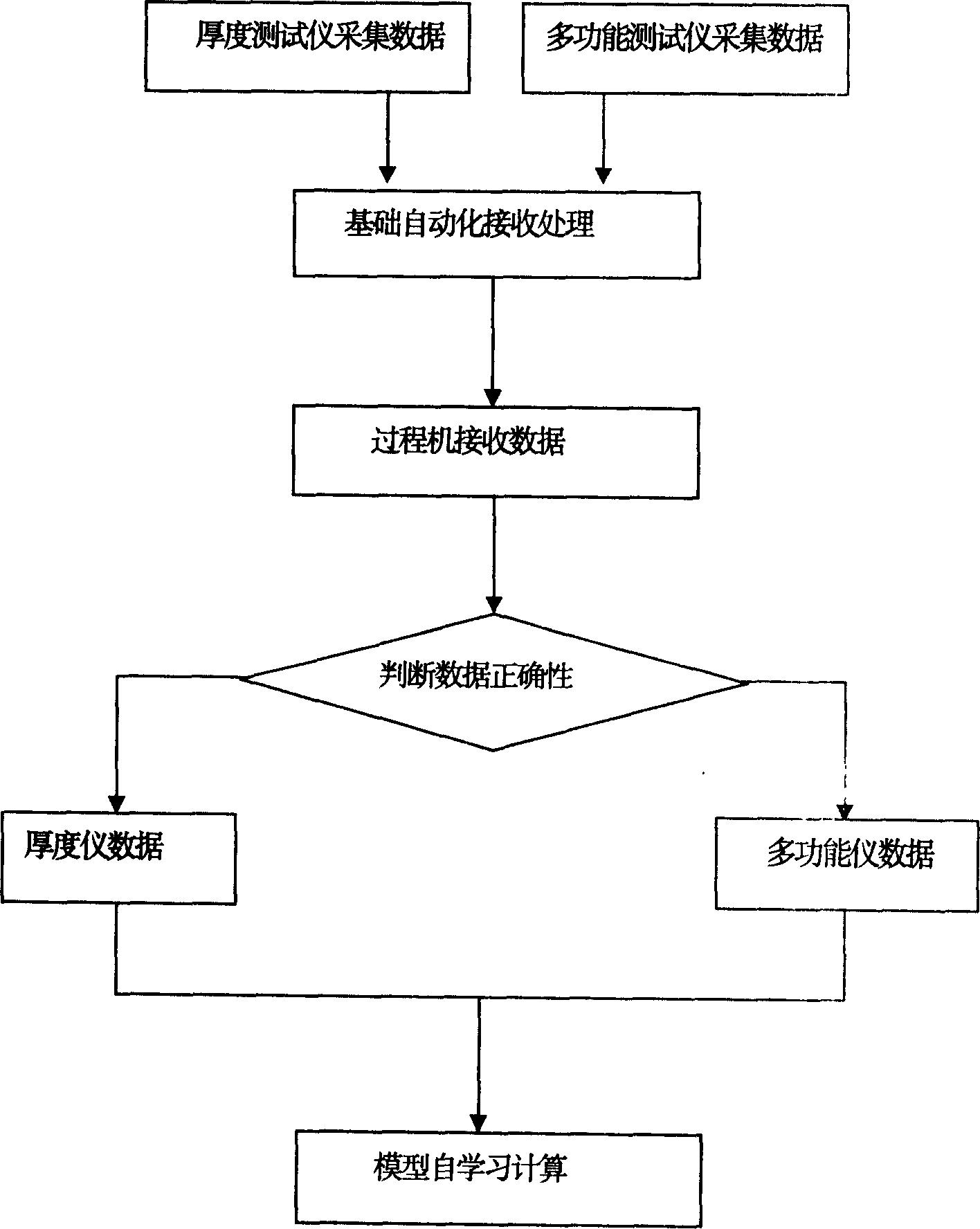

[0019] In rolling mill production, the rolling mill exit multifunctional tester is generally used to measure the crown and flatness of the finished strip, but it also has the function of measuring thickness. Using this feature, when the thickness tester breaks down or the measured actual data deviates too much, the actual strip thickness data measured by the multi-function tester is used as the backup input data for the self-learning function.

[0020] Both the thickness tester and the multi-function tester are installed at the exit of the last rolling mill with a distance of 1.2 meters, and the thickness tester is in front of the multi-function tester. Such equipment configuration determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com