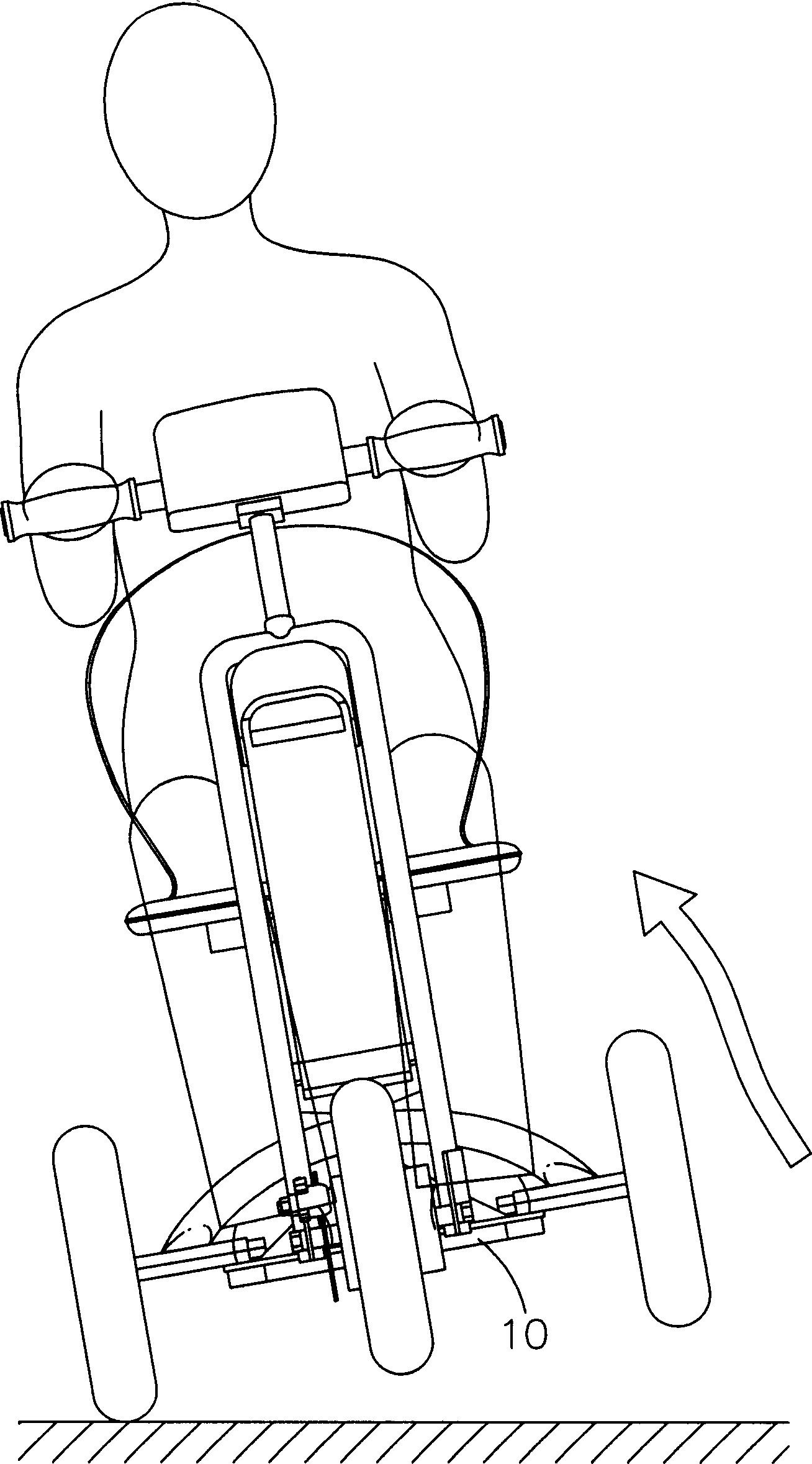

Electric bicycle drive wheel balance frame structure

A frame structure and driving wheel technology, applied to bicycle brackets, bicycle accessories, axle suspension devices, etc., can solve the problems of excessive acceleration of the driver, dumping of the scooter, and defects in driving stability, so as to prevent the failure of the power wheel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

