Printing method and apparatus for an ink-jet printer having a wide printhead

An inkjet printer and print head technology, applied in the directions of printing devices, inking devices, printing, etc., can solve the problems of increased image density, inability to increase image density, and increased image density in the best mode 4C.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

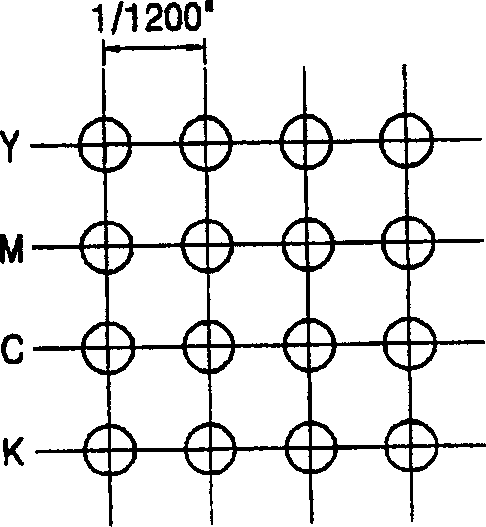

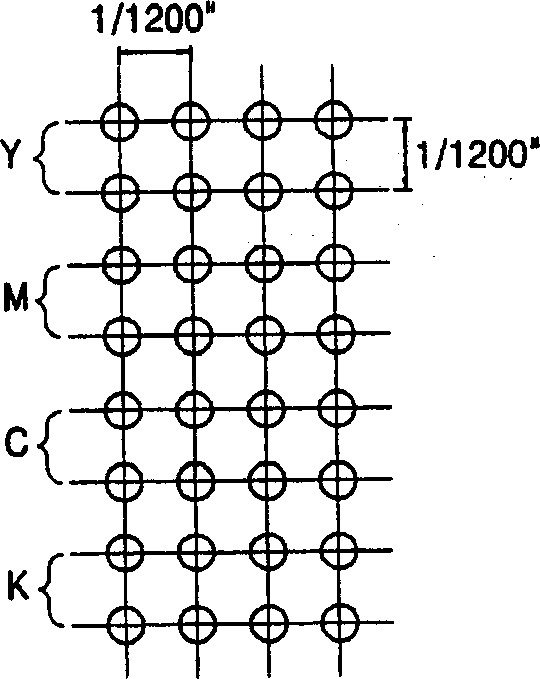

[0041] Figure 5 An elongated column of wide printheads is illustrated printing an array of ink drops on a print medium in accordance with an embodiment of the invention. refer to Figure 5, ink droplets of various colors, such as yellow (Y), magenta (M), cyan (C) and black (K), are sequentially arranged. The ink droplets Y1, M1, C1, and K1 arranged in the first row and the ink droplets Y2, M2, C2, and K2 arranged in the second row are arranged in the main scanning direction at a horizontal pitch Ph corresponding to a predetermined resolution (such as 1200dpi) . In addition, the ink droplets Y2, M2, C2, and K2 of the second row are shifted from the ink droplets Y1, M1, C1, and K1 of the first row by half the horizontal pitch Ph in the main scanning direction.

[0042] The ink droplets of each color in the first row and the ink droplets in the second row are arranged at a vertical pitch Pv corresponding to a predetermined resolution (eg, 1200dpi).

[0043] Figure 6 Illust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com