Shock absorbing hitch

一种联结器、阻尼器的技术,应用在升降机系统领域,能够解决增加成本和人力、结构要求、液压系紧装置昂贵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

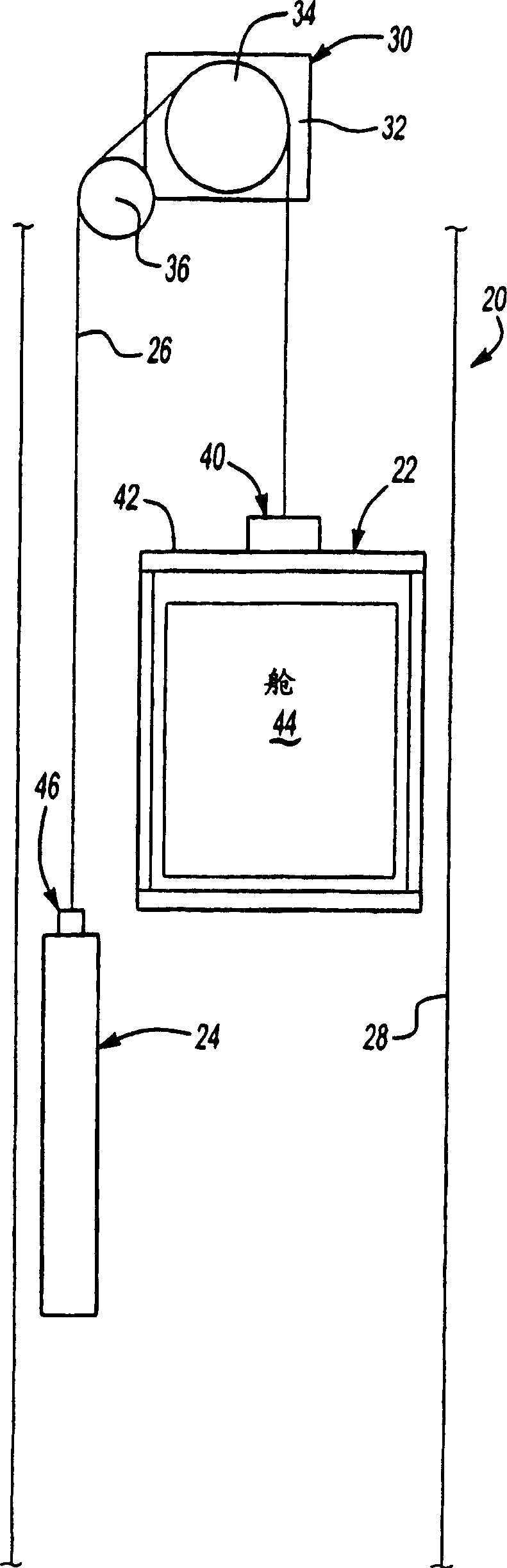

[0021] figure 1 An elevator system 20 is shown schematically, including a car 22 and a counterweight 24 . Load bearing members 26 , such as ropes or straps, support the car 22 and counterweight 24 for desired movement within the hoistway 28 . A conventional machine 30 includes a motor 32 and drive wheels 34 to effect the desired movement of the car 22 and counterweight 24 within the hoistway 28 in a conventional manner. This illustrative example includes guide pulleys 36 which guide the carrier part 26 as required.

[0022] The carrying member 26 in this example has one end connected to the car 22 and the other end connected to the counterweight 24 . A terminal device 40 connects one end of the carrier member 26 to a frame 42 of the car 22 . A portion of the cab 44 of the cab 22 is supported by the frame 42 in a conventional manner.

[0023] An end fitting 46 secures the opposite end of the carrier member 26 to the counterweight 24 .

