Switch device

A technology of switch devices and components, applied in the direction of contact operating parts, etc., can solve the problems of aggravating the operating feeling and large sliding contact resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

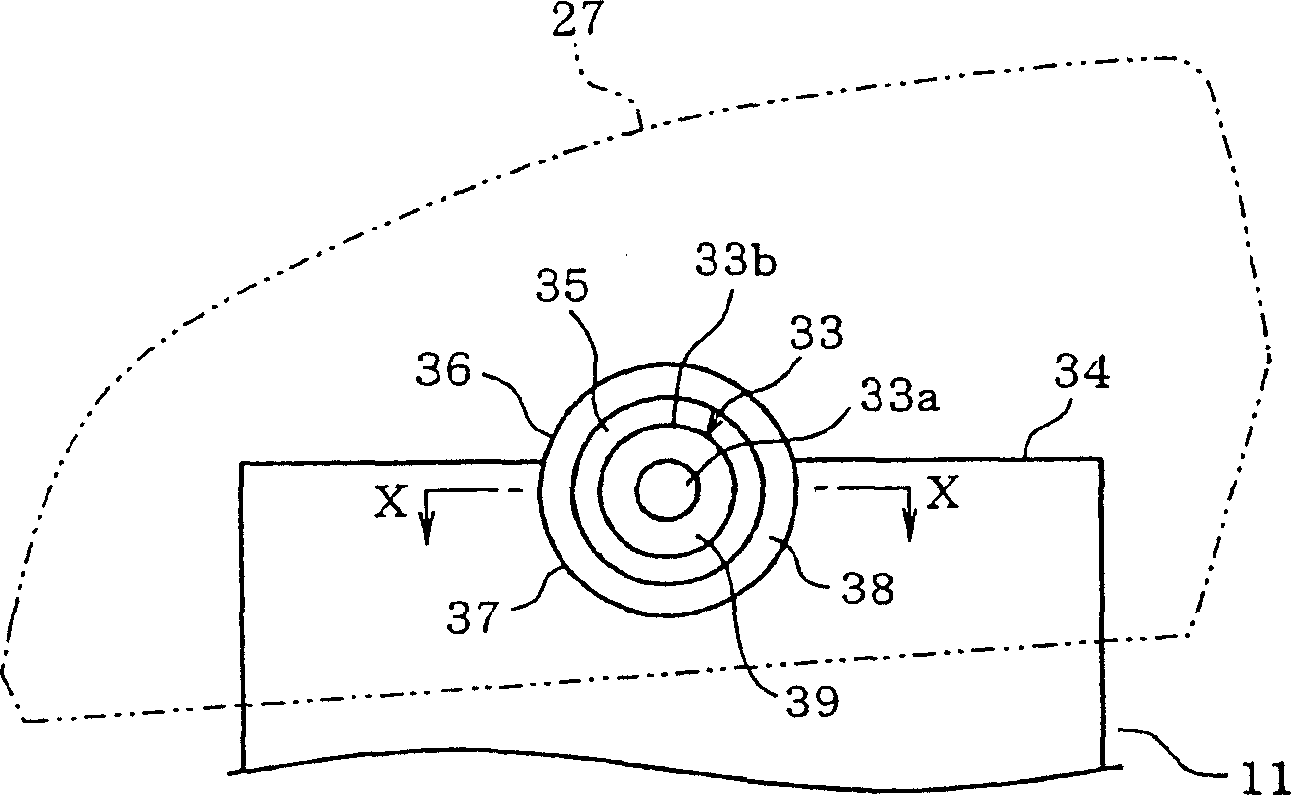

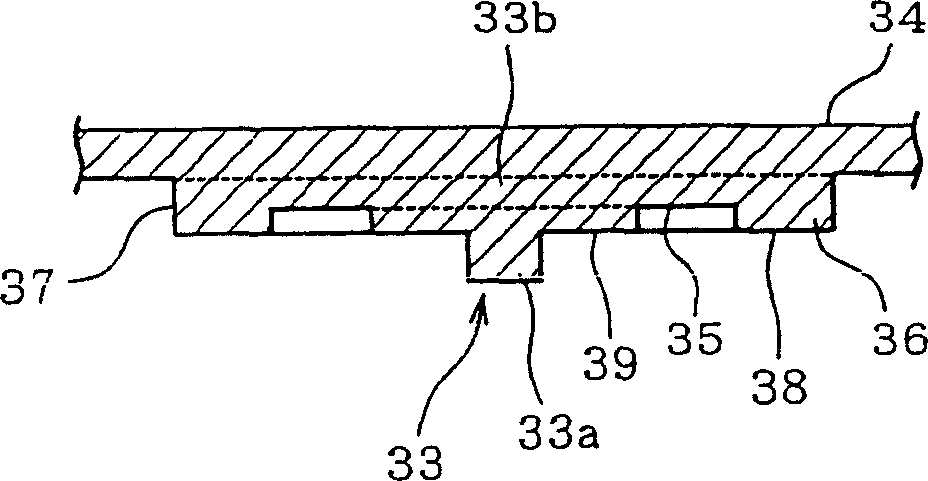

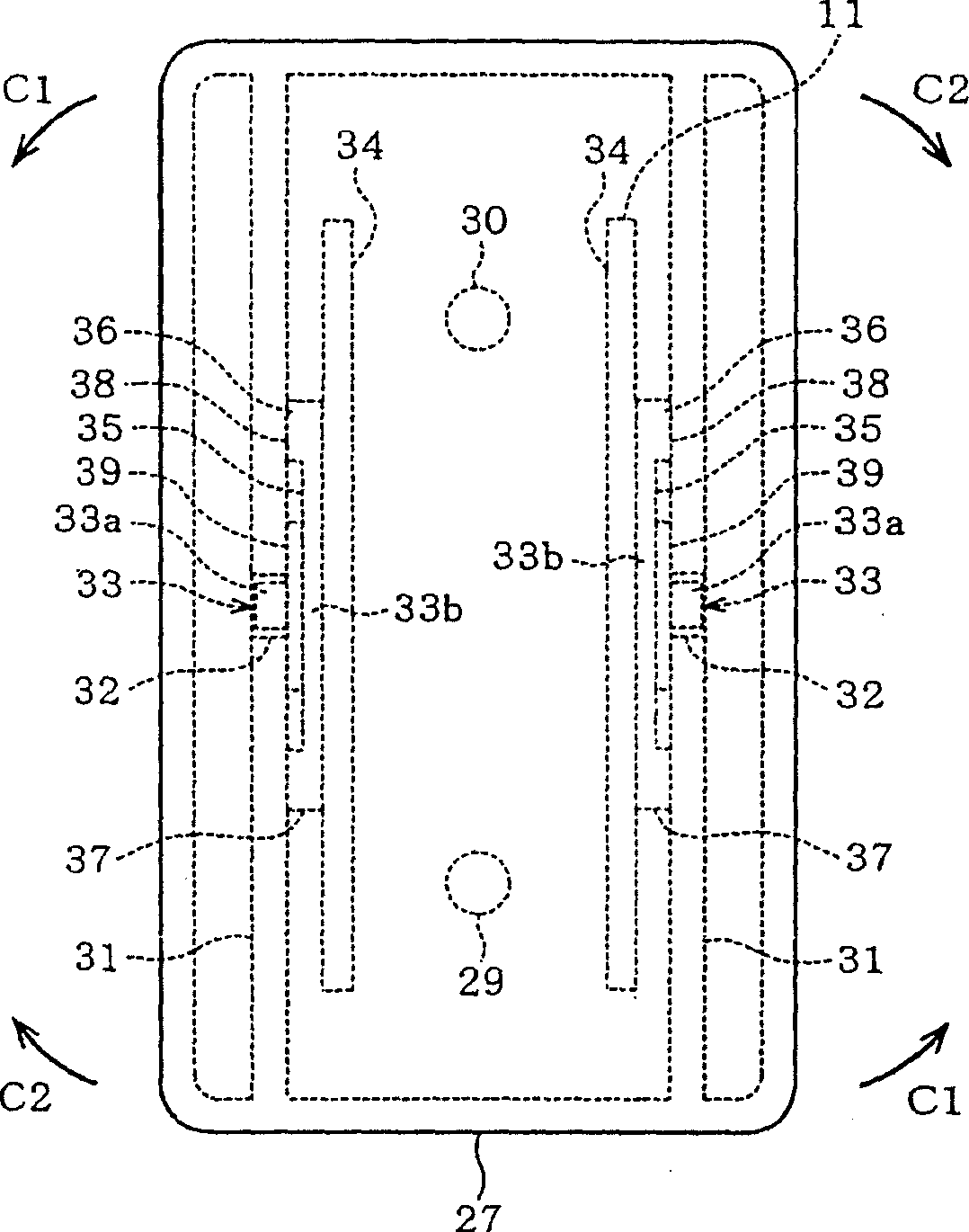

[0021] Below, refer to Figure 1 to Figure 4 An example (one embodiment) of the present invention will be described.

[0022] first, Figure 4 The switch main body 11 is shown, and the circuit board 12 is assembled in the lower side. Several circuit components 13 are mounted on the circuit substrate 12, and at the same time, front and rear ( Figure 4 The left and right in the middle) are separately provided with fixed contacts 14,15. In addition, the circuit board 12 is covered with an elastic sheet 16 made of an elastic material such as rubber, and the elastic sheet 16 forms a contact seat on the above-mentioned fixed contacts 14, 15 via thin bendable parts 17, 18, respectively. 19 , 20 , there are movable contacts 21 , 22 respectively facing the above-mentioned fixed contacts 14 , 15 on the lower surfaces of the contact bases 19 , 20 .

[0023] The switch main body 11 has a push rod guide rail 23,24 on the contact seat 19,20 respectively, so that each lower end of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com