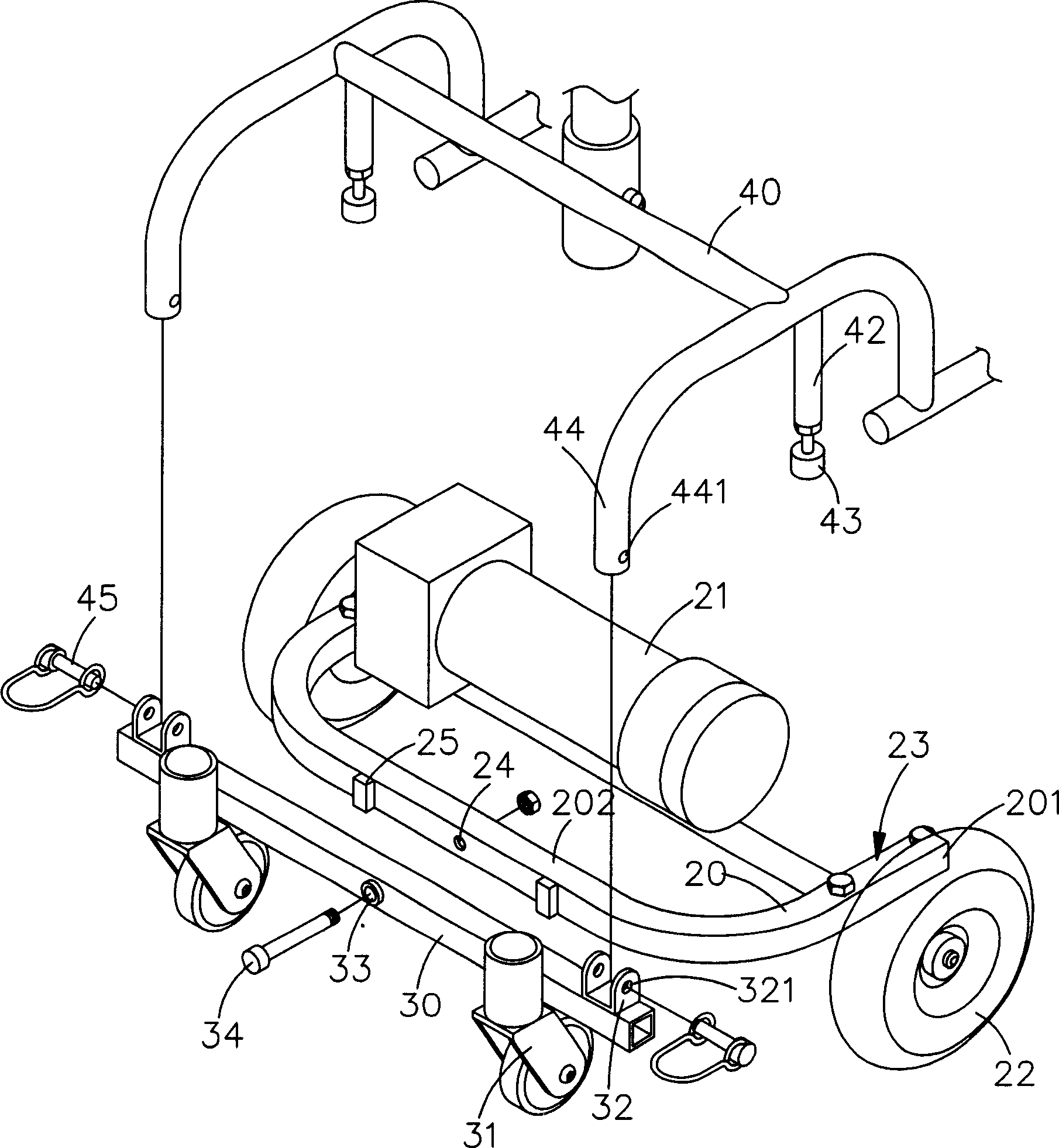

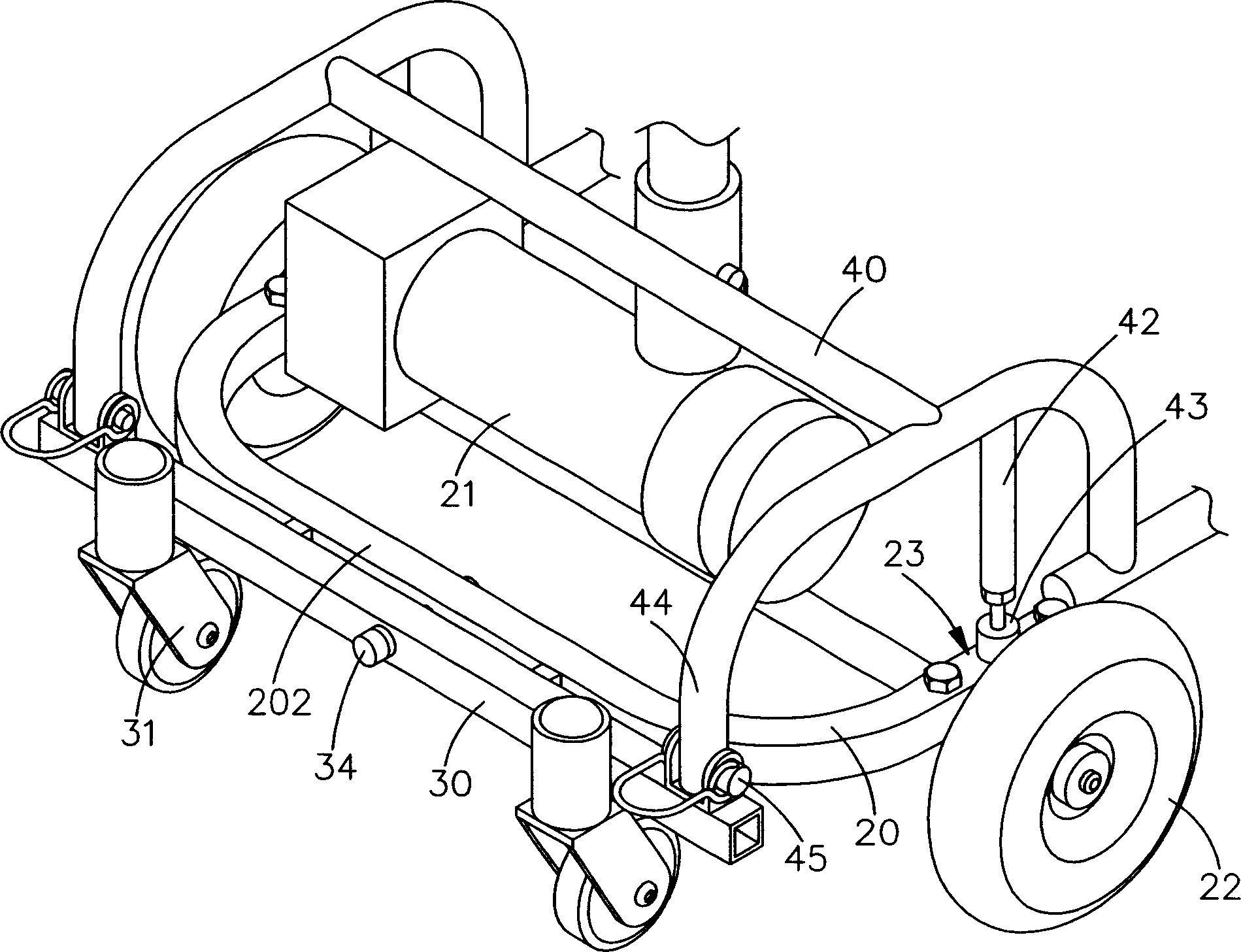

[0046] First please refer to Figure 2-4 Shown:

[0047] The electric vehicle drive wheel balance frame structure of the present invention includes a power wheel frame 20, an auxiliary wheel frame 30 and a weight support frame 40; its structural features are:

[0048]The power wheel frame 20 is a slightly ㄩ-shaped frame body, on which a power motor 21 and a power wheel 22 are installed, and the two protruding ends 201 of the ㄩ-shaped power wheel frame 20 are set at preset positions. There is a top portion 23, and a first pivot hole 24 is opened in the center of the horizontal frame portion 202 opposite to the two protruding ends 201. The axial direction of the first pivot hole 24 is perpendicular to the direction of the wheel axis of the power wheel 22, and the first pivot hole 24 An anti-collision assembly 25 is installed on the side;

[0049] The auxiliary wheel frame 30 is a slightly in-line frame body, and two auxiliary wheels 31 are installed at its rear end, and a pivo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com