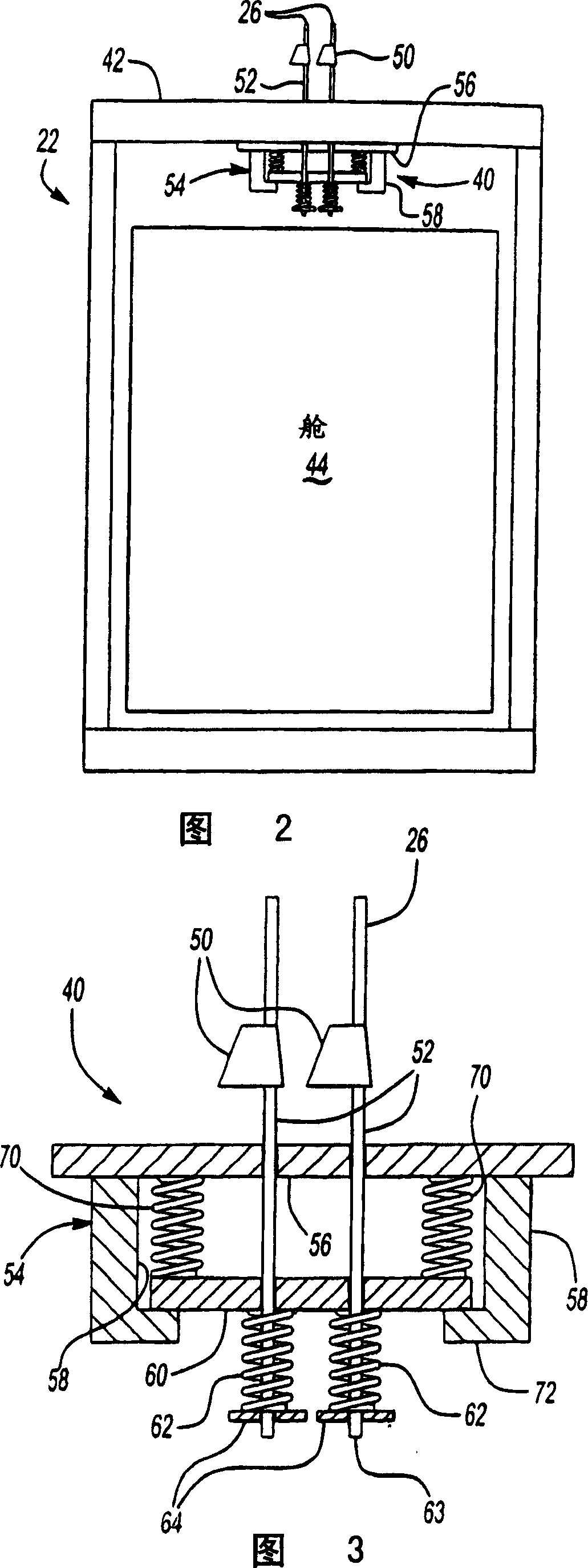

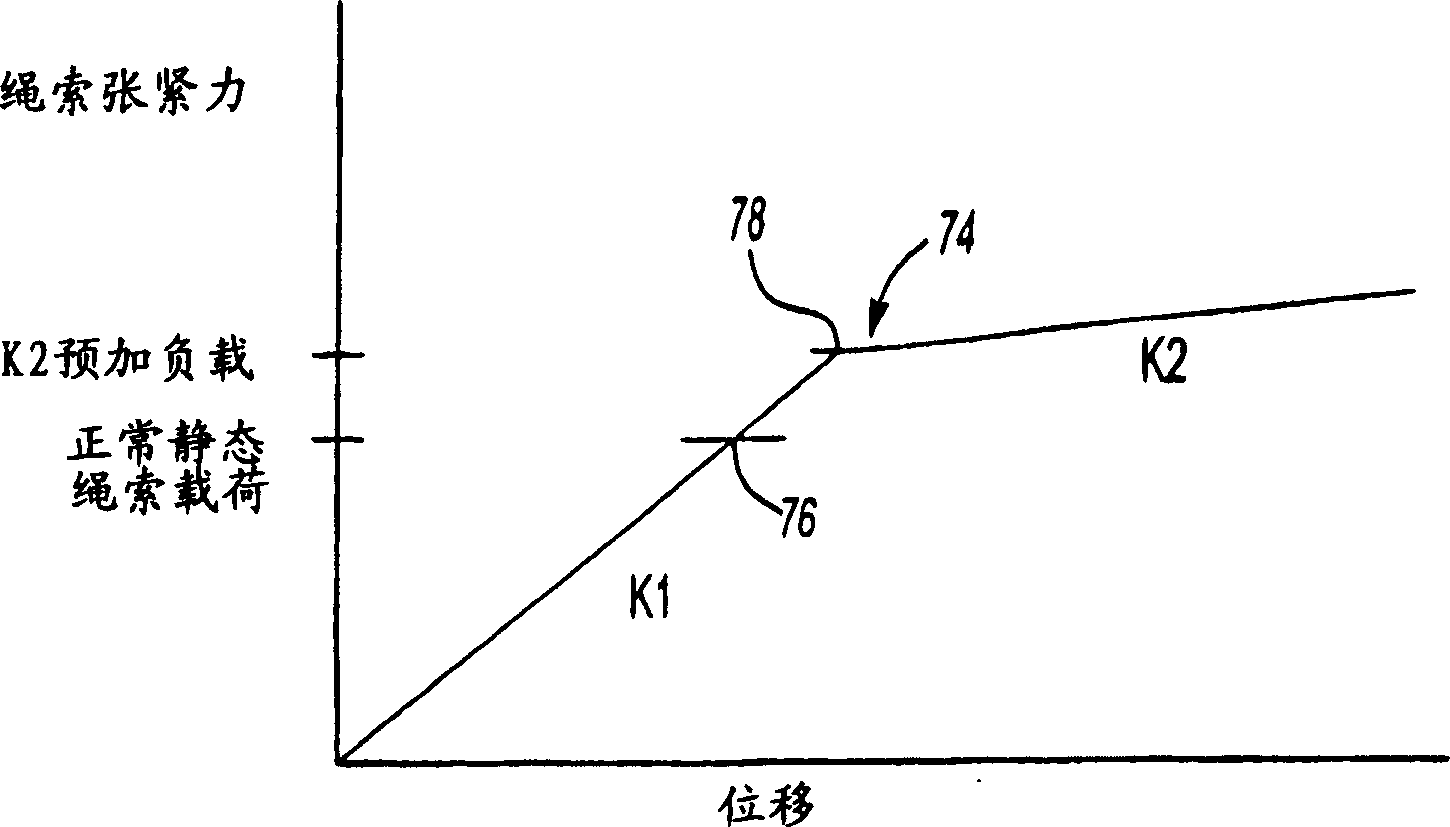

[0024] Referring to FIGS. 2 and 